Pump service & repair, Figure 38 figure 40 – Alamo HYDRO 15 User Manual

Page 36

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 2 - 20

PUMP SERVICE & REPAIR

17.

Lightly coat the gear journals with grease. When placing the

Bearing housing

(figure 10 item 13)

over gears,

use caution

so you

don't hit and damage gear shaft journals. Place the bearing carrier

onto gear shaft journals of the drive and the driven gears.

Be sure

to align the dowel pin holes

over with dowel pins. When the parts are

parallel squeeze them together or alternately tap over each dowel

until the parts are together.

DO NOT

use excessive force to put

housing together, if light taping won't do it something is wrong

(figure

42).

18

Insert the 4 studs, 4 Lockwashers & 4 Nuts

(See figure 23A)

that

connect the previous sections. Tighten the stud nuts in alternating

pattern until Torque of the nuts to 3000 in. lbs. (250 ft. lbs.)

19.

Coat the connecting shaft

(figure 10 item 14)

use light coat of

grease, insert it into spline of drive gear. Make certain that gasket

seals are coated with clean grease and installed into second gear

housing as instructed in

step 12.

Position and place second gear

housing

(figure 10 item 16)

making certain the dowel pins are kept

aligned between two castings

(figure 43 & 44)

. Housing should fit

flush to bearing housing.

MAKING CERTAIN

the marks made to

keep the components in the same orientation when re-assembled

are aligned

(figure 23A)

.

20

Place the thrust plate

(figure 10 item 7 & 8)

into the gear housing

as

per step 14.

Coat the

journal of the drive gear

and the driven gear insert

with light coat of grease.

Figure 39

Figure 37

Figure 41

Figure 42

Gear Side

Smooth

Channel Seal

Side Grooved

Smooth Side

Channel Seal

Outward

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

Thrust Plate

Figure 38

Figure 40

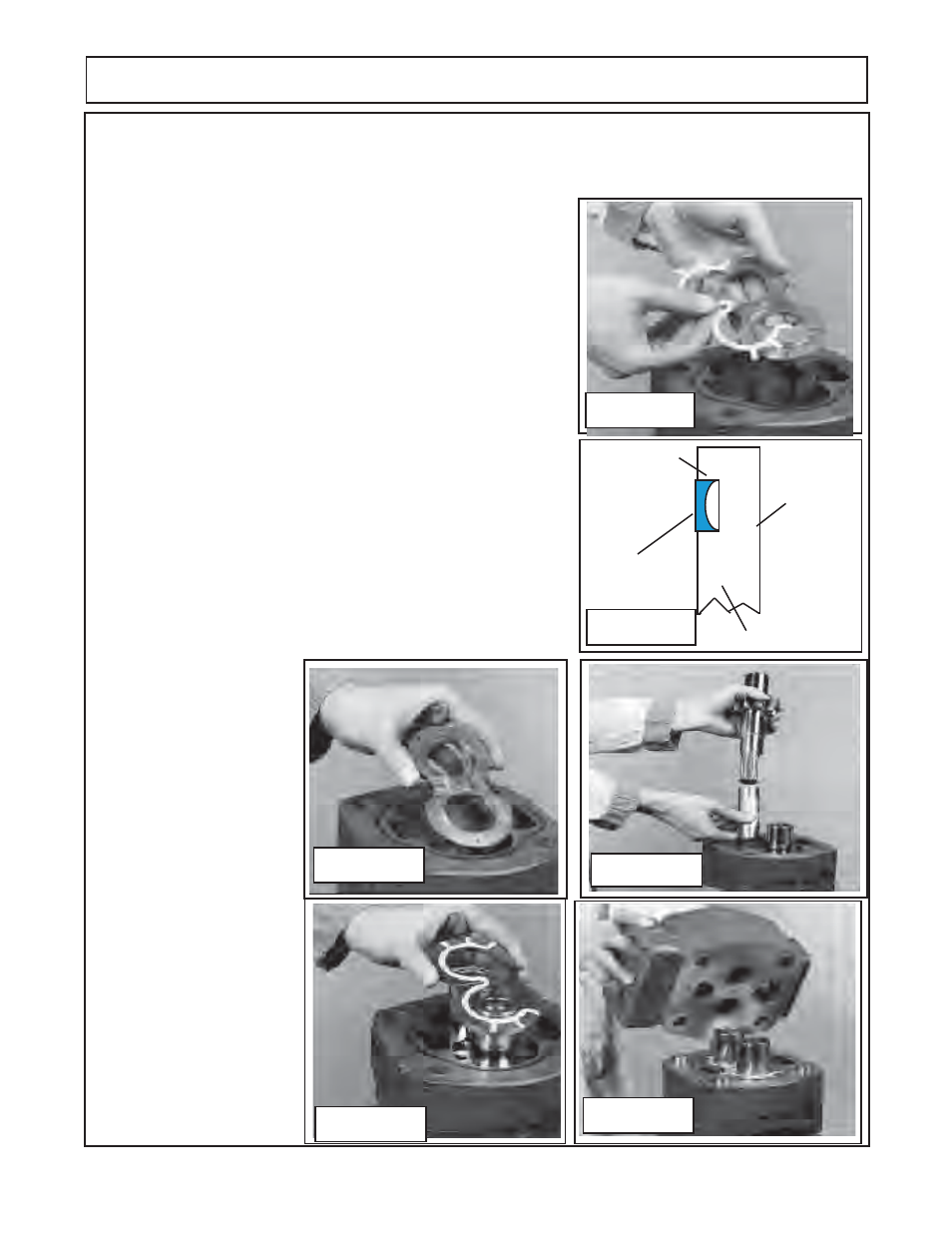

16.

Slip the next thrust plate with the channel seal installed

(figure 10 item 7 & 8)

over the gear journals and into

the housing bore. The flat side of the seal should face up with the relief groove of thrust plate facing the outlet

side. Check the gear housing gasket seal

(figure 10 item 10)

is still in place on gear housing

(figure 24 & 41).

the drive gear aligning the

splined shaft end over the

splined connecting shaft.

Insert the driven gear into

the gear housing aligning

gear teeth with the drive

gear.

DO NOT

force the

gears in, they must slide

in smoothly and mesh

together

(figure 44)

. Make

certain the gears are

seated completely down

and against the thrust plate

face.