Blade & blade carrier service & repair, Figure 4, Figure 5 – Alamo HYDRO 15 User Manual

Page 135

Section 9 - 3

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

CAUTION!

Blades should always be replaced in pairs. Blades of different weights can cause serious

imbalance and damage to the machine and personnel. When replacing the blades, also replace the

blade bolt, nuts and washers. Once the nut has been removed from the blade bolt, it will not fasten

tightly on the bolt again. Never weld or modify the blades. The blades are made of a high strength

steel and heat treated to give maximum strength and resistance to chipping and wear. Any welding

or surfacing applied to the blades can severely reduce its strength. A blade failure could result in a

blade segment being thrown at high speeds out from under the machine.

This is a good time to check the spindle to make sure it is properly tight. To do this, grab the blade bar

and pull outward and push inward. See Figure 6. There should be no noticeable movement. If the spindle is

loose, refer to assembly and disassembly of Spindle in previous Service & Repair section.

Blade & Blade Carrier Service & Repair

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234567

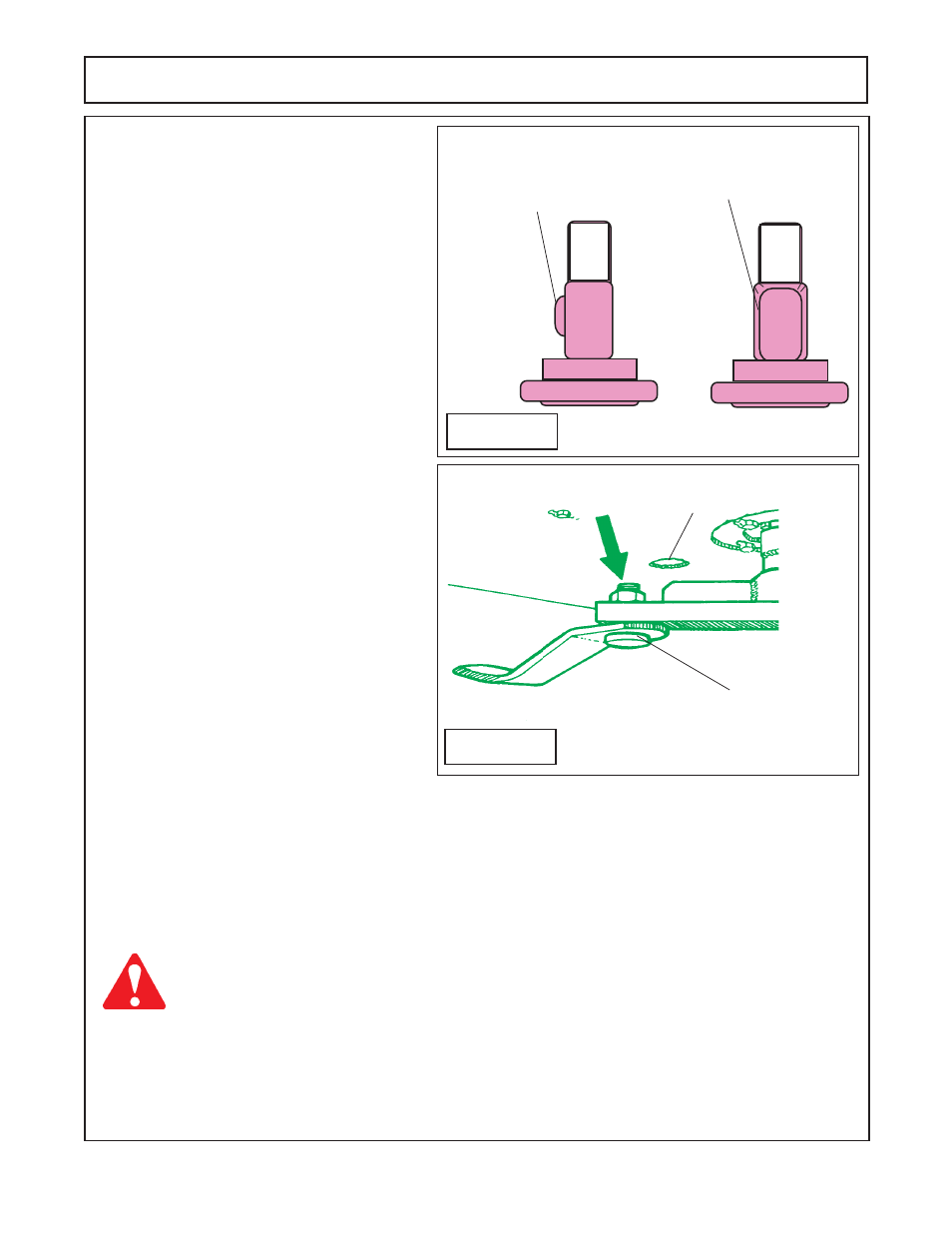

4.

Blade Bolts. There is the square

shanked blade bolt that is currently being

used (figure 4) and the round keyed shanked

bolt that was used in earlier production (fig-

ure 4). Both bolts will have the same torque

rating. Both bolts need to be lined up with

the blade bolt hole when being installed and

tightened. The Keyed blade bolt is very criti-

cal that the key be aligned with the keyway

in the hole. If keyed bolt is not aligned it will

damage the bolts and/or the hole. The Sq.

shanked bolt is important that it be aligned

with the hole when tightening. Changing the

blades is usually a two man job. Access to

the blade bolt Nut is through the access

hole (that is covered) on top of the deck. The

easier method is to use an air impact. It will

usually require you to turn the blade carrier

to align bolt with hole

(figure 5)

. Torque

Blade Bolts to 300 ft. lbs.

5.

Blade Condition. The condition of the

blades, blade bolts and other blade carrier

components are very critical.

Never mix new

and used blades on same carrier,

blades on

the same carrier must be closely matched

for weight or they will cause a un-balance

vibration. If the mower has a vibration do not

run the mower until the cause of the vibra-

tion has been corrected.

A vibration in a

mower will cause metal fatigue and welds to

crack.

The amount of time it takes to show

up depends on the severity of the vibration.

6.

Blade Inspections, the blades should

be closely examined each morning before

Figure 4

Key Shanked Blade

Bolt (Key is built into

bolt shank) Old Style

Square Shanked

Blade Bolt, Current

Style

Figure 5

Blade Bolt Axcess

Hole

Align Blade Bolt

with Axcess Hole

start up

(figure 5).

The Blade should be free of deep chips, cracks or abnormal bends. If the blades are sharp

they will require less power while moving. Blades should be replaced when they become excessively worn,

bent, or deformed. Blade are designed to turn the direction of cut as according which way the blade carrier

turnsas decided by the hydraulic motors direction of travel, CW or CCW. Make certain that the blades are i

nstalled on the correct blade carrier to match the direction of rotation. Make certain the holes in the blade

carrier are not deformed or damaged. If any holes in carrier are not in serviceable condition, bolts will not stay

tightened. DO NOT operate the mower with damaged holes in blade carriers.