Hydraulic tank, Figure 5, Figure 6 – Alamo HYDRO 15 User Manual

Page 107

Section 6 - 3

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Fill Hydraulic Tank Return Filters - Service & Repair

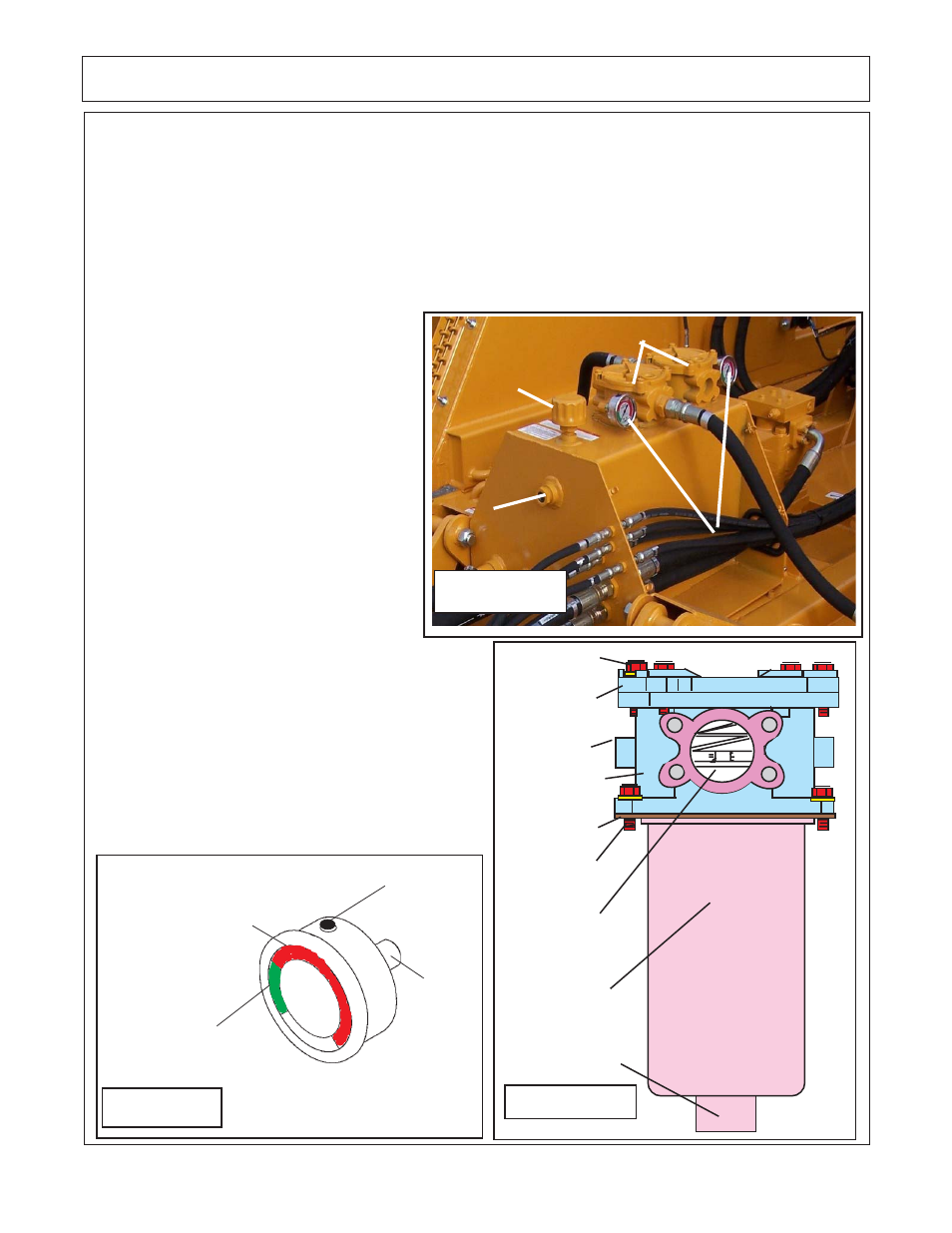

Hydraulic Tank:

Hydraulic tank is bolt on assembly, hydraulic tank houses return

filters

(figure 4 & 6),

oil level sight

glass and two return oil pressure gauges. The filler cap is a breather type. The center section returns through the

back filter and the wings return through the front filter. Each filter will have a return pressure gauge

(figure 4 & 5).

1.

Clean The Machine - The deck and hydraulic tank should be cleaned off at least once a day. Remove all

foreign material from the deck, Tank and structural members. Never allow collected grass and dirt to remain

in the deck or around the hydraulic tank. This material will decompose forming ammonia compounds which

will erode the paint and metal deck it will also prevent the tank & oil cooling tubes from dissipating heat

Green Area "Good"

(0 psi to 15 psi)

Red Area "Replace Filter"

(16 psi to 60 psi)

Vent (Cut Off

Top)

1/4" NPT

Return Pressure Gauge

(Glycerin Filled)

FIGURE 5

efficiently. This material is also a source

of contamination any time the hydraulic

system is opened or service. Keep the

deck area clean and always clean before

starting any service or repairs.

2.

To change filter cartridge it is not re-

quired to unbolt filter assembly from tap. It

will require the removal of the filter housing

cover (figure 6) by unbolting the filter cover

bolts (figure 6). There is a spring under the

cover that presses down against the filter

cartridge, hold down on the filter cover as

you unbolt it. Lift the cover off and the spring

under it. Hold a small drain pan as close to

the filter housing as possible, this will allow

you to pull the filter cartridge straight up out

of housing and move it over the drain pan as

quickly as possible. This will limit the amount oil

leaking down on tank and deck.

3.

Return filter gauge is low pressure gauge. It will

read high (in the red) when oil is cold and unit is first

started. Run unit at lower RPM until oil reaches normal

operating temperature. Recheck gauge, the return

should be reading in the green, if it is not check

system for blockage or other problem restricting the

return flow. NEVER connect the pressure side direct

to the colling tubes on deck, this will damage them.

FIGURE 4

Return Pressure Gauges

Sight Gauge

Return Filters

Filler Cap

Filter Asy to

Tank Bolts

Filter Asy to

Tank Gasket

Filter Housing

FilterReturn

Gage Port

FilterHousing

Cover

Filter Housing

Cover Bolts

FIGURE 6

Filter Oil to

Tank Return

Oil to Filter Asy

Return Port

Return Filter

Cartrige Inside