Speed increaser service & repair, Figure 6, Figure 7 – Alamo HYDRO 15 User Manual

Page 120

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 7 - 10

Speed Increaser Service & Repair

Re-Assembly for Replacement of Components!

IMPORTANT! Make certain all components have been cleaned, inspected and replaced as required. All

parts must be dry of any cleaning agents. All covers should be cleaned of oil and/or grease.

1.

Make certain the covers

(figure 4 items 6, 7 & 9)

are completely cleaned around the gasket / shim area.

Make certain the mounting surface is flat and undamaged. This is important to assure the covers seal when

installed later.

2.

Install seals into covers, there are three seals

(figure 4 item 10)

, these seal are all the same and can be

install in either of the two open covers

(figure 4 item 9)

or in the pump mount flange

(figure 4 item 6)

. The

seals will install

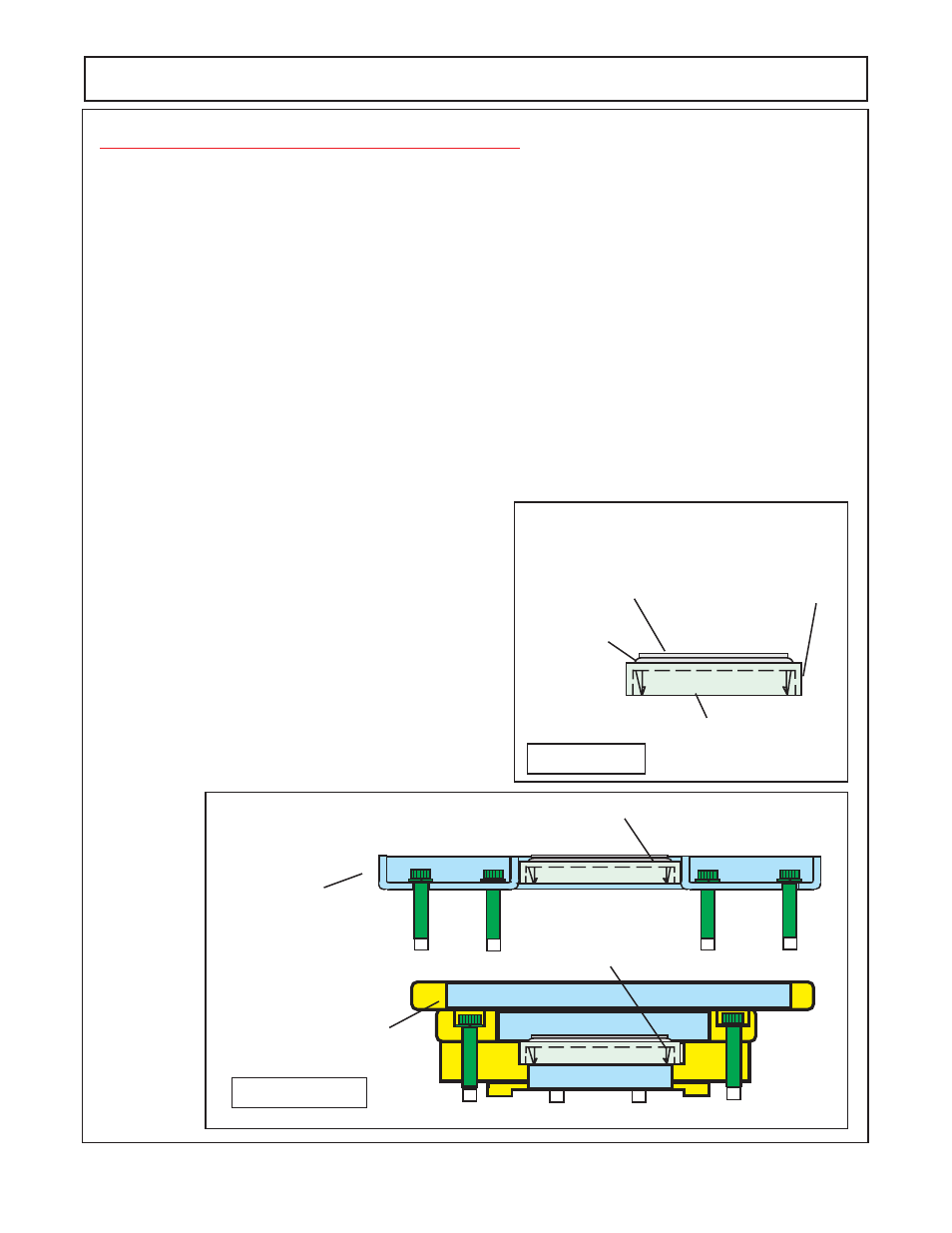

(figure 6)

with the flat side outward. The hollowed side will install inward toward the gears.

Coat the ID of the seal with clean light coat of grease. Coat the OD

(side figure 6)

of seal with Locktite ™ 801

sealer or equal, this will help keep seal from leaking

(figure 6)

. Use the proper dia seal driver to install the

seal. Set the covers with the seals installed aside for now.

3.

Install Bearing Flange Mount

(figure 7)

with new seal already installed to the housing half with the Allen

head

5/16" -NC X 3-1/4" Gr. 5

bolts & lockwasher

(figure 4 item 29 & 30)

There are total of 24 of these bolts

used on speed increaser, they are the same size and length bolts. Make certain the housing half, the one

open cover and the pump mount flange are clean and

FIGURE 6

Flat side

Outward

This Side Inward

Toward Gears

Coat out side dia

of Seal w/Locktite™

801 or Equal Sealer

Coat ID of seal with

light coat of

Clean Grease

free of the old gasket. Install new gaskets

(figure 4

item 24)

to the covers, use light gasket sealer when

installing the covers. Only the one open cover and the

pump cover flange can be installed and torqued to the

housinf half

(figure 4 item 16)

at this time

(figure 9).

Coat the bolt threads with a thread light sealer The 5/

16" bolts will

torque 12 to 15 ft.

lbs. These are to be

torqued in a criss cross pattern

(figure 8).

Do this in

increments to keep the flange and cover m mounted

square and prevent warpage. The pump mount flange

and the open cover mount and toque the same

12 to 15

ft. lbs.

After tightening the open cove and the pump

mount flange make certain the ID of the seals are

coated with light coat of grease.

1234

1234

1234

1234

123

123

123

123

123

123

123

123

123

123

Pump Mount Flange

Open Cover

(Qty 2)

123

123

123

123

123

123

123

123

123

123

123

123

Seal Install From Top

Seal Install From Top

FIGURE 7