Wing lift & fold cylinder repair – Alamo HYDRO 15 User Manual

Page 83

Section 5 - 9

HYDRO 15 (Service Manual) 10/06

© 2006

Alamo Industrial

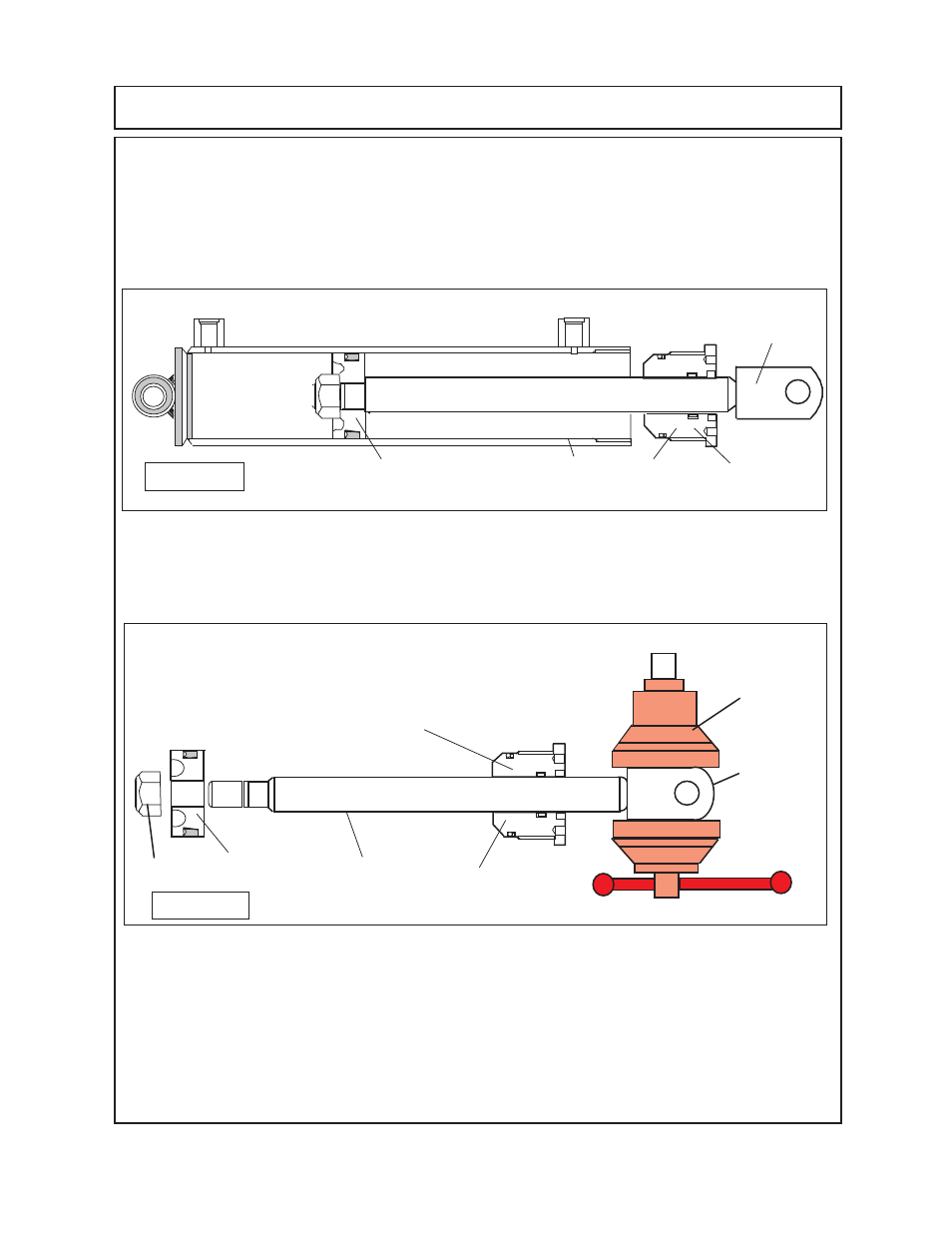

6.

Slide the cylinder head

(figure 3 item 4)

off the cylinder rod (

figure 3 item 3)

in the direction of

the piston.

DO NOT hammer on cylinder head or cylinder rod.

Cylinder head should slide by hand

with a minimum amount of effort, if it will not slide by hand check the cylinder rod for damage, scored

or bent. If cylinder head is forced over a damage area or bend it could damage cylinder head.

5.

Remove the 3/4" RH Thread Piston Retaining Locknut

(figure 3 item 7)

. The piston

(figure 3

item

6)

will not slide off of the cylinder rod weldment

(figure 3 item 3)

. Care must be taken when

removing the piston so as not to damage it,

DO NOT hammer on piston or cylinder rod

. The piston

was pressed on cylinder rod using a loctite 271 or equivalent. Piston

WILL HAVE TO

be pressed

off of cylinder rod, when pressing piston off make certain to support piston so as not to damage it

and use something to protect the threads on cylinder rod from being damaged by press. Support

the cylinder rod while in press from falling and damaging piston nut threads.

WING LIFT & FOLD CYLINDER REPAIR

Clean & Inspect Cylinder Components: (LH or RH Wing Cylinder)

1.

Inspect the barrel, check for scratches, severe wear areas, distorted tube dia. If no serious

damage is detected clean the Barrel

(figure 4 item 5)

, this can be done with solvent or with pressure

(Steam) washer. Inspect the tube closely, look at the OD of the tube for any dents or bulges. Inspect

the ID of the tube for serious wear. Inspect the base mount to make certain it is not worn or damaged.

Inspect the hose ports condition, check the threads in these ports.

2

If water was used to clean the barrel make certain all water (moisture has been dried off,

DO NOT

use anything that has lent ot dirt on it to dry the Barrel ID, it is recommended that air be used. Put

a light coat of clean hydraulic Oil (See Specifications for recommended type of oil for this model) on

the ID of the barrel.

12

12

12

12

12

12

12

12

12

12

1

1

1

1

1

12

12

12

12

12

1234567890123456789012345678901212345678901234567890123

1234567890123456789012345678901212345678901234567890123

1234567890123456789012345678901212345678901234567890123

123456

123456

1234567

1234567

1234567

1234567

4

3

Figure 2

5

Cyl head screwed

out f/ barrel

6

1234567

1234567

1234567

4

3

Figure 3

Cyl Head screwed

out f/ barrel

6

Vise

Cyl Rod

Clevis

Weldment

123456

123456

123456

123456

123456

12345

12345

12345

12345

12345

7