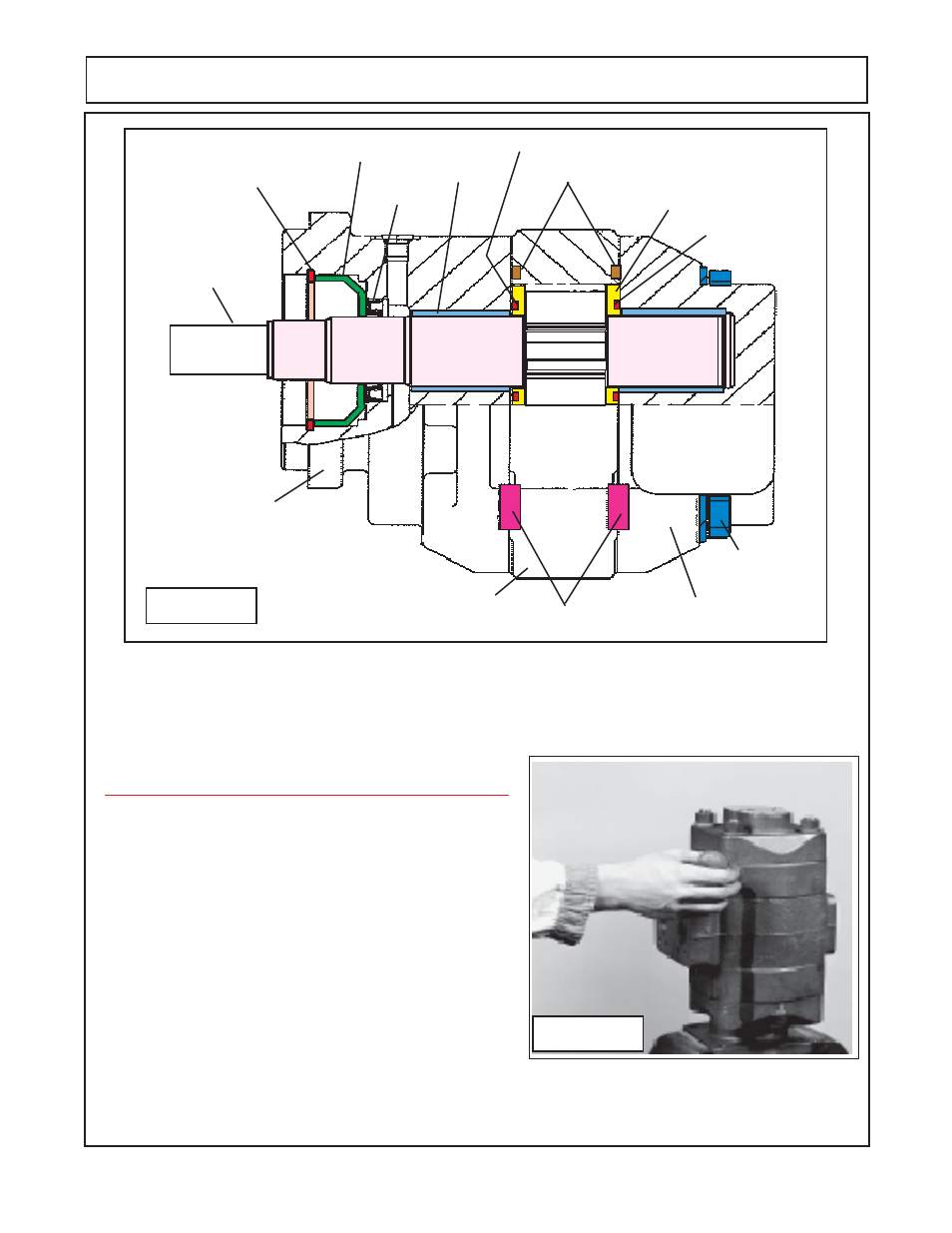

Motor service & repair, Figure 16, Figure 15 – Alamo HYDRO 15 User Manual

Page 50: Motor dis-assembly caution

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 3 - 12

Figure 16

12345678901234567

12345678901234567

12345678901234567

12345678901234567

12345678901234567

12345678901234567

12345678901234567

12345678901234567

12345678901234567

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

Shaft &

Gear Set

(Drive gear

& Driven

Gear)

Snap Ring

Seal Retainer Cup

Input Seal

Bushing (2)

Channel Seal (2)

SquareHousing Seal

Channel Seal

(2)

Thrust Plate (2)

Shaft End Cover

Dowel Pins (4)

Retaining Bolt &

Washers (4)

Port End Cover

Gear Housing

Figure 15

MOTOR SERVICE & REPAIR

Shown above (figure 15) is a general breakdown of the motor components, The motors are basicaly the

same in design and replace componetn procedure. Each motor will asemble different as some of the compo-

nents are different. Refer back to figure 15 for later motor assembly information

Motor Dis-Assembly CAUTION! :

Important information - read before dis-assembly:

1.

If prying off sections becomes necessary, take

extreme care not to mar or damage machined sur-

faces. Excessive force while prying can result in

mis-alignment and seriously damage parts.

2.

If sections of motor are difficult to come apart

during dis-assembly, tap gently with a soft hammer

(never use an iron hammer).

3.

Gears are closely matched, therefore they must

be kept together as sets when removed from the

pump. Handle gears with care to avoid damage to

journals or teeth. Avoid touching gear journals.

4.

Never hammer bushing into bores: always use

an arbor press.