Pump service & repair, Figure 30 figure 31, Figure 28 figure 29 – Alamo HYDRO 15 User Manual

Page 34

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 2 - 18

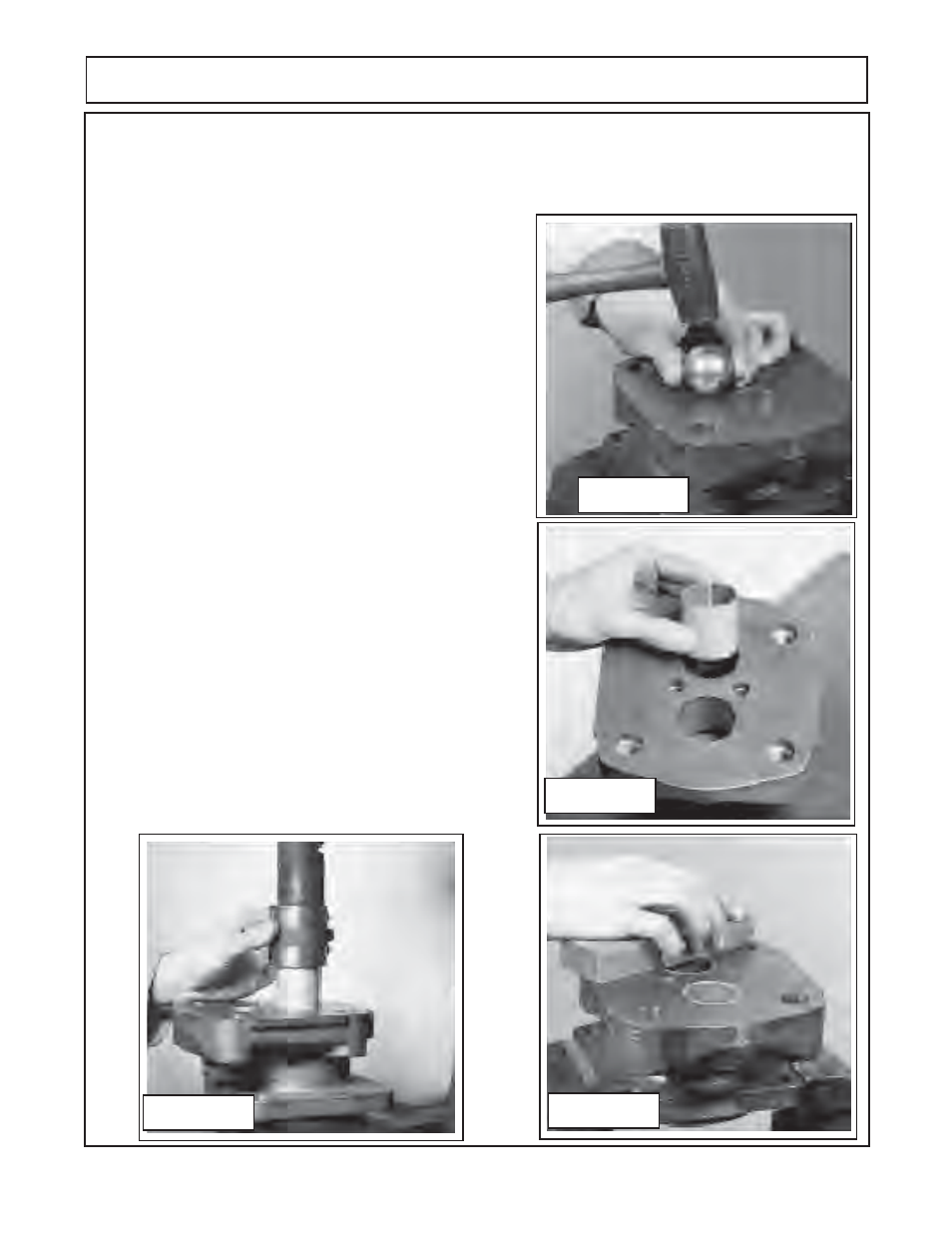

Figure 30

Figure 31

7.

Repeat steps 1 and 2 after busings are installed

(See

steps 1 & 2).

Just as earlier if the stone is used parts it is used

on

MUST

be washed and dried . Make certain bushings are

flush with castings and there are NO burrs on the top ID of

bushings.

(figure 31).

8.

Check to make certain that the dowel pins are in place in

any new castings and that the location corresponds with the

mating casting. Before inserting any dowel pins check to make

certain holes are clean, the top of the holes do not have burrs.

To insert dowels hold the dowel in alignment with the hole.

Gently start the pin into the hole straight, tap lightly with a soft

hammer until dowel is seated into hole.

(figure 32).

Note as

shown, dowel pins have holes in the center, this is for the

studs to go through.

9.

Remove the shaft end cover from the vice and turn it over

180° and re-insert it into the vise with the splined side up (figure

34).

Before inserting the new lip seal

(figure 10 item 3)

into the

shaft end cover Coat the outer edge of the lip seal with

Permatex Aviation Form-A- Gasket™ No. 3 non-hardening

sealant or equivalent. With the metal side of the seal up, press

it into the mounting flange side of the shaft end cover with an

arbor press and bar

(see recommended tools list)

. Be careful

not to damage the lip seal. Press the lip seal in until flush with

the recess, wipe off excess sealant.

10.

Install the outboard bearing

(figure 10 item 2)

, guide the

bearing into the recess in the shaft end cover. This is a light

press fit and can be pressed in with the arbor press or it can

be lightly tapped into the bore.

DO NOT

use excessive force

to insert bearing, if it will not go with light

(continued next page)

PUMP SERVICE & REPAIR

Figure 28

Figure 29

6.

Bushings should be pressed into the bores one at a time, Use the special installation tool

(figure 5 Tools

recommended list)

and an arbor pres. Be sure that the groove (or seam) are positioned as stated in

step 5

previously

. Be sure to support casting so they are square and level to the arbor press and the bushings are

straight before attempting to press them in. The bushing must be pressed into the bores flush with the casting

face

(figure 30).