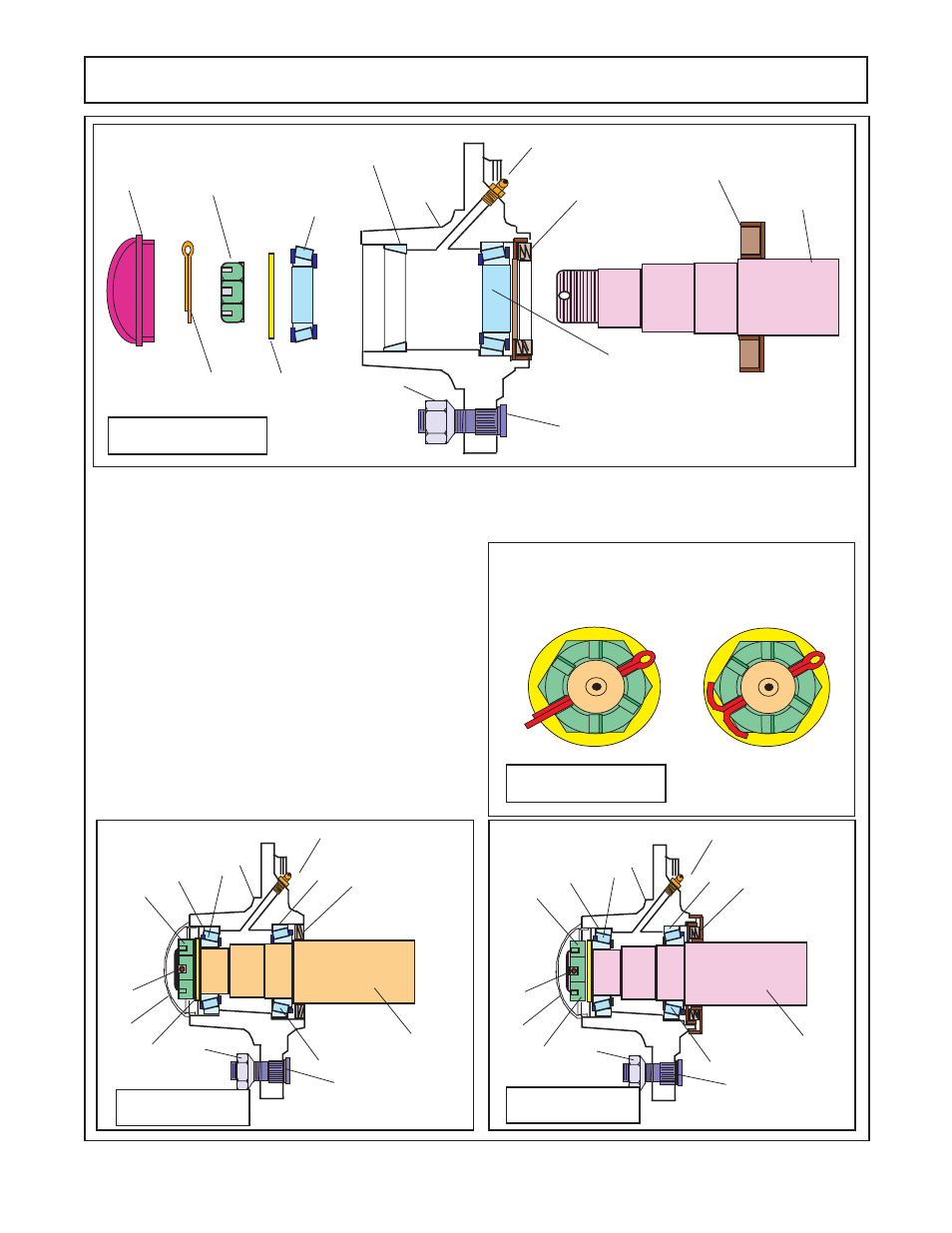

Tire - wheel - hub service & repair, Figure 10a, Figure 13 – Alamo HYDRO 15 User Manual

Page 131: Figure 12, Figure 11

Section 8 - 7

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Tire - Wheel - Hub Service & Repair

Seal Protector

Axle Spindle

Three Piece

Seal

Grease Fitting

Inner Bearing

Cone & Cup

Hub

Outer Bearing

Cone

Outer Bearing Cup

Lug Nut

(Coned)

Wheel Stud

Spindle

Washer

Bearing

Adjusting

Nut

Cotter

Pin

Dust

Cap

FIGURE 10A

123

123

123

123

123

123

123

123

123

123

123

123

123

123

Whl Hub Asy

(3 piece Seal)

9.

Install cotter pin

(item 3),

Push Cotter Pin into hole until the head (loop in cotter pin) is no higher that the

washer

(figure 11).

Bend the cotter pin outward

(figure 11)

, it may require the ends of the cotter pin to be cut,

if so use a pair of diagonal cutters. DO NOT Cut cotter pin so short the ends can not be bent over

(figure 11).

Make certain the cotter pin doesn't stick outward so

far that it rubs the dust cap that is to be installed.

Whl Hub Asy - 3 piece Seal

FIGURE 13

8

1

2

3

4

5

6

7

9

10

11

12

13

14

Whl Hub Asy - 1 piece Seal

FIGURE 12

8

1

2

3

4

5

6

7

9

10

11

12

13

14

Cotter Pin

Installed

Cotter Pin

Installed & Bent

FIGURE 11

10.

Install dust cap

(item 2).

The Hub can be

greased now if wanted, Pump grease in through

fitting until grease comes out the front between

rollers of outer bearing cone. Carefully drive dust

cap

(item 2)

onto up aligning the dust cap rim with

the edge of hub. Carefully drive the dust cap onto

hub until it is seated into the recess of the hub

(figure 12 & 13)

. Caution dust cap must be installed

squarely and driven on until they are fully seated.

When Assembled look at figure 12 & 13, this is

what it should look like.