Spindle assembly - service & repair, Figure 26 – Alamo HYDRO 15 User Manual

Page 71

Section 4 - 7

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

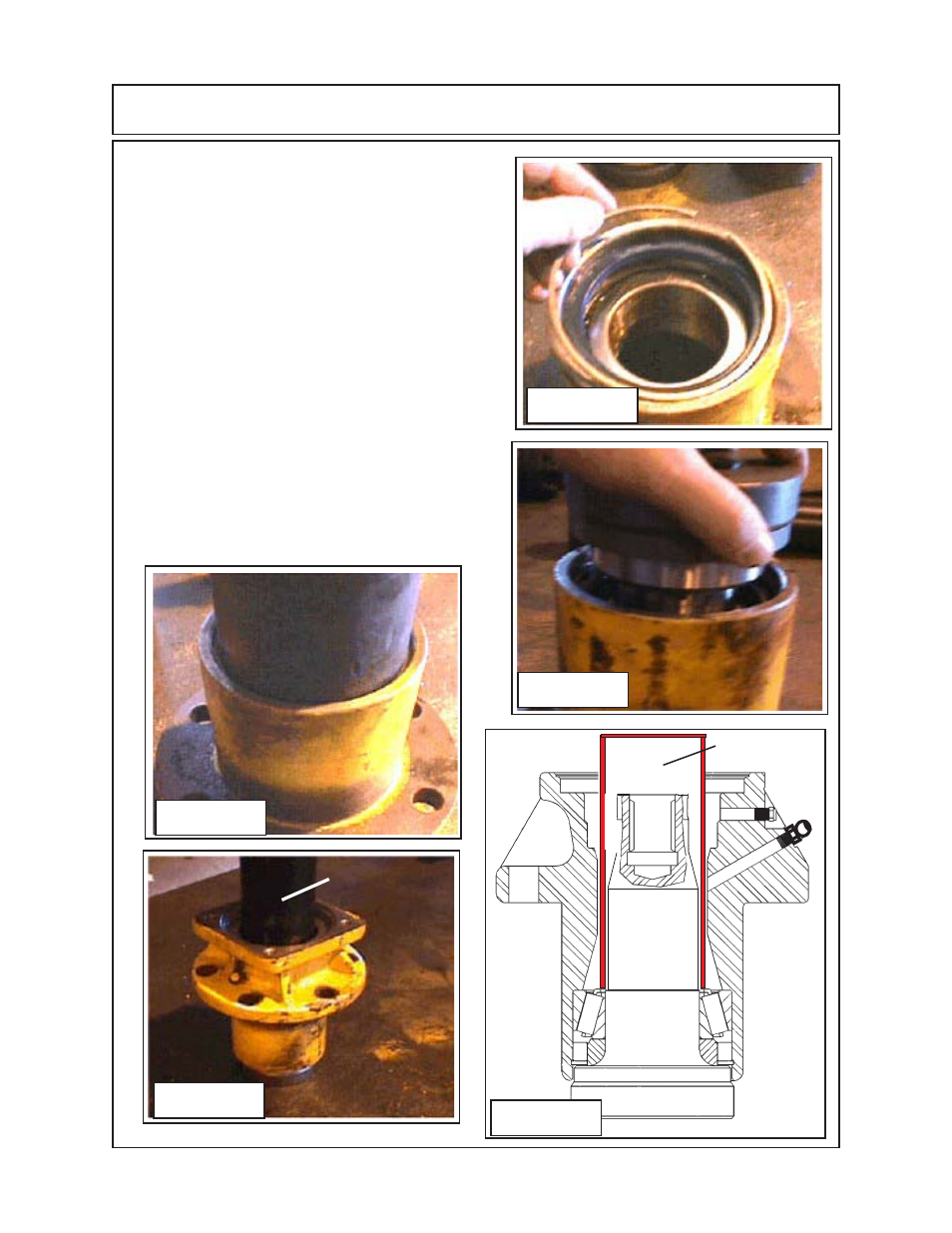

Figure 22

Figure 23

Figure 24

Figure 25

SPINDLE ASSEMBLY - SERVICE & REPAIR

5.

Place the spindle shaft with the bearing ring

installed into the spindle housing. Turn the assembly

over so that the housing is sitting upright and the

spindle shaft is supporting the housing.

(figure 24 &

25)

. Make certain to support the spindle housing to

keep it straight up as the lower bearing ring is being

inserted into the seal as the lower bearing is being

driven down onto the shaft

(figure 26).

Use the 2-3/4”

16 gauge tubing to drive the lower bearing down onto

the bearing ring

(figure 26).

.

MAKE CERTAIN THAT

THE BEARING IS FULLY SEATED ONTO THE

SPINDLE

. If the bearing ring is not seated, or if

the bearing is not properly seated against the

bearing ring, the assembly will lose bearing

preload and rapidly fail

(figure 25).

6.

Remove the 2-3/4" 16 gauge pipe from the spindle

housing. Check to make certain the shaft, bearing ring

and lower bearing are seated properly. Install the

upper bearing cup using proper size driver. Make

certain the bearing cup is seated completely into the

spindle housing

(figure 26 & 27).

2-3/4” 16 gauge

tubing 8” long

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

Figure 26

2-3/4” 16 gauge

tubing 8” long