Motor service & repair, Wear tolerance for pump & motor – Alamo HYDRO 15 User Manual

Page 54

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 3 - 16

MOTOR SERVICE & REPAIR

Wear Tolerance for Pump & Motor:

This is suggested Wear Tolerance to Keep Assemblies operating as efficient as

possible, Not Complete failure rate. Your Pumps and/or motors may not be exact same as

discussed here.

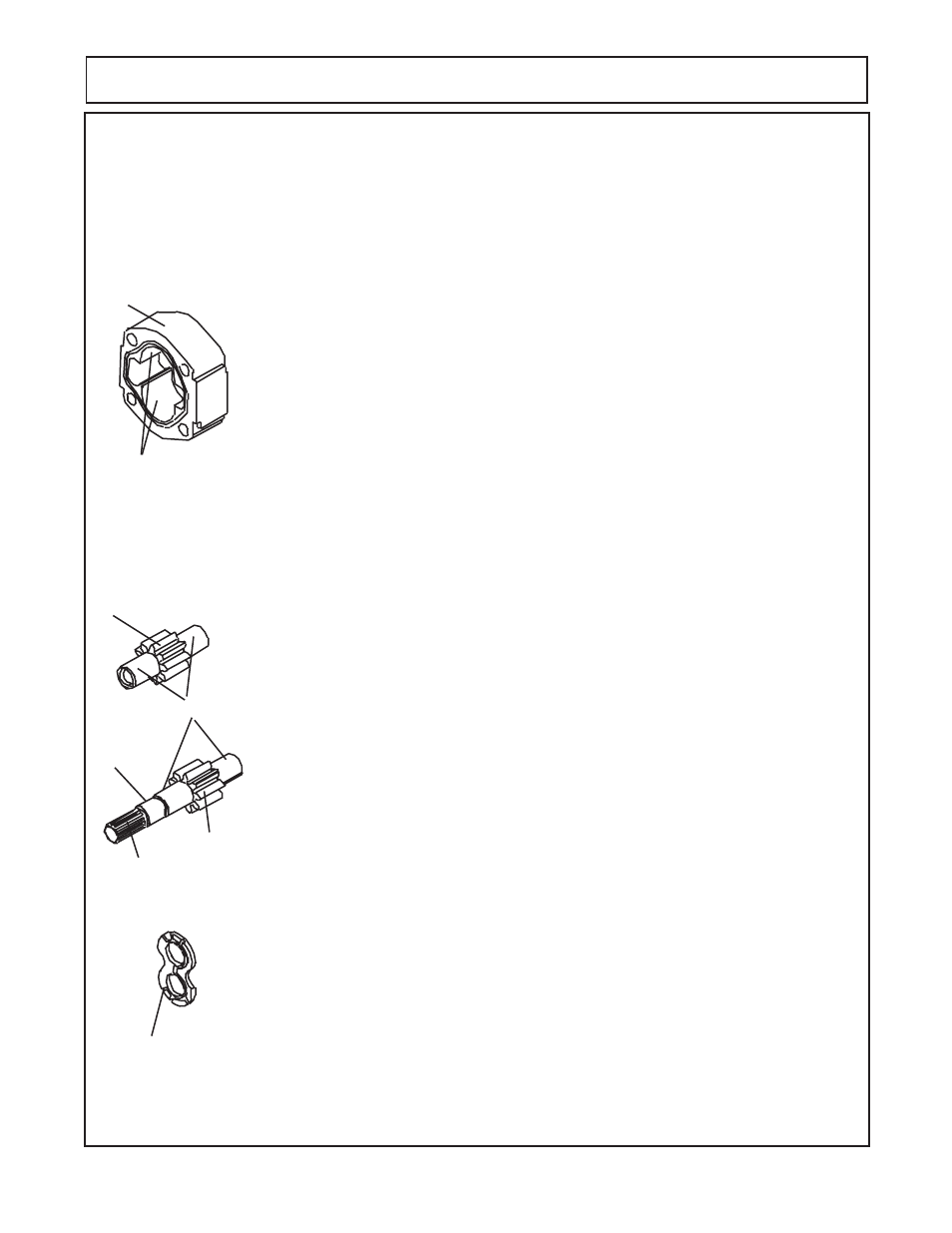

Gear Housing: Gear type Pump and Motor

Wear in excess of .007" cut-out necessitates replacement of the Gear

Housing. Place a straight edge across the Bore in the cut out area. If you can slip

a .007" feeler gage under the straight edge in the cutout area. Replace the Gear

Housing.

Pressure pushes the Gears against the Housing on the Low-Pressure side.

As the Hubs and Bushings wear, the cutout becomes more pronounced.

Excessive cutout wear in short period of time indicates excessive pressure or Oil

contamination. If the relief Valve Settings are within prescribed limits check for

shock pressures or tampering. Withdraw Oil Samples and check it and tank for

dirt. Where cut-out is moderate, 0.007" or less, gear housing is in good enough

condition and may be reused, understand if you are at 0.007" you are at the upper

limits and will not be at peak performance. A pump should always produce at least

85% efficiency (Example: if your Pump is rated at 37 GPM it should produce at

least 32 GPM).

Gears:

Any scoring on Gear Hubs necessitates Replacement. Scoring, Grooving or

Burring of Outside diameter of Teeth requires replacement. Nicking, Grooving or

Fretting of Teeth surfaces also necessitates replacement.

Drive Shaft:

(with Built on Gear)

If Gear Teeth and Gear Hubs are OK, Inspect Splines on input end (OD) of

Shaft and the Splines (ID) Output) Coupler End (Tandem Pump) for condition and

Wear.

Inspect Wear or damage to Seal Wear Area. If damage at Seal are check for

contamination. Note: Some Pumps and/or Motors may have Keyway or Splines.

Either will have to be inspected for condition. If Damage in any of these area the

Shaft / Gear will have to be replaced.

Thrust Plate:

The Thrust Plate Seals the Gear Section at the sides of the Gears. Wear will

allow internal slippage, which is Oil bypassing within the pump. The Pump and

Motor Thrust Plates are different even though they may look very similar. They are

built different. They will not interchange.

A Maximum of 0.002" wear is allowable. Replace Thrust Plates if they are

scored, eroded or pitted. Wear can be checked usually by comparing thickness

at outer edges with thickness at Gear contact area.

1. Check center of Thrust Plates where the Gears mesh. Erosion here indicates

Oil contamination.

2. Pitted Thrust Plates indicate cavitation or Oil aeration.

3. Discolored Thrust Plates indicate overheating, probably insufficient Oil.

Gear Teeth

Gear Hubs

Seal

Area

Splines

Gear Teeth

Thrust Plate

Cut-Out Area

Gear Wear Area

Gear Housing