Motor service & repair, Motor cleaning & removal, Figure 8 motor information – Alamo HYDRO 15 User Manual

Page 46: Figure 9

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 3 - 8

MOTOR SERVICE & REPAIR

Motor Cleaning & Removal:

1.

Clean Motor, Hoses and all connections before discon-

necting any components from the motors. This will keep con-

tamination from getting into system, (in this illustration the

mower is new, clean and un-used). Some type of drain pan

will be required to catch the oil that will drain out when hoses

are dis-connected. The hoses will need to be capped (plugged)

after being disconnected. If cap is not leak proof then hoses

must remain elevated above hydraulic tank to prevent oil leak

age from hose fittings.

The Center Motor and the Wing motors are built different

and will look different. The easiest way to ID which is which is

by the four bolts that hold the motor together. On center motor

the bolts are in the open as shown

(figure 9)

, on the wing motors

they are down inside a machined hole on the Port End Cover

(figure 10, 11 & 12).

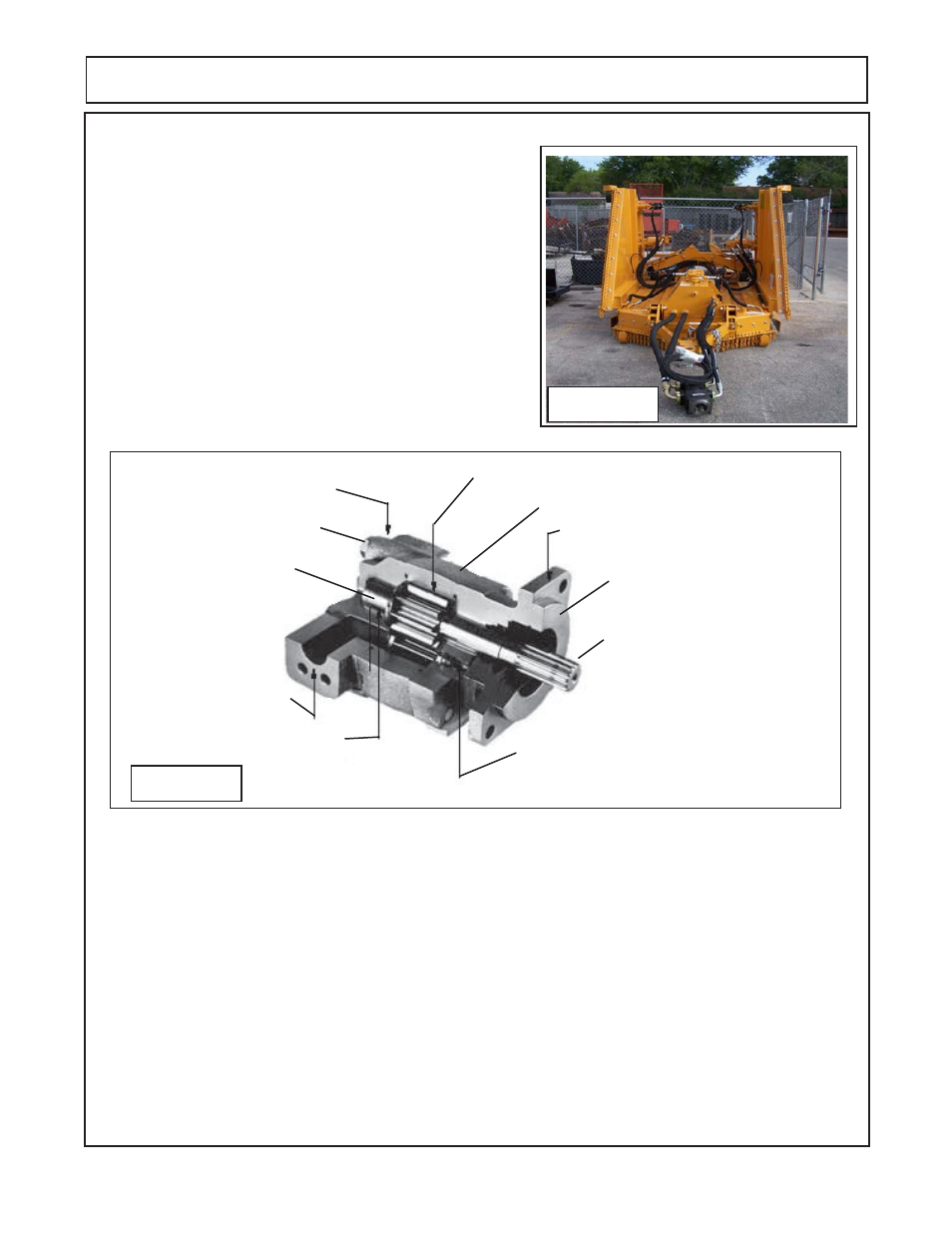

Figure 8

Motor Information:

Center.

Center motor is very different from the wing motors in design. The Housings are more square than the wings.

The manifold blocks are different, the center is thinner and will not use the solenoids that the wings do. The

four assembly bolts on the center motor are visible under manifold block.

(figure 10)

The center motor is

assembled to turn in a CW rotation which should be marked on the motor mounting flange from the factory.

The rotation is determined by standing on the deck behind the motor facing forward. Make certain which motor

is being serviced, Most parts will not interchange between the cent and wing motors.

RH Wing:

The RH wing motor is basically the same as the LH wing motor with the exception of the Port end cap is

installed different

(figure 11)

. The wing motor the four assembly bolts are in a machined hole under the manifold

block. The manifold block will need to be removed to see them. The RH Wing motor is assembled to turn in

CW rotation which should be marked on the motor mounting flange from the factory. The rotation is determined

by standing on the deck behind the motor facing forward. On the wing motor the fourassembly bolts are

in a machined hole under the manifold block. Make certain which motor is being serviced,

Iron Housing

Gear Set (Matched Set)

4 Bolt Mounting Flange

Port End Cover

Split Flange

2 on center motor

1 on each wing motor

High Temperature Seals

Low Friction Bushing Casting

Splined Input Shaft

Bolt & Lockwashers

Drive Gear w/Shaft &

Driven Gear

Figure 9

CENTER SECTION MOTOR SHOWN

Gear Housing

Shaft End Cover