Pump service & repair, Pump assembly caution, Figure 24 – Alamo HYDRO 15 User Manual

Page 32: Thrust plate caution! : (figure 24)

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 2 - 16

Pump Assembly CAUTION! :

Important information - read before assembly:

1.

All sections have been cleaned and inspected, take extreme care not to allow the marring or

damage to machined surfaces to occur. Make certain all components are laid out so as not to

damage the machined surfaces.

2.

Make certain any replacement parts have been compared to the old parts to make certain they

are correct.

3.

Gears are closely matched, there fore they must be kept together as sets when removed from

the pump. Handle gears with care to avoid damage to journals or teeth. Avoid touching gear journals.

DO NOT mix new and old gears when reassembling pump.

4.

Never hammer bushing into bores: always use an arbor press, Hammering will damage

bushings and possibly the bores in the housing.

5.

(NOTE illustrations shown here are for a single pump, the tandem

pump is longer with more

sections, the disassembly will be basically the same with the exception tandem pump has two

pump section instead of one. See figure 9 & 10 for reference to components)

.

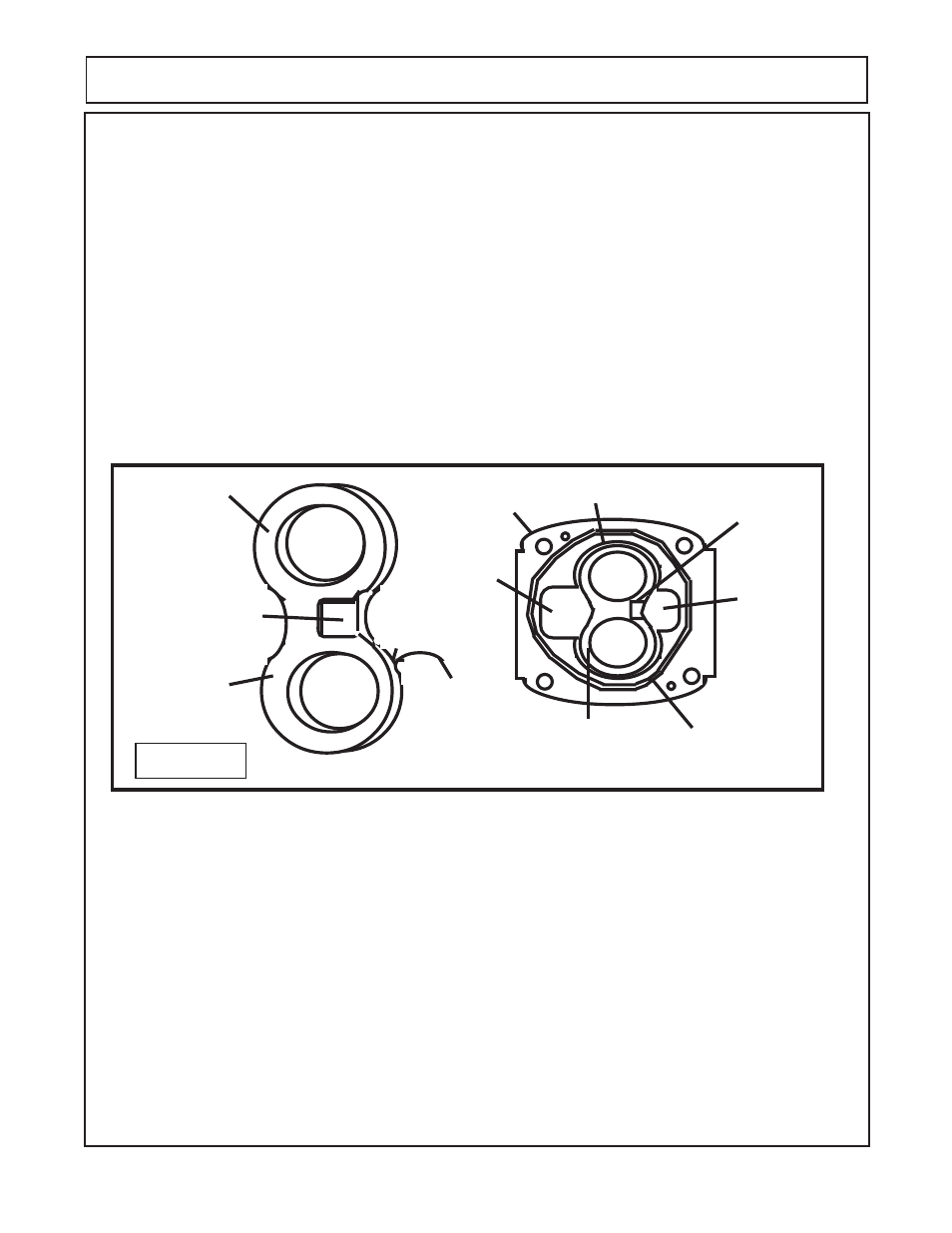

Gear Housing

Gear Bore

Gasket Seal

Outlet

(pressure)

Core

Opening

Relief Groove (High

Pressure)

Thrust Plate

Gear Side

(Smooth Side)

Channel

Seal Side

(Grooved Side)

Inlet

(Suction)

Core

Opening

Relief Groove (High

Pressure)

Thrust Plate

Installed in Gear

Housing

Figure 24

PUMP SERVICE & REPAIR

Thrust Plate CAUTION! : (Figure 24)

Important information - read before assembly:

1.

Thrust Plates must be in good condition, no scratches or excessive worn places on either side

of plate.

2.

Thrust plates must be installed correctly, The thrust plate has two surfaces, one surface has

a groove for the channel seal and the other surface is smooth with a relief groove (notch) in it.

3.

Thrust plate smooth surface with relief notch will always face the gears, the groove side for the

channel seal side will always face the gear bearing journal bushings never the gears as the gear

would destroy the channel seal.

4.

The relief groove will face the High Pressure side or Outlet Side of the gear housing. This is

determined by the port (bearing carrier or port end cap) port size. The Inlet (suction Side port will

have a bigger opening than the pressure side.

5.

These thrust plates are very important to the way they are installed. If they are installed wrong,

the pump will not function properly and other components could be damaged if operated with them

wrong.