Motor service & repair, Wing motor electric switches, Figure 48 – Alamo HYDRO 15 User Manual

Page 62

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 3 - 24

MOTOR SERVICE & REPAIR

Recommended Start-Up Procedure For New Or Rebuilt Pump & Motor:

(Important Steps 26 through 30)

1.

Before installing a new or rebuilt pump or motor, back off the main relief valves until the spring tension on

the adjusting screw is relieved

(See Specification section for relief valve settings).

This will avoid the possibility

of immediate damage to the replacement pump in the event the relief valve has been set to high.

2.

Before connecting any lines (hoses) to the pump fill all the ports with clean oil to provide initial lubrication

on start up, fill the suction hoses with oil. This is particularly important if the pump is located above the reservoir.

Use thread sealant on all fittings and hose threads. DO NOT USE TEFLON TAPE.

3.

Make certain the oil reservoir is full of clean oil. Test oil before running a replacement pump. Contaminated

oil will damage a replacement pump even oil ran a minute or so. Review the type of failure that had occurred

and investigate any damage that may have been caused due to that failure.

DO NOT run the replacement pump

if the cause of the failure has not been corrected.

Any oil added to or to fill reservoir must be ran through a

100 micron screen before going into tank. See the tank fill section for available equipment for this purpose.

Never

run hot oil through a cold pump or motor, the hot oil will cause damage to the cold components

. Gradually warm

components by turning pump on then off, on then of until temperature is equalized.

4.

After connecting the lines (hoses) and mounting the replacement pump, operate the pump at least two

minutes at no load and at low RPM (400 rpm). During this break-in period, the mower should run free (no load)

and not develope an excessive amount of heat. If the unit operates properly, speed and pressure can then be

increased tonormal operating settings (See Specification Section).

5.

Reset the main relief if needed to its proper setting while the pump is running at maximum operating engine

(motor) speed for the PTO rating. (See Specification Section)

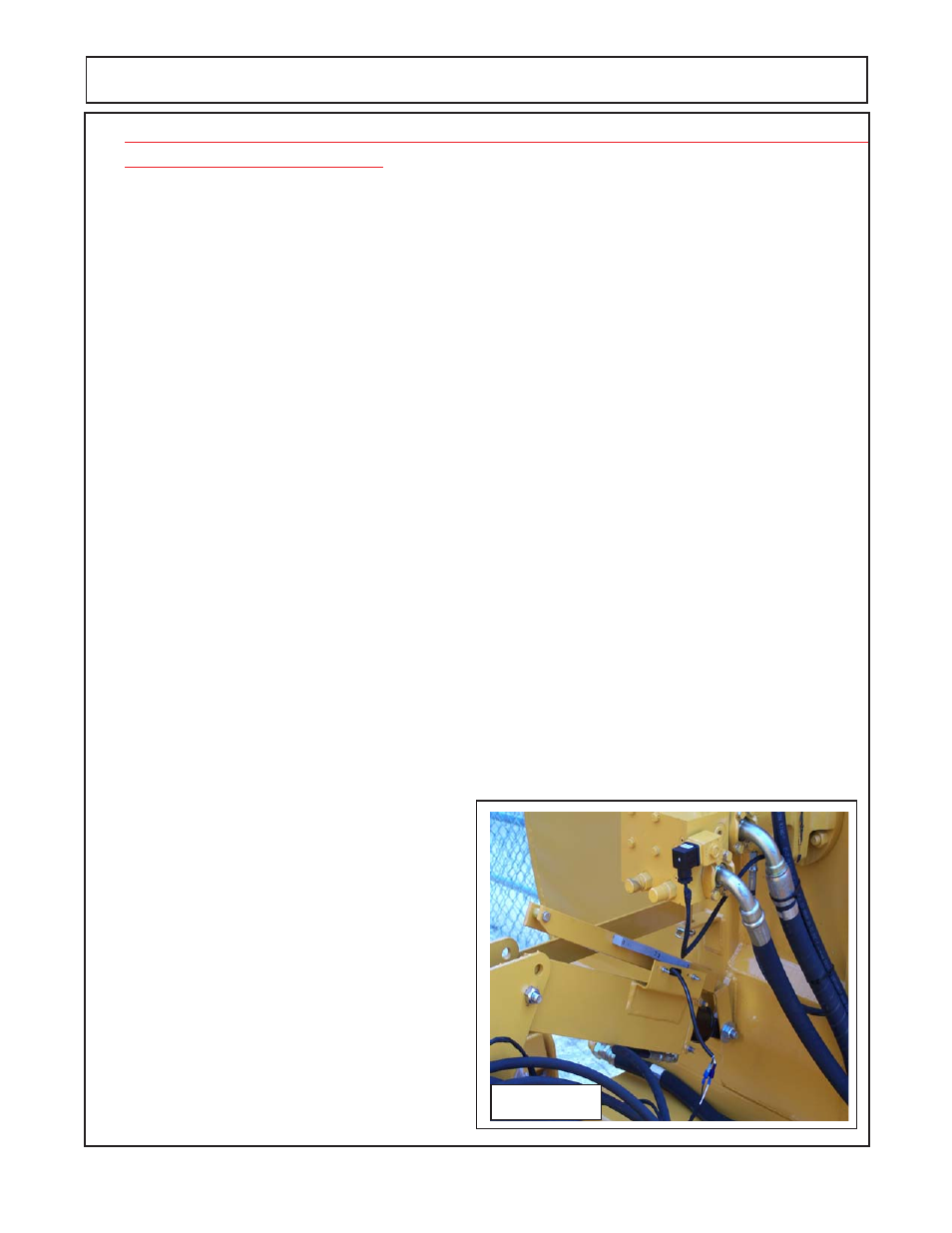

Wing Motor Electric Switches:

1

Wing Motors are equipped with electrical solenoids located it the motor manifold blocks, these are designed

to function with magnetic switched on brackets that are connected to the wing lift cylinders. The wings are

designed through these solenoid switches to turn the motors off when the wing is raised to a set angle. The

motors are also equipped with hydraulic brakes that are designed to speed the time it takes to stop the motor,

these also work through the motor manifold block.

(figure 48 LH Wing Shown)

2.

The Center Section Motor is controlled by engaging or dis-engaging the tractor PTO.

3.

Any time motors are being started the tractor

RPM should be reduced during start-up of motors.

Figure 48

4.

Cylinder Switch Brackets bolt to cylinder with a

U-Bolt and the cylinder mounting bolts

(figure 49 RH

Wing Shown)

. The switches and magnetic pickups

will bolt to the cylinder bracket. The Switch will have

two wires a white wire and a black wire. The wires will

have a female spade connector on the black wire

which will connect to the black/white wire on the wire

harness

(figure 50).

The switch white wire will have a

male spade connector which will connect to the white

wire of the wire harness

(figure 50).

5.

The leads to the tractor are to be connected with

the

positive 12 volt negative ground source

that is only

activated when the tractors ignition key is on. If it is

connected to a constant power source it will run the

Continued Next Page