Blade & blade carrier service & repair, Blade & blade carriers service & repair, Figure 3 figure 2 – Alamo HYDRO 15 User Manual

Page 134: Figure 1, Pan carrier bar carrier

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 9 - 2

Blade & Blade Carriers Service & Repair

1.

Make certain the mower and tractor are secured in a safe and proper parked position, hydraulic (axle

and wings) lowered or secured by the transport bars. Make certain that tractor is safely parked according to

tractor manufacturers recommendations. Tractor should be secured (or dis-abled) in a way that it cannot be

started unless the serviceing technician is ready for it to be started.

Never get under any equipment unless

it is secured and supported by sufficent jackstands, DO NOT depend on hydraulics or brackets to support

equipment if you are going to be under it, this is important!

See the Operators Manual for recommended

Maintance schedules and recommendations.

2.

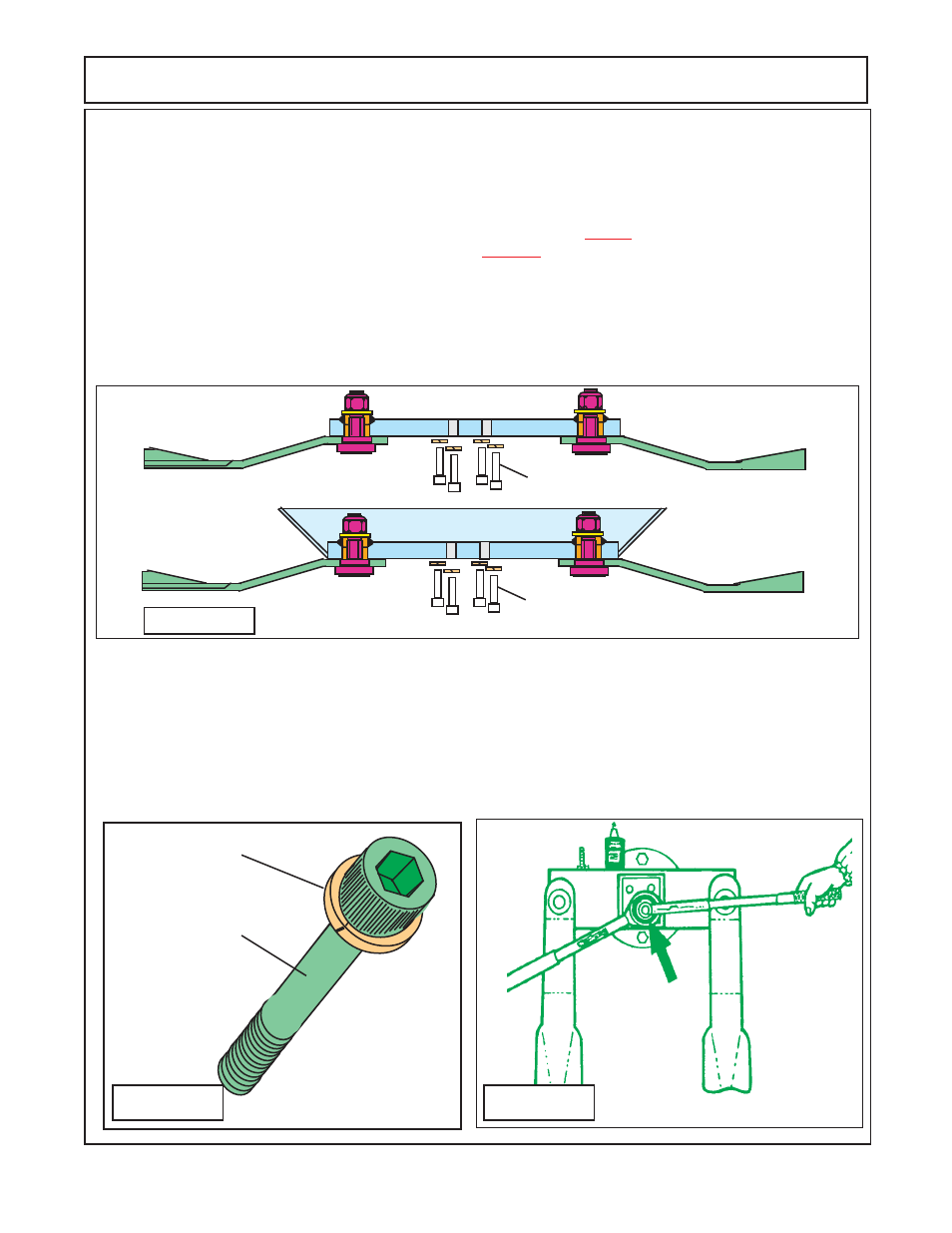

There are blade carriers option of bar carrier or pan carrier

(figure 1)

. The basic mounting design of the

connecting blade carriers to the spindles are the same, and will follow the same directions even with the fact

some of the components are different.

Blade & Blade Carrier Service & Repair

3.

Blade Carrier Spindle Mounting Bolts, These bolts hold the blade bar onto the spindle and must be

torqued when being installed. These are high strength Allen head bolts

(figure 2)

and should be replaced with

the proper length of bolt, never install a longer bolt than was removed. If longer bolts are installed damage will

occur . Always replace the lockwasher

(figure 2)

when reinstalling the bolts, it is not recommended to use

the lockwashers twice. When changing or installing a blade bar, place one drop of Loctite on threads of each

bolt before installing it in place. Tighten the bolts diagonally

(in an X pattern)

to assure that the blade bar

pulls up evenly.

Torque the bolts to 400 ft./lbs.

(figure 3)

in increments, example 300 ft lbs then 350 ft lbs, then the last

to 400 ft lbs. This will help to make certain the blade carrier is pulled up evenly to the spindle..

Figure 3

Figure 2

Allen Head Bolt

Lockwasher

Figure 1

Carrier Retaining Bolts & Lockwashers

123

123

123

12

12

12

12

12

123

123

123

12

12

12

12

12

123

123

12

12

12

12

12

12

123

123

123

12

12

12

12

12

Pan Carrier

Bar Carrier

Carrier Retaining Bolts & Lockwashers

123

123

12

12

12

12

12

12

123

123

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12