Wing lift & fold cylinder repair – Alamo HYDRO 15 User Manual

Page 86

HYDRO 15 (Service Manual) 10/06

© 2006

Alamo Industrial

Section 5 - 12

5.

Install cylinder head seal

(figure 8 step 1

item 4A)

. Turn the cylinder head over as shown

(figure 9 step 1). Coat the back-up ring with

light coat of oil and slide it down over cylinder

head, NOTE: some back rings have a round

depression in one side, this side will be mounted

up so the round O-ring seal will fit in the

depression. Slide the back-up ring down over

cylinder head until it is seated into the groove

(figure 9 step 2 item 4A)

. Coat the O-Ring

(figure 9 item 4A)

with oil and slide it down onto

the cylinder head until it is seated into the

groove

(Figure 9 step 2 item 4A)

. The Cylinder

head is complete, set it aside for now.

6.

Install the Cylinder Head

(figure 10 item 4)

onto the cylinder rod. Coat the cylinder rod with

light coat ofoil and slide the cylinder head onto

it. It should slide on with minimum effort but it

must be slid on square and straight,

DO NOT

use a hammer to force the cylinder head onto

cylinder rod if it will not slide on by hand force

check the components something is wrong

and forcing it could damage head and seals.

WING LIFT & FOLD CYLINDER REPAIR

3.

Install the cylinder rod seal into the cylinder head

(figure 7 item 4C)

. Install the rod seal first

coating the seal with petroleum jelly (vaselene) on the OD of seal. Slide the seal into the ID of the

of the cylinder head

(figure 7 step 1).

Using a nylon (plastic) rod press down on seal, light taps with

small hammer will be ok providing you watch the bottom of the seal and make certain it is started

in the seal groove and not being driven on through cutting seal

(Figure 7 step 2).

drive seal in until

it is seated into the groove (Figure 7 step 3)

.

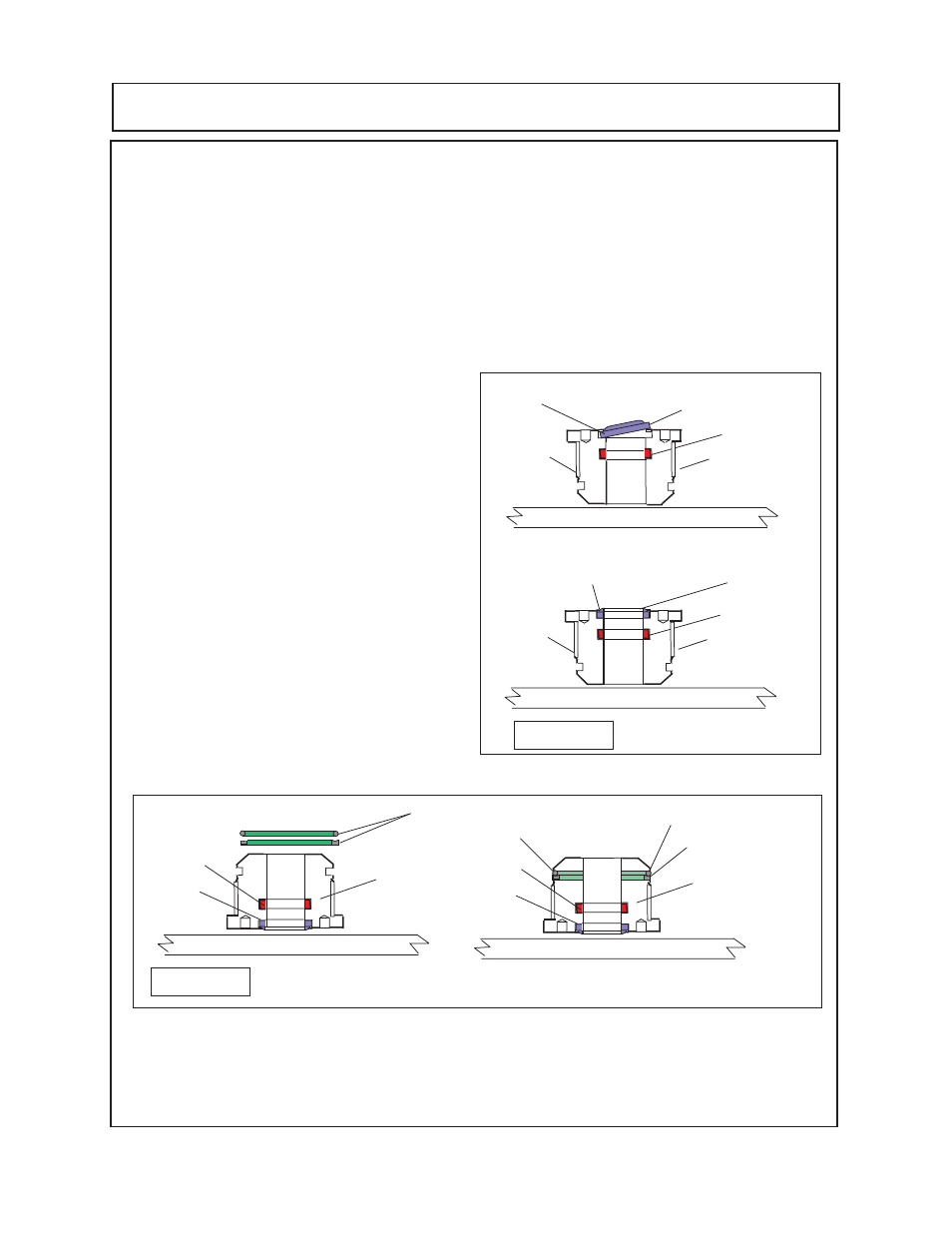

4.

Install the snap in cylinder rod wiper seal into the cylinder head

(figure 8 item 4B)

. Turn the

cylinder head over where the groove for the wiper seal is up-ward. Install the wiper seal first coating

the seal with petroleum jelly (vaselene) on the OD of seal. Slide the seal into the ID of the of the

cylinder head

(figure 8 step 1).

Press down and inward on seal until seal is seated in groove

(Figure

8 step 2).

Check seal to make certain it was nut cut during installation.

Cyl Head

4

4C

Clean Work Bench

12

12

12

12

12

12

12

12

12

12

12

12

12

12

Push Down & Inward Here

Step 1

Cyl Head

4

4C

Clean Work Bench

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Step 2

Push Down & Inward until

Seal is seated in groove

4B

4B

Figure 8

7.

Installing the Piston on the cylinder rod (figure 10 item 6) will require a press,

DO NOT

try to

press piston onto cylinder rod with the piston nut.

Use Locktite 271 or equivalent

when pressing

piston onto cylinder rod. Make certain piston and rod are in alignment when pressing piston, make

certain piston and rod are protected from damage.

Figure 9

Step 1

Cyl Head

4

4C

Clean Work Bench

4B

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4A

Cyl Head

4

4C

Clean Work Bench

4B

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4A

Step 2

Back-Up Seal

O-Ring Seal