Motor service & repair – Alamo HYDRO 15 User Manual

Page 58

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 3 - 20

Figure 37

Figure 34

Figure 35

Figure 36

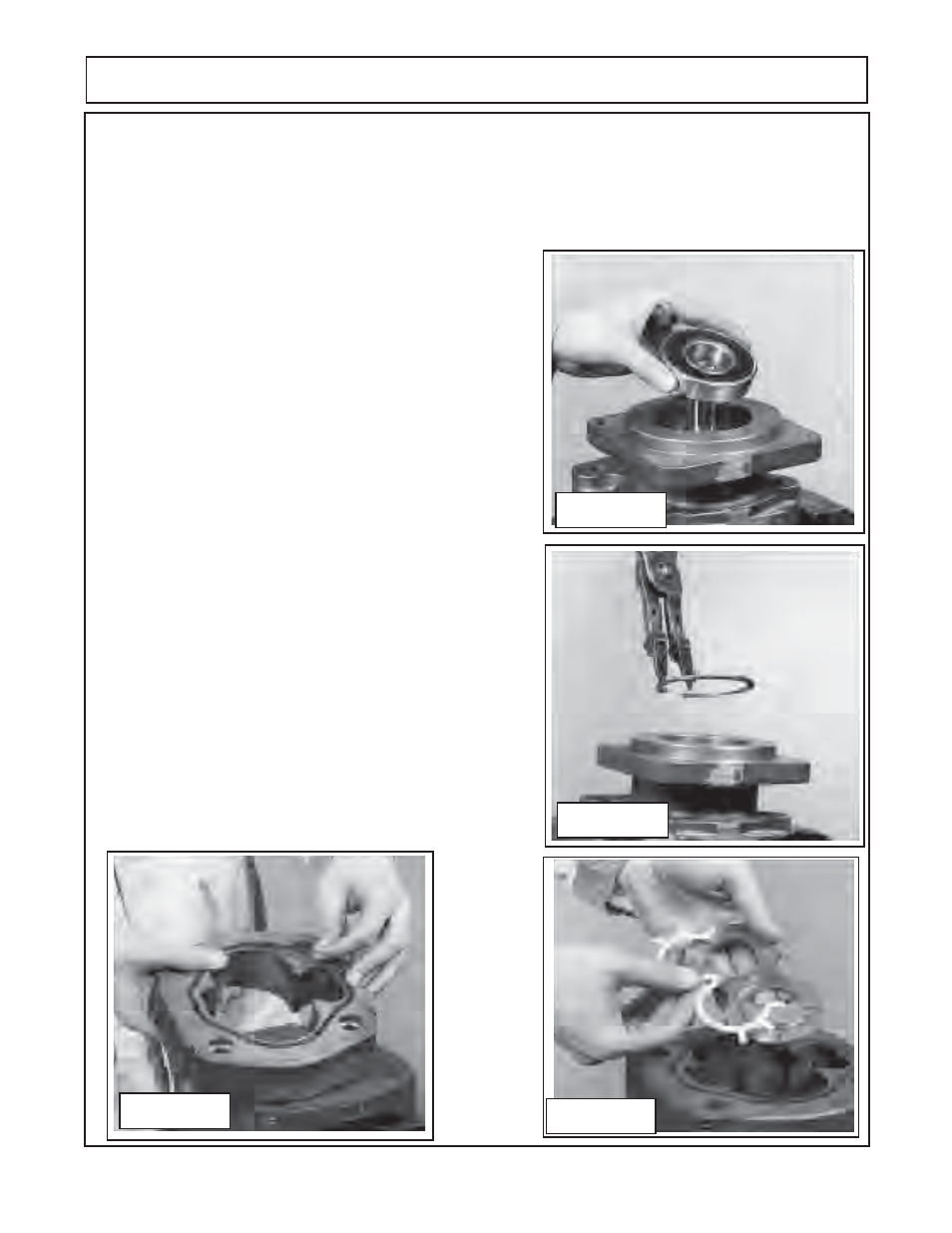

MOTOR SERVICE & REPAIR

12.

Assemble the channel seals

(figure 37 & 38)

into the

grooves in the thrust plates

,

with the flat side of the seal

facing away from the thrust plates as shown

(figure 37 &

38).

IMPORTANT NOTE:

Channel seals will always be on

side of thrust plate away from gears, only the smooth side

of thrust plates are against gears. The channel Seals will

be all around gear shaft journal opening on motors.

13.

Gently slip the thrust plate

(figure 39)

into the gear housing

and into place on the shaft end cover

(figure 39).

The channel

seal from

step 13

should face the shaft end cover. The relief

grooves in the thrust plate should face the outlet gears

figure

39).

14.

Coat the driven gear journal with light coat of oil, Slide the

driven gear

(figure 40)

through the housing and into the bushing

in the shaft end cover

(figure 40)

Coat the drive gear

splined

shaft end with light coat of grease, insert shaft into the

special steel sleeve

(figure 7 recommended tools list)

. Lightly

seal. Remove steel sleeve, squirt clean oil over gears

(figure

40)

.

Note

purpose of sleeve is to prevent splines on the shaft

from damaging double lip seal. Coat the steel sleeve with

grease. Place the lightly greased drive gear shaft inside the

sleeve and slide both through shaft end cover with a twisting

motion until the integral gear rest against thrust plate. Avoid

damaging double lip seal. Remove steel sleeve, squirt clean

oil over gears

(figure 40)

.

Note

purpose of sleeve is to prevent

splines on the shaft from damaging double lip seal.

10.

Using the snap ring pliers as shown. Install the snap ring into the flange side of the shaft end cover

(figure

35).

Lightly tap the snap ring with a small punch and hammer to make certain it is seated into the snap ring

groove of the shaft end cover.

11

Remove the shaft end cover

(figure 36)

from the vice and turn it over 180° and re-insert it into the vise with

the splined side down and re-insert it into the vise. Grease the new Gasket Seals

(figure 15)

and insert

it in both sides of all gear housing. Position the gear housing

(figure 36)

onto the shaft end housing

(figure

35)

aligning it with the holes for the dowel pins.

Tap it with a soft hammer until it rest tightly against the

shaft end cover.

Be careful not to pinch the seal gasket

(figure 36).