Speed increaser service & repair, Figure 11 – Alamo HYDRO 15 User Manual

Page 122

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 7 - 12

Speed Increaser Service & Repair

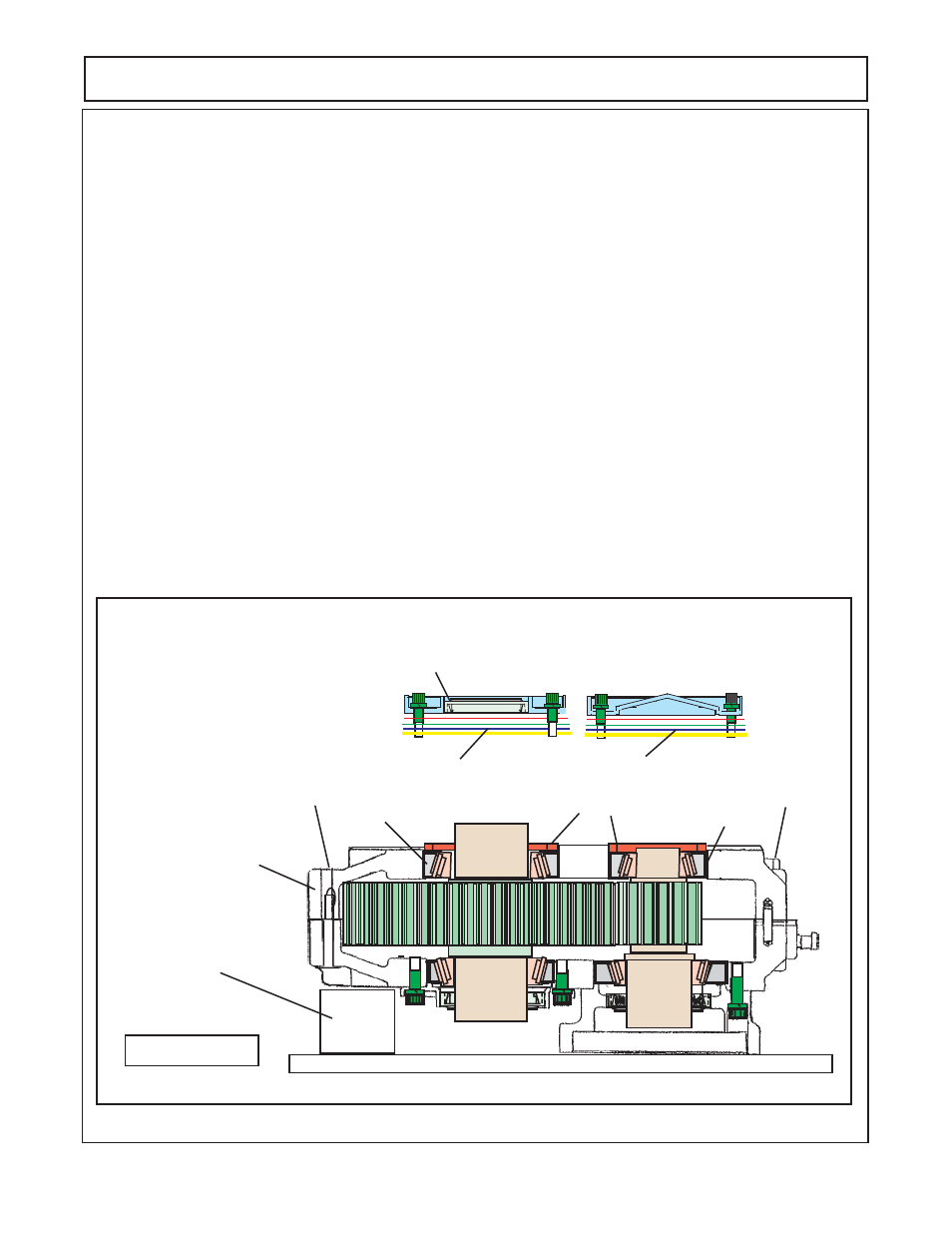

7.

Install the PTO side of housing half

(figure 4 item 15)

. Male certain old gasket has been removed and

gasket face of housing is clean. Aligning the dowel pins

(figure 4 item 17)

between the two housing halves the

PTO side Housing half down over the pump side housing half. It make require a soft hammer to tap the two

halves together. When two halves are together check to make certain gasket has not slipped out. Insert the 8

hex bolts

(figure 4 item 31)

into the 8 holes in the housing halves from the PTO side

(figure 11)

. Install the

Lockwashers and Hex Nuts

(figure 4 item 32 & 33)

onto the 3/8" bolts. Tighten the bolts and nuts in an

alternating pattern and in increments until bolts are snug. Torque the bolts in the same pattern until they are

torqued to 21 to 25 ft lbs.

8.

Install the bearing Cups

(figure 4 items 13 & 19)

the bearing cone

item 13

is smaller than the other 1 and

will only fit the PTO side of the small gear shaft. Bearing cups should be seated against bearing cone at gear

(figure

11). Use only soft hammer and light force to install bearing cups in housing half.

9.

Install the bearing Spacer

(figure 4 item 11 & 35).

The smaller bearing spacer ring goes on the small gear

shaft

(figure 11).

The larger bearing spacer ring goes on the large gear shaft

(figure 11).

10.

Install the second open cover

(figure 4 item 9)

and the closed cover

(figure 4 item 7).

Make certain the ID

of the seal in the open cover is coated with a light coat of grease. The closed cover and the open cover will

require that the shims

(figure 4 items 21, 22, 23, 24, 25, 26, 27 & 28). The amount of shims required will vary.

It is recommended to try to start with the amount that was removed during dis-assembly.

The purpose of the

shims is to set the end play in the bearings and gear shafts

. Add or remove shims as required until the end

play in the gear shaft (Large and Small) is from .007" to .011". The open cover and the closed cover retaining

bolts will need to be torqued 12 to 15 ft lbs. Torque these in an alternating pattern

(figure 11).

123

123

123

123

123

123

123

123

12

12

12

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678

FIGURE 11

Sitting on Block to Make

it Sit on Table Level

PTO Side Housing Half

Insert Hex Head 3/8" Bolt

Washer & Nut

Insert Hex

Head

3/8" Bolt

Washer

& Nut

Bearing Cone

Bearing Cone

Bearing Spacer

12

12

12

12

123

123

123

123

123

123

123

123

123

123

123

Various Shims

Various Shims

Open Cover w/ Seal Installed

Closed Cover