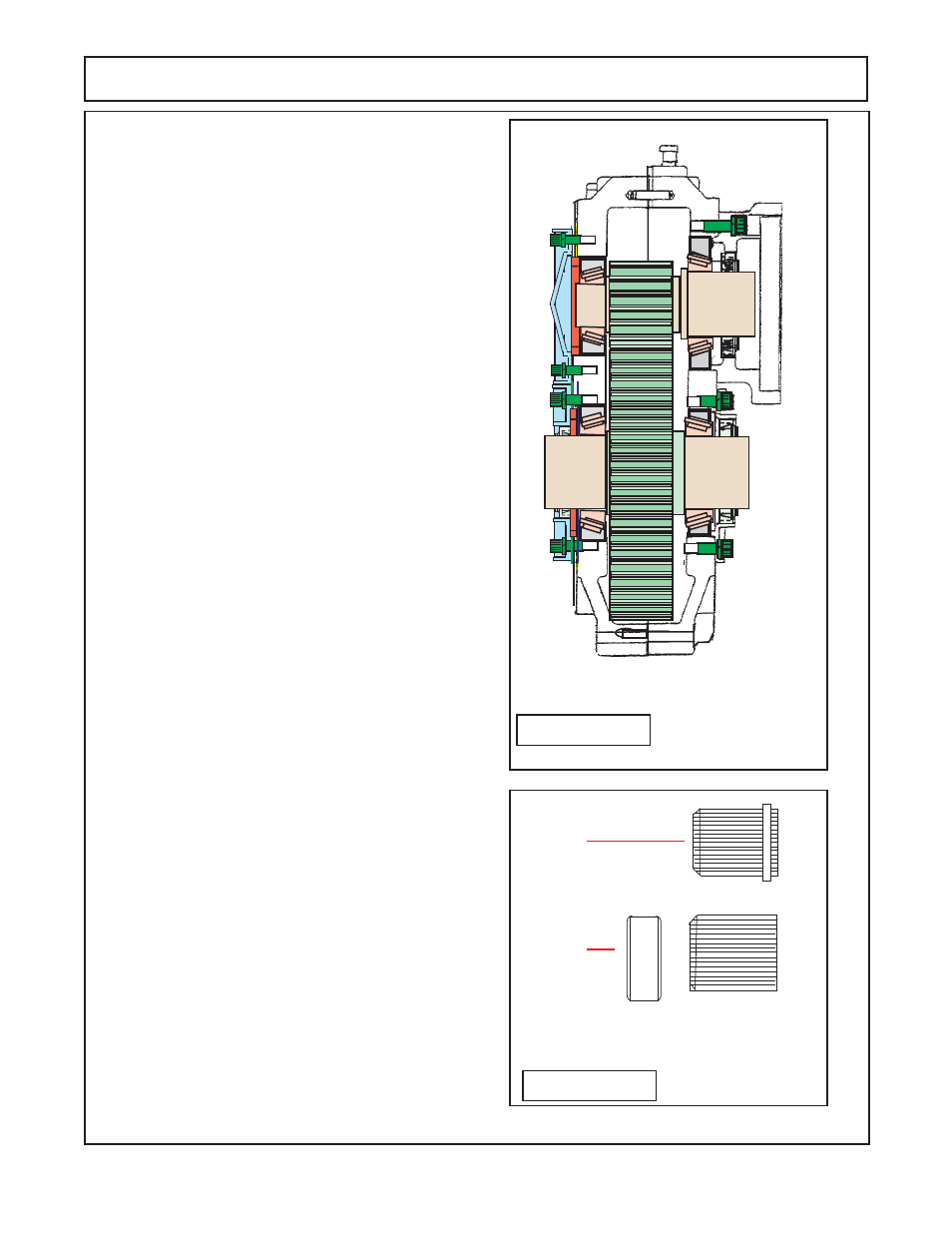

Speed increaser service & repair, Figure 12, A" "b" figure 13 – Alamo HYDRO 15 User Manual

Page 123: Re-assembled speed increaser

Section 7 - 13

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Speed Increaser Service & Repair

FIGURE 12

123

123

123

123

123

123

123

123

1234

1234

123

123

123

123

123

123

123

11.

Reinstall the plugs bag into the correct holes that

they were removed from

(see Part Manual for

holes to

be plugged)

Use pipe sealer for plug,

DO NOT

use teflon

tape.

12

Refill speed increaser with oil, Check the Oil level in

the speed changer Use a recommended grade of oil. A

recommended grade is

SAE 90W oil with E.P. Additive.

Most speed increaser are installed where the pump will

mount above the PTO (figure 1) but in some case it may

require the pump be mounted below the PTO shaft

height. If this is the case the breather plug will need to

be installed in a different location on one of the side

plugs. Normal fill level is the setscrew plug about 1/3 of

the way up on the side of the housing. If Speed in

creaser is turned to the bottom opposite what is shown

in figure 1 the level plug will be the one that was on the

bottom before and would be just below the center line of

the bearings

(figure 3)

13.

Install the splined pump shaft adapter. There are

two types of splined pump adapters that were used.

While either style can be used the components of each

style can not be mixed or left out. Make note of which

style that is being used.

"A"

= Old Style Splined adapter: See figure 1 drawing "A"

.

The old style splined adapter has a snap ring groove

on the OD of it and a snap ring, This splined adapter

pushes into the speed increaser before the pump is

bolted on, the snap ring prevents the splined adapter

from sliding inward and outward inside speed increaser

is in operation.

DO NOT

use with out the snap ring on

splined adapter, failure will occur

(figure 2 & 13).

This

will only fit with the snap ring outward.

"B"

= New Style Splined Adapter: See figure 1 drawing "B"

.

The new style splined adapter

WILL NOT

have a snap

ring groove and

WILL NOT

use a snap ring to keep

adapter stationary during operation. The new style used

a tube type spacer that is slid into the speed increaser

and then the splined adapter is inserted. This tube

spacer will keep the splined adapter from sliding.

DO

NOT

use without the tube spacer installed,

failure will

occur

(figure 2 &13).

This must be installed with the

spacer tube insert first and then the splined adapter to

work properly.

14.

Connect Pump to Speed increaser, See pump

repair service section.

DO NOT

start pump until

looking at pump installation service repair start-up in-

structions.

NEVER

use Teflon tape on any hose or

fittings connections, only thresd sealer on pipe con-

nections.

"A"

"B"

FIGURE 13

Splined Pump Shaft Adapters,

Old & New Style

Re-Assembled

Speed Increaser