Tire - wheel - hub service & repair, Figure 5 – Alamo HYDRO 15 User Manual

Page 128

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 8 - 4

5.

Pull the hub

(item 1)

out slightly while

holding your hand against end of spindle at attaching nut end,

this will allow you to catch the outer bearing cone

(Item 6).

6.

Continued to pull outward on the hub and the hub

(item 1)

will slide off with inner bearing cone

(item 7)

and wheel seal

(figure 3 & 4 item 8)

staying in hub.

7.

Wheel Seals, there are two different types.

Old type

1 piece seal

(figure 3 item 8)

which consist of the

standard type seal as shown in

figure 3 & 5.

New style

3 piece seal

(figure 4 item 8)

consist of, 1 - inner seal

adapter, 1 - inner seal and a outer seal protector which

drives onto the spindle

(figure 4 & 6).

The same type

seal that is removed from the hub must be the type that is replaced.

Parts between these two hubs will not

interchange,

identify which hub you have by the type seal in it before ordering replacement parts. The 3 piece

seal components, seal adapter, seal and seal protector are

not available as individual pieces,

they can only be

ordered as part of the replacement seal assembly.

Remove Seal from Hub,

seal use a soft pin

(wood or plastic)

to drive into the hub from the front side and

against the inner bearing cone, this will drive the inner bearing cone and seal out. If working with the three piece

seal, the seal adapter should come out with the bearing cone.

8.

Bearing Cups, the bearing cups

(items 9 & 10)

can be inspected while still in the hub. If bearing cups are

serviceable and bearing cones are serviceable, then there is no reason to remove the bearing cups from the

hub. If the bearing cup or bearing cone is un-serviceable and either needs replacing then both should be

replaced at the same time, do not use used bearing cups or bearing cones against new bearing cups or bearing

cones.

9.

Grease fitting, it is not required to remove the grease fitting

(item 12)

unless it is damaged or grease cannot

be pumped through it.

Some grease fittings are the drive in type and some are the screw in type. You will be

able to ID these by looking at area where grease fittings enter wheel hub. Drive in grease fittingswill pull out

by clamping them and pulling upward on them.

10.

Clean all components bearings, nut, washer and hub itself. Inspect all components including the wheel

studs

(item 11)

in hub. If wheel studs need to be replace it is recommended that the old stud bepressed out

and the new one pressed in.

11.

Inspect the bearing cups

(item 9 & 10)

, they should not have noticeable wear, scratches, pitting or any

other damage that will make them un-serviceable. If the bearing cups need to be replace the old ones should

be pressed out and new ones pressed in. If the bearing cones are damaged and should be replaced, the

bearing cups should be replaced also or vice versa.

It is not recommended

that old and new bearing cups and

cones be mixed.

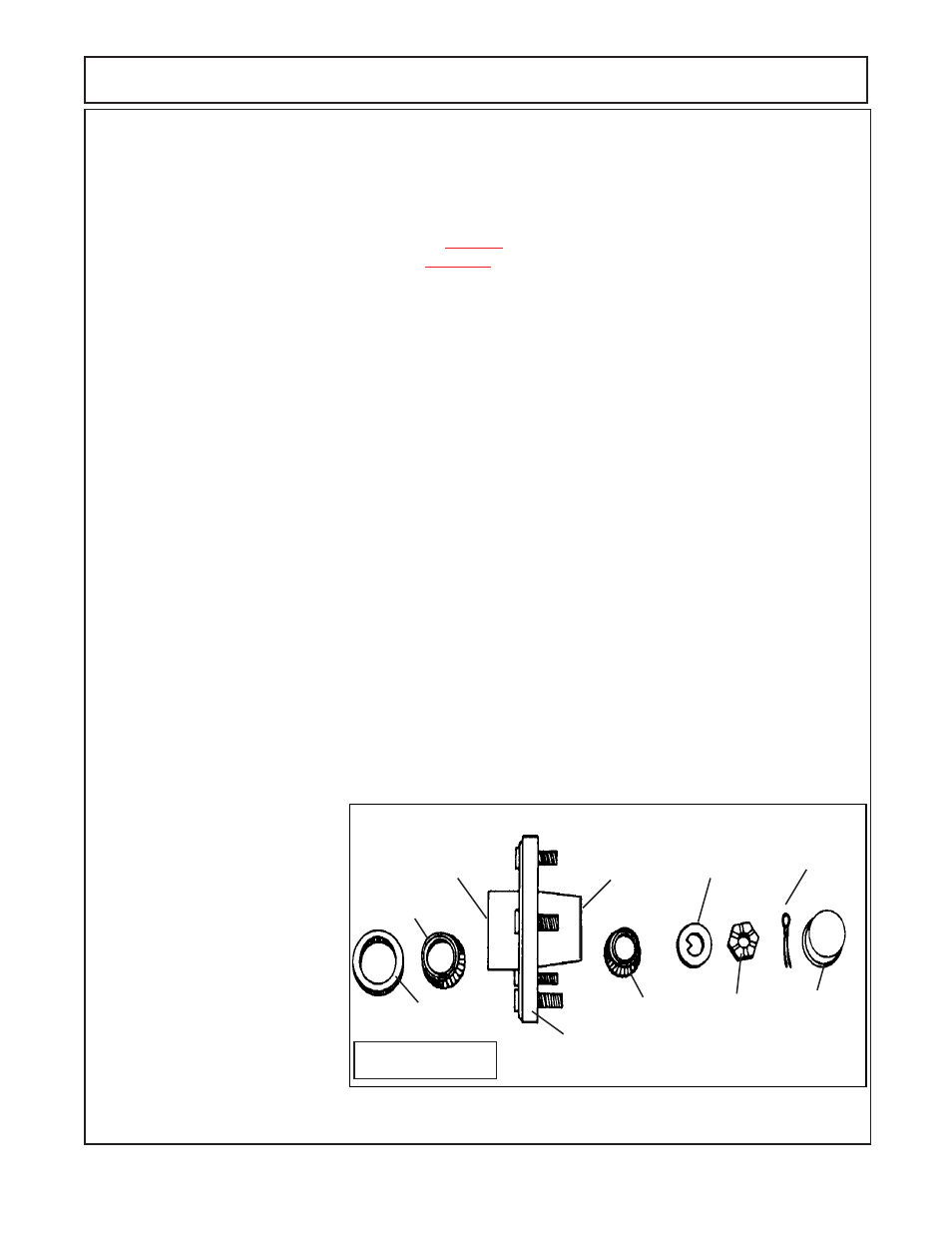

Tire - Wheel - Hub Service & Repair

12.

If hub and components are

washed with solvent (or similar

substance). The component

should be dried with clean filte-

red compressed air.

DO NOT

spin bearing with compressed

air to dry them as this damages

the bearing surface. The inside

of the hub must be cleaned, after

cleaning hub pump small amount

of grease grease through grease

fitting and make certain it is clean

and free of solvent when it comes

out.

Dry all solvent and clean all

Dust Cap

Cotter Pin

Slotted Nut

Washer

Outer

Bearing

Cone

Outer

Bearing

Cup

Inner

Bearing

Cup

Inner

Bearing

Cone

Seal

Wheel Hub

w/ Studs

FIGURE 5

grease from hub ID.

Lay all the components out as inspected, replace components as need

(figure 5).