Pump service & repair, Figure 8 – Alamo HYDRO 15 User Manual

Page 24

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 2 - 8

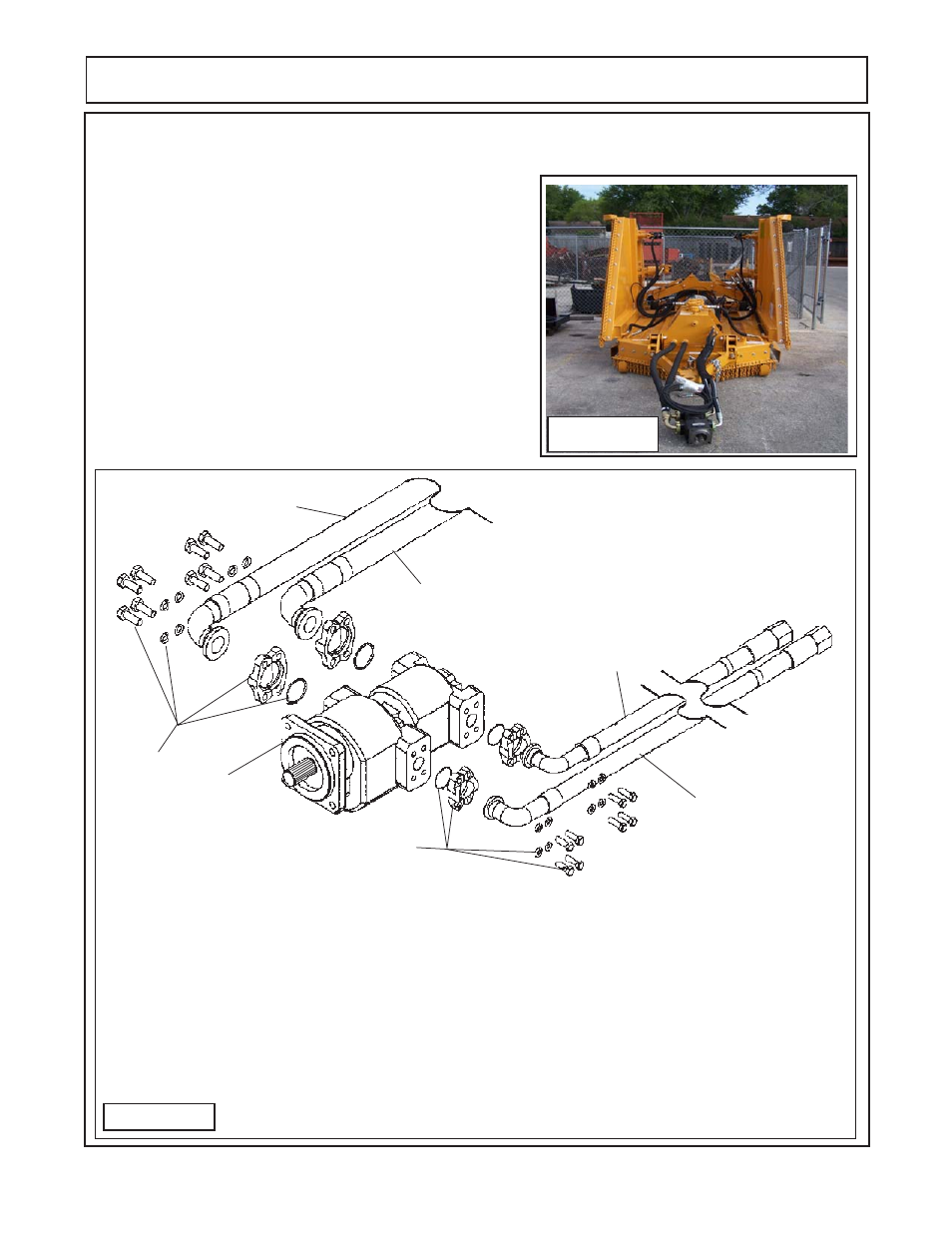

PUMP SERVICE & REPAIR

3

1

2

4

5

6

7

Item

Qty

Description

1

1

Pump Assembly (Tandem Pump)

2

2

Split Flance Kit, (1" Flange)

1

O-Ring (for 1" Flange) (Qty Each Kit)

4

Bolt, Hex Head, (Qty Each Kit)

4

Lockwasher (Qty Each Kit)

3

2

Split Flance Kit, (1-1/2" Flange)

1

O-Ring (for 1" Flange) (Qty Each Kit)

4

Bolt, Hex Head, (Qty Each Kit)

4

Lockwasher (Qty Each Kit)

4

1

Hose Asy, 1" Hose & Flange (Pressure to Wing Motors)

5

1

Hose Asy, 1" Hose & Flange (Pressure to Center Motor)

6

1

Hose Asy, 1-1/2" Hose & Flange. (Suction Hose for Center Motor

7

1

Hose Asy, 1-1/2" Hose & Flange. (Suction Hose for Wing Motor)

Tandem Mounted Pump

Figure 9

Pump Cleaning & Removal:

1.

Clean Pump, Hoses and all connections before discon-

necting any components from the pump. This will keep con-

tamination from getting into system. Figure 8 shows the pump

and hoses connected to the mower (this mower is new, clean

and un-used) with the pump sitting on the ground, if the hoses

are to be dis-connected, the pump should mounted up and

above the hydraulic tank (on work bench, hoist, etc.). What

ever the technician decides to mount pump on. Some type of

drain pan will be required to catch the oil that will drain out when

hoses are dis-connected. The hoses will need to be capped

(plugged) after removal being disconnected. If cap is not leak

proof then hoses must remain elevated above hydraulic tank to

prevent oil leakage from hose fittings. Figure 9 shows how the

hoses are connected. Hoses are connected with 4 bolt split

flange kits (1-1/2" on suction side &1" on pressure side)

Figure 8