Spindle assembly - service & repair, Figure 28 figure 29, Figure 27 – Alamo HYDRO 15 User Manual

Page 72

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 4 - 8

10.

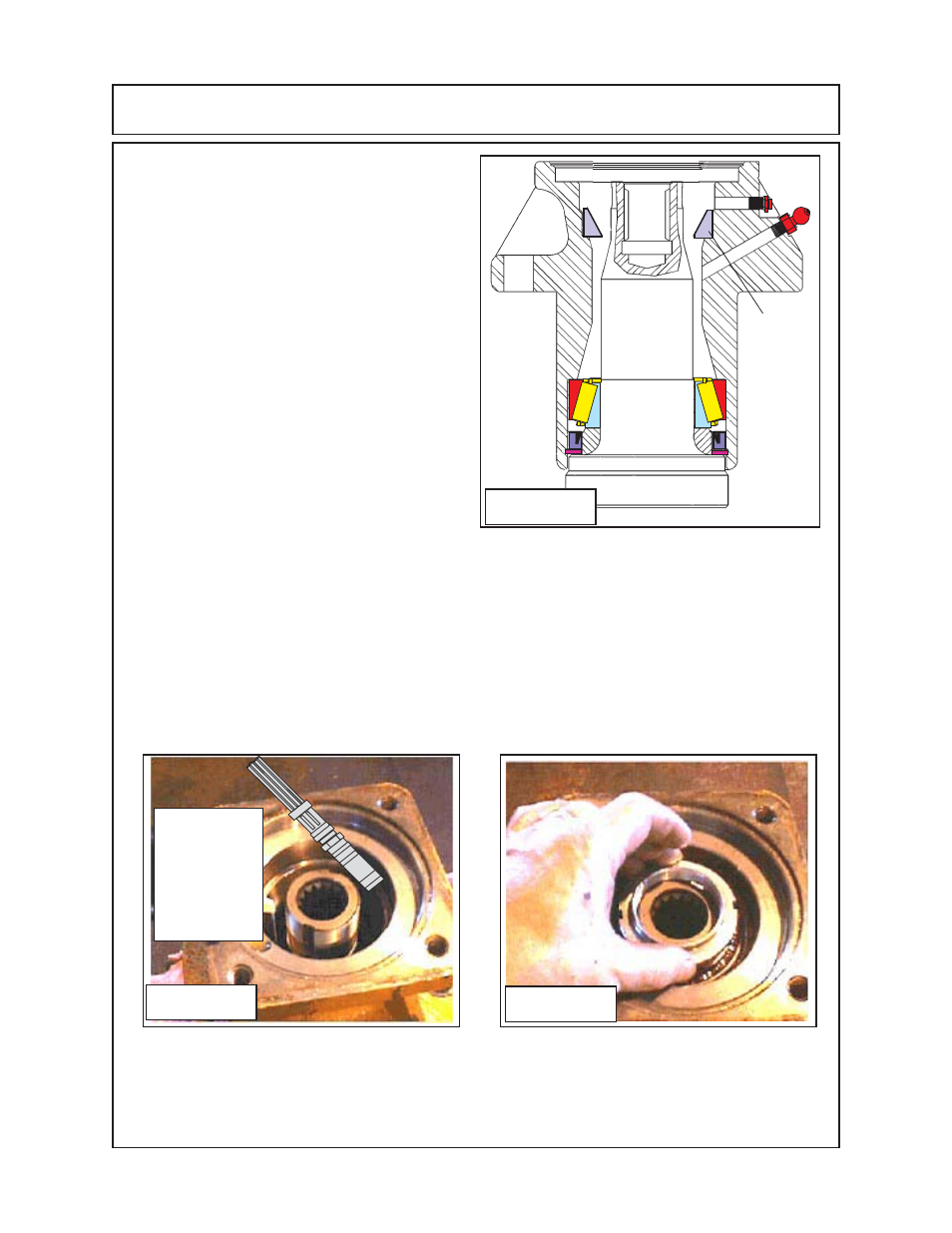

Tighten the new Lock Nut with a 4 prong socket and hand ratchet until tight Back the nut

off until 12 to 15 INCH POUNDS of rolling resistance is achieved

(figure 29).

11.

Use a punch to stake the bearing nut in place. Be sure to stake the nut at both slot

locations.

(figure 30).

12.

Useing the grease fitting to the side of the spindle housinf pump grease in to spindle

housing. Watch the upper bearing cone, when grease is being forced through the roller

bearings of the upper bearing cone spindle is full

(figure 31).

13.

Install the new motor flange gasket. Apply a thin film of silicone to both sides of the gasket

to ensure a good seal

(figure 31).

7.

Fill the spindle housing with

NLGI EP #

2 grease

Alamo Industrial PN 00900000

(figure

28).

The proper level will be up to the

upper bear cup bottom side for now,

do not

fill with grease

above the bottom of upper

bearing cup

, if you do it will interfere with

adjusting bearing preload.

8.

Pack the upper bearing cone with

grease completely. Install upper bearing

cone down over the top of the spindle shaft,

if needed use a bearing driver to seat

bearing cone into bearing cup

9.

Apply Locktite # 277

to the spindle

threads where the bearing nut screws on,

It may require grease to be cleaned off of

threads to apply locktite.

(figure 29) .

Start

the New Locknut onto the shaft threads,

the nut should start by hand, make certain

it is started straight.

(figure 29).

Figure 28

Figure 29

Use Grease

Gun to put

Grease into

Spindle, Fill to

bottom of

Upper Brg Cup

only for now.

SPINDLE ASSEMBLY - SERVICE & REPAIR

Figure 27

Upper

Bearing

Cup