Motor service & repair, Figure 22, Figure 21 figure 20 – Alamo HYDRO 15 User Manual

Page 52

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Section 3 - 14

Figure 22

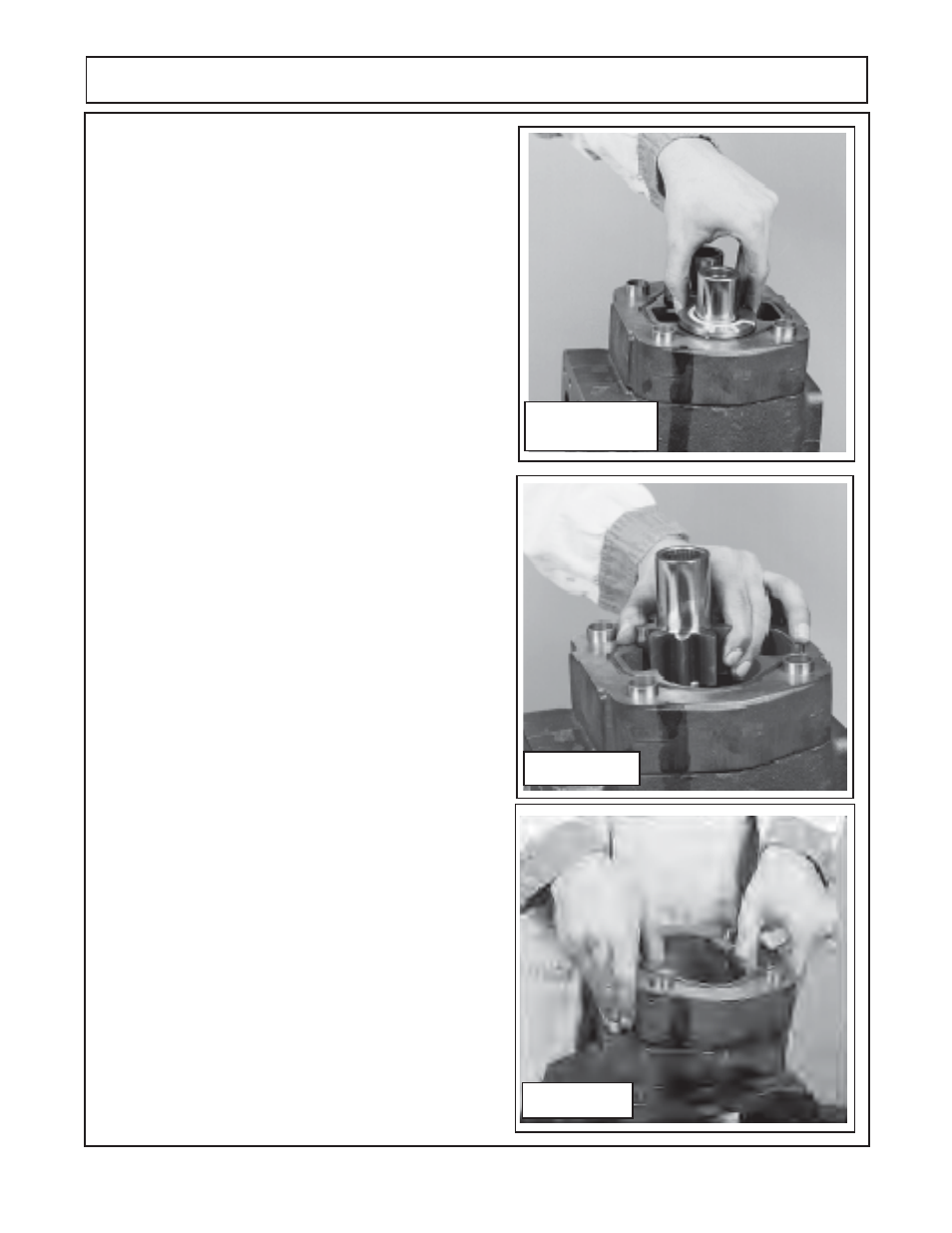

6.

Inspect the thrust plate for damage or wear at this

time

(see wear tolerance

chart for pump and motors in

this section)

, this will help in looking for other wear or

damage to other components and also enable you to start

making a list of components that need replacing.

(figure

25)

7.

Carefully remove drive gear and driven gear

(figure 21)

.

Avoid tapping the gear teeth together or against other

hardened surfaces

(figure 21),

Keep these gears together

as they are a matched set. Examine the gears for wear

and damage. Note the dowels

(figure 21 & 22)

that are in

gear housing, sometimes these will come out and be in

the end cover or they may stay in the gear housing. It will

be OK as long as the same components are to be

reassembled, but if some components are to be replaced

and some are not then these dowel pins will have to be re-

moved and re-inserted.

IMPORTANT! If working on center, LH & RH motor at

same time it is important not to mix the components of the

motors. Keep the Gears separated between the motors as

gears are matched sets. DO NOT mix used gears and new

gears a motor.

8.

Remove the second thrust plate

(figure 21)

, the 2nd

thrust plate is at the bottom of gear housing and is visible

after gears have been removed. Make a note how this was

removed, there is a smooth side and there is a grooved

side. The smooth side will always face the gears, the

grooved side is for channel seals. Inspect the thrust plate

for damage at this time

(see wear tolerance

chart for pump

and motors in this section)

. Note: Thrust plate can be re-

moved after gear housing if wanted

. (figure 25).

9.

Remove the gear housing (

figure 22)

. Lift the gear

housing up, if prying is necessary take care not to damage

machined surface. Examine gear housing for wear and /

or damage.

(See wear tolerance

chart for pump and

motors in this section).

10.

Remove shaft end cover

(figure 23)

from vice and turn

it 180° over and re-insert it into vice. Using snap ring pliers

remove the snap ring

(figure 23)

as shown.

11.

Remove the seal retainer cup

(figure 15)

The seal

retainer cup should pull up out of the end shaft cover. If it will

not go on to step 12 and remove the retainer cup with the

seal.

12.

Remove shaft end cover

(figure 10 item 4)

from vice and

turn it 180° over and re-insert it into vice. Remove the

double lip seal by inserting the special seal removal tool

(see figure 6 recommended tools).

Make note of which way

seal is removed. Inspect the shaft end cover seal seat area

(figure 24).

MOTOR SERVICE & REPAIR

Figure 21

Figure 20