Pump service & repair, Pump dis-assembly caution, Pump dis-assembly – Alamo HYDRO 15 User Manual

Page 27

Section 2 - 11

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

PUMP SERVICE & REPAIR

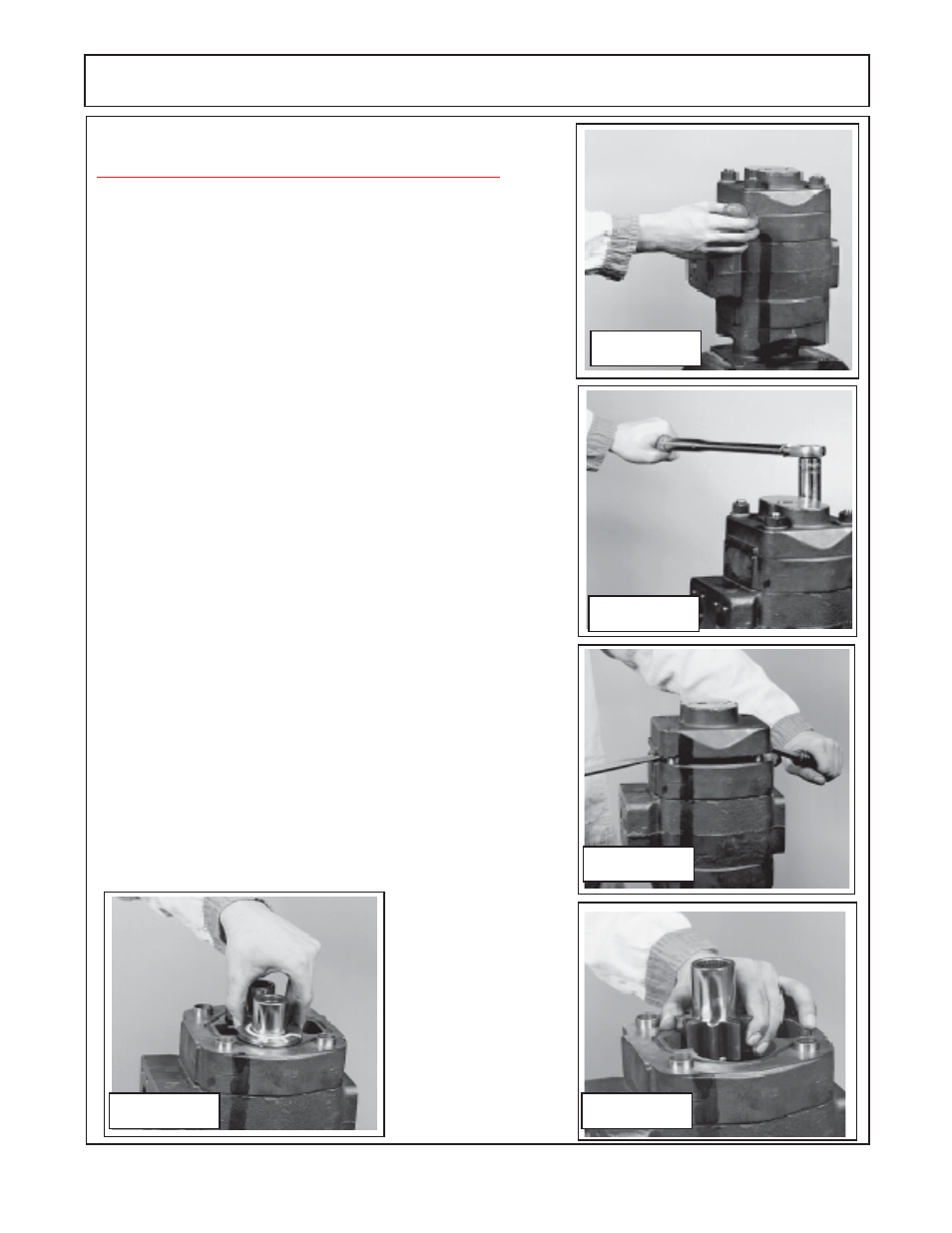

Pump Dis-Assembly CAUTION! :

Important information - read before dis-assembly:

1.

If prying off sections becomes necessary, take extreme

care not to mar or damage machined surfaces. Excessive

force while prying can result in misalignment and seriously

damage parts.

2.

If parts are difficult to come apart during dis-assembly,

tap gently with a soft hammer (never use an iron hammer).

3.

Gears are closely matched, therefore they must be kept

together as sets when removed from the pump. Handle

gears with care to avoid damage to journals or teeth. Avoid

touching gear journals.

4.

Never hammer bushing into bores: always use an arbor

press.

Pump Dis-Assembly:

1.

Place the pump in a vise with the drive shaft pointing down.

Caution

DO NOT

grip on or near any machined surfaces of pump

during assembly or dis-assembly. Mark all sections of the pump

(figure 10A)

, these marks must be done in a manner that will not

wash off and these marks are to identify the orientation of the

component of the pump later for re-assembly. It is recommended

that marks be done with metal stamps that will mark components

for correct assembly order for & during re-assembly. This is

very

important

as if any of the sections of pump are installed in the

wrong direction it could damage pump when re-assembled or when

pump is engaged during operation

(figure 11).

2.

Use a socket Wrench or Boxed end wrenches

(Air impact

wrenches are not recommended for dis-assembly).

Remove the

four hex bolts and washers

(figure 10 item 19 & 20)

, This will allow

for the removal of the outward half of the pump. The inward section

is still connected together with the studs and nuts which will be

removed in a later step. Inspect the bolts for thread condition. If

bad threads on bolts most likely the threads in that hole are bad,

mark the hole so it can be check later.

Figure 11

Figure 12

Figure 13

Figure 14

Figure 15