Wing lift & fold cylinder repair, 6 & 6c 7 – Alamo HYDRO 15 User Manual

Page 87

Section 5 - 13

HYDRO 15 (Service Manual) 10/06

© 2006

Alamo Industrial

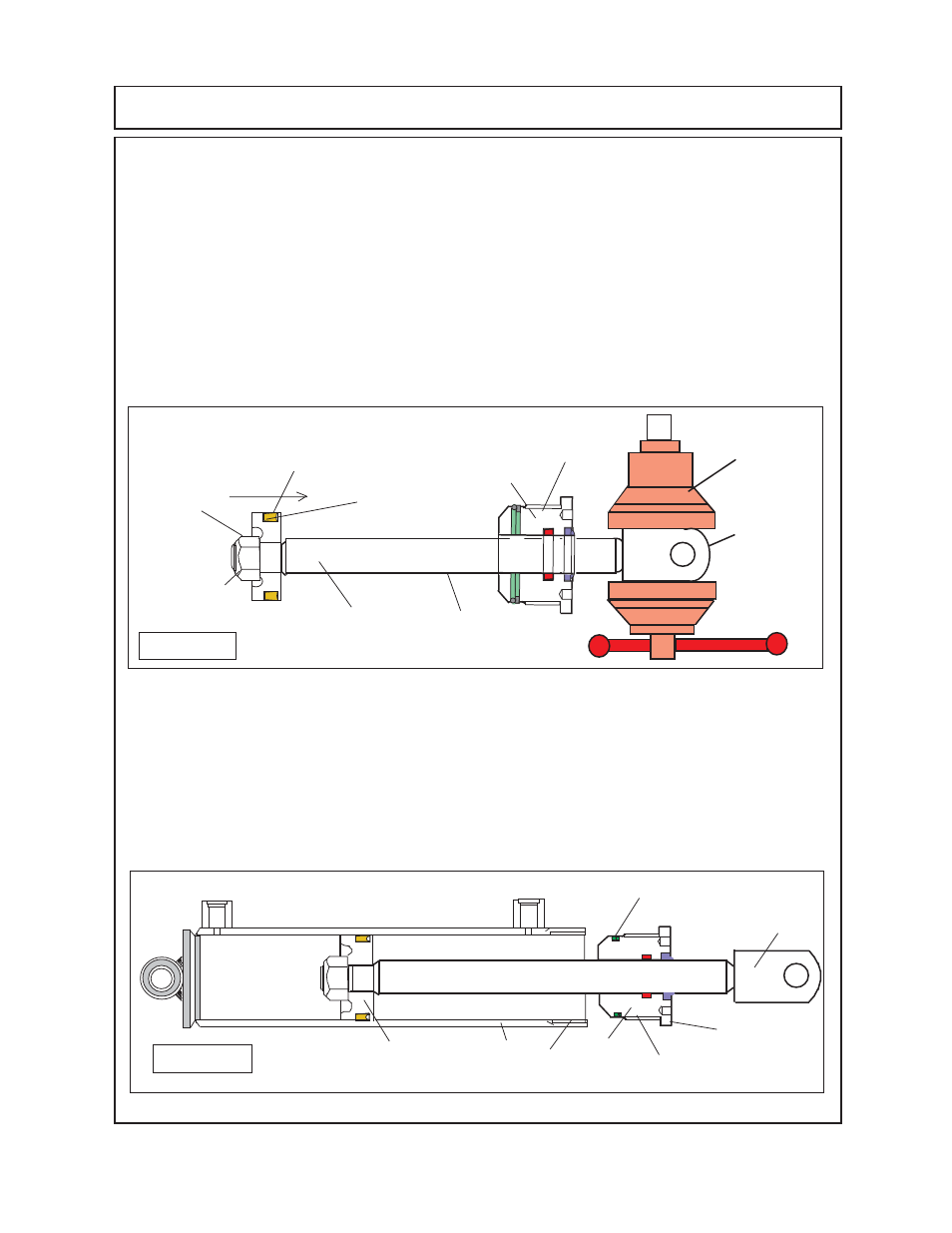

11.

Coat the piston

(figure 10 item 6)

and ID of the barrel

(figure 11 item 5)

with light coat of hydraulic

oil. Clamp the barrel down just enough to hold it being careful not to over tighten it, or the barrel

could be distorted. Holding the cylinder rod straight slowly slide the piston into the barrel, be careful

at the front of the barrel when sliding piston across the threads in the barrel

(figure 11 Item 5

Threads)

so as not to damage U-Cup seal on piston

(figure 11 item 6)

. When piston is being slid

into barrel do it slowly feeling the resistance, the resistance should remain about the same all the

way in, if not recheck barrel for wear. Continued to slide piston in holding rod as straight as possible

until it is in barrel approx 10 to 12 inches making certain the cylinder head

(figure 11

item 4)

is not

inside barrel.

WING LIFT & FOLD CYLINDER REPAIR

8.

Install the U-Cup Seal

(figure 10 item 6C)

onto Piston

(figure 10 item 6)

. The U-Cup Piston seal

is a directional seal and is designed to be used as a single action cylinder. The U-Cup seal should

be installed so the U-Cup side of seal is toward the pressure side of the piston which is the rod

side on this cylinder.

9.

The cylinder rod weldment is clamped into vice as shown

(figure 10 item 3)

Clamp the rod with

the mounting pin hole upward as shown

(See Rod Clevis Weldment figure 10 item 3)

, if the clevis

is clamped with the hole the other way, the clevis could be bent together and cause the clevis to

be deformed.

10.

Install the new Piston retaining locknut

(figure 10 item 7)

onto the cylinder rod. (Note it is not

recommended that old locknut be reused). Before tightening the locknut down make certain that

piston is seated onto cylinder rod completely, this can be done by visually inspecting back side of

piston against shoulder of cylinder rod. Torque Piston Locknut

350 to 400 ft lbs.

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

1234567890123456789012345678901212345678901234567

1234567890123456789012345678901212345678901234567

1234567890123456789012345678901212345678901234567

1234567

1234567

1234567

123456

123456

1234567

4

3

Figure 11

5

Cyl Head

6

Cyl Head

Threads

Barrel

Threads

O-Ring & Back-Up Washer Seal

3

Figure 10

Vise

Cyl Rod

Clevis

Weldment

12345

12345

12345

12345

12345

Cyl Rod & Clevis

Weldment

Cyl Head

4

1234567

1234567

Piston w/ U-Cup

Seal Installed

6 & 6C

7

Piston

Locknut