Optional axle level lift cylinder repair – Alamo HYDRO 15 User Manual

Page 102

HYDRO 15 (Service Manual) 10/06

© 2006

Alamo Industrial

Section 5 - 28

5.

Install the new nylon thread protector

(figure 6 item 2)

into the cylinder rod clevis

(figure 6 item

2)

, Make certain the nylon thread protector is laying flat in the bottom of the threaded hole in the

clevis. Insert the setscrew

(figure 6 item 2)

into the clevis

(figure 6 item 3)

. Tighten the clevis

setscrew to

20 ft. lbs.

6.

Clamp the barrel

(figure 8 item 5

) in vise using wood or other soft material to protect barrel

(see

figure 8)

,

DO NOT

tighten vise so tight that the barrel becomes distorted. Make note that the mark

that was made to identify which end of the barrel was the rod end is verified. Coat the inside of the

barrel with hydraulic oil.

7

Coat the piston, cylinder rod, cylinder head seals with hydraulic oil. Holding the rod, clevis,

cylinder head and piston as an assembly.

(see figure 7)

slide the assembly into the barrel. Make

certain that the insertion is on the same end as when it was removed

(Not required only

recommended).

Make certain the port of the cylinder head

(figure 8 item 9)

is pointing up as shown

this will make certain of port alignment when base end of cylinder is installed.

8.

Install the new nylon thread protector

(figure 6 item 2)

into the cylinder rod clevis

(figure 6 item

3)

, Make certain the nylon thread protector is laying flat in the bottom of the threaded hole in the

clevis. Insert the setscrew

(figure 6 item 2)

into the clevis

(figure 6 item 3)

. Tighten the clevis

setscrew to

20 ft. lbs

(base on 3/8” setscrew).

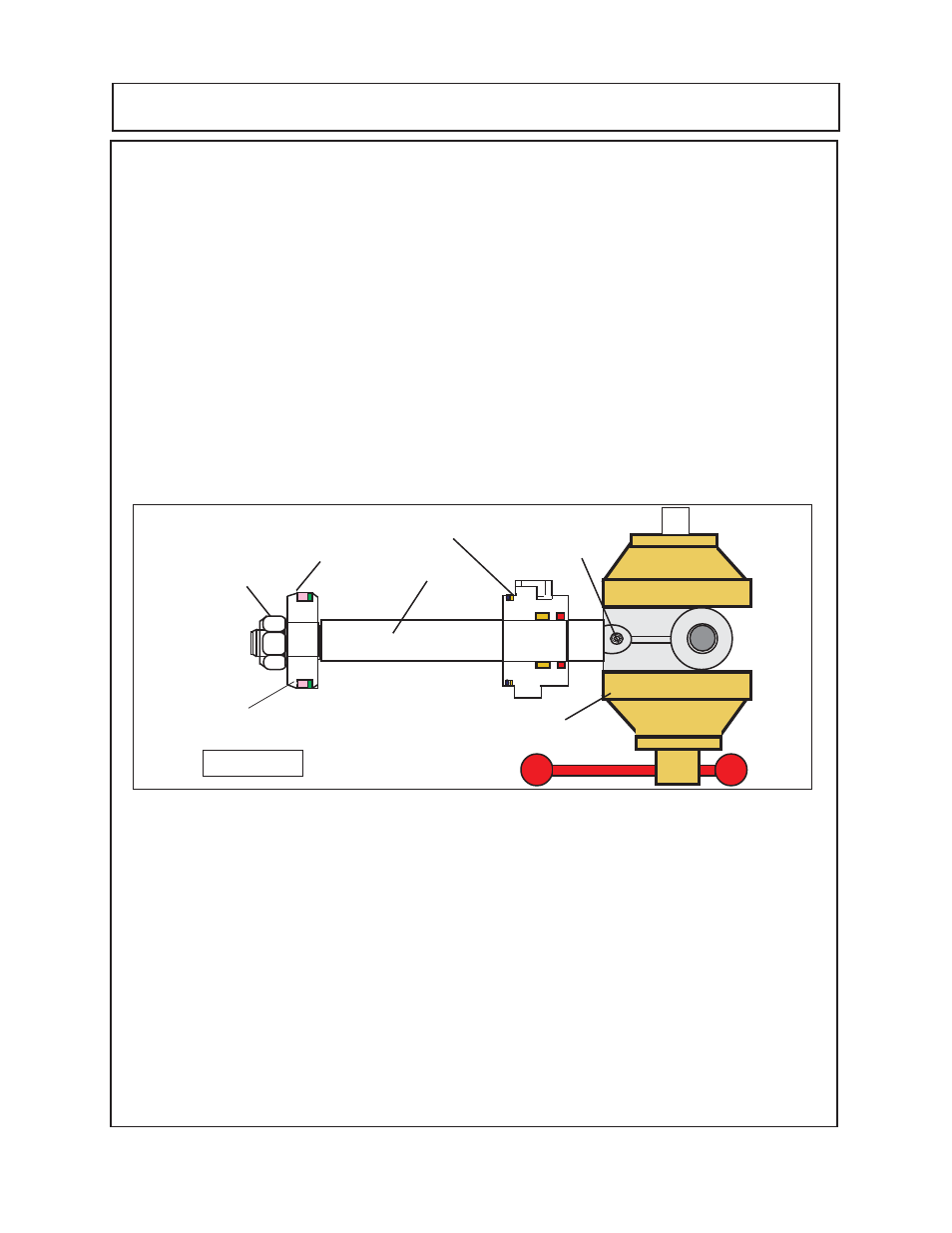

Cylinder Re-Assembly: (Axle Level Lift Cylinders, Optional)

1.

Clamp cylinder rod clevis into bench vise

(figure 6 item 3 see figure 7)

. Make certain the old

nylon seal protector has been removed before attempting to screw cylinder rod into clevis.

(figure

6 item 2). Using

a strap wrench if needed screw the cylinder rod

(figure 6 item 4)

into the clevis

(figure 6 item 3)

, tighten rod until it is screwed in flush with cylinder rod

(see figure 7)

. Important!

DO NOT

install nylon thread protector or setscrew

(figure 6 item 2)

into clevis at this time, it is best

to do this later after piston and piston nut has been installed.

2.

Replace the seals in the cylinder head

(figure 6 item 9),

base clevis

(figure 6 item 8)

and piston

(figure 6 item 15)

. Make certain to put the seal on in the correct order

(figure 6 & 7).

3

Installing the Piston on the cylinder rod (figure 6 & 7 item 15) may require a press,

DO NOT

try to press piston onto cylinder rod with the piston nut.

Use Locktite 271 or equivalent

when

pressing piston onto cylinder rod. Make certain piston and rod are in alignment when pressing

piston, make certain piston and rod are protected from damage.

4.

Install the new Piston retaining locknut

(figure 6 & 7 item 14)

onto the cylinder rod. (Note it is

not recommended that old locknut be reused). Before tightening the locknut down make certain

that piston is seated onto cylinder rod completely, this can be done by visually inspecting back side

of piston against shoulder of cylinder rod. Torque Piston Locknut

300 ft lbs

(based on 1” locknut).

When tightening piston locknut if support for cylinder rod is needed

(see figure 4)

.

OPTIONAL AXLE LEVEL LIFT CYLINDER REPAIR

Figure 7

123456

123456

123456

123456

123456

123456

Bench Vise

Cylinder Head

Clevis Set Screw

Piston

Cylinder Rod

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

1234567890123

12345678

12345678

12345678

12345678

12345678

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

Piston Nut

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123456

123

123

123

12

12

12

12

Chamfered side of piston