Pump service & repair, Figure 22, Figure 23 – Alamo HYDRO 15 User Manual

Page 29

Section 2 - 13

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

Figure 19

Figure 20

Figure 21

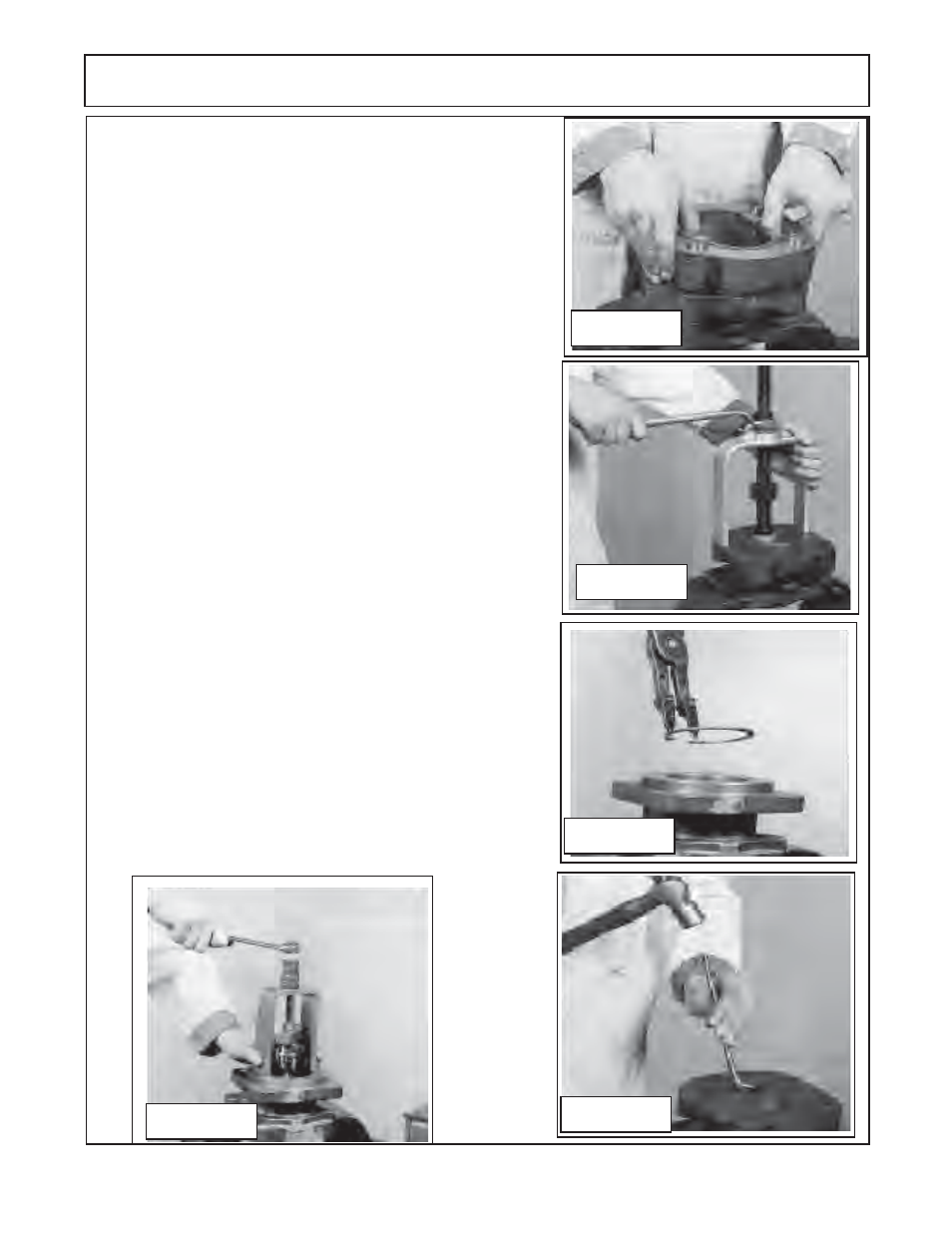

9.

Lift or pry off the first section of gear housing

(figure 10 item

12).

Be careful not to damage machined surfaces

(figure 19).

Inspect the gear housing

(See wear tolerance

chart for pump

and motors in this section).

for wear and / or damage.

10.

Inspect all of the bushings for scoring or discoloration

(figure

10 item 6 qty 8)

in the port end cap, bearing carrier (both sides)

and the shaft end cover. If they need to be replaced use a

bushing puller as shown

(figure 4 recommended tools list)

.

Remove the bushings with care not to damage housings

(figure

20).

11.

Remove shaft end cover

(figure 10 item 4)

from vice and turn

it 180° over and re-insert it into vice. Using snap ring pliers

remove the snap ring

(figure 10 item 1)

as shown

(figure 21).

12.

Remove the shaft bearing

(figure 10 item 2)

using a bearing

puller

(figure 22).

Make certain to use the correct size bearing

puller and that puller is inserted straight.

13.

Remove shaft end cover

(figure 10 item 4)

from vice and turn

it 180° over and re-insert it into vice. Remove the double lip seal

by inserting the special seal removal tool

(see figure 6 recom-

mended tools).

Make note of which way seal is removed. Inspect

the shaft end cover seal seat area

(figure 23).

14.

Inspect all the components that have been removed (

review

steps 1 through 13).

There are 4 gasket seals (

figure 10 item 10)

that are installed, one on each side of the gear housing. Make

certain the gasket seal have been removed and the gasket

grooves are clean. Wash and clean all the components,

DO NOT

use any material that will leave lint on components, it 's best to

air dry the components. Use extreme caution when cleaning

gear sets, DO NOT use any abrasive materials at all and

DO

NOT

bang the gears together. Keep the gears in the same sets

as they were remove as they are a matched set and must

remain as a set.

(See next two pages for wear identification).

Figure 22

PUMP SERVICE & REPAIR

Figure 23