Motor service & repair, Recommended tools, Figure 4 – Alamo HYDRO 15 User Manual

Page 45: Figure 5, Figure 6, Figure 7

Section 3 - 7

HYDRO 15 (Service Manual) 09/06

© 2006

Alamo Industrial

MOTOR SERVICE & REPAIR

Recommended Tools:

Listed below are some of the toolds that

are recommended for the dis-assembly and re-

assembly of the pump for the HYDRO 15 Mower.

1.

Arbor Press

2.

Awl

3.

1-1/2" Dia steel ball

4.

Bearing Puller (Owaonna Tool Co.

MD-956 or equivalent)

5.

Bushing Remover Tool (figure 4)

6.

Clean lintless Cloth

7.

Deburing Tool (an old file with cutting

teeth ground off)

8.

Machinest Hammer

9.

Soft Hammer

10. Permatex Aviation Form-A-Gasket.™

(No. 3 non hardening sealant or equal)

11. Medium Grit Carborundurn Stone.

12. Seal removal Tool (figure 6)

13. Oil and Grease

14. Snap Ring Pliers

15. Prick Punch

16. Bushing Installation Tool (figure 5).

17. Scale (1/32" or 1/64" graduations)

18. Small Screw Driver

19. Torque Wrench (in. lbs & ft lbs)

20. Vise with 6" minimum opening

21. Bar for Lip Seal Installation

For Center or Wing Motor

use 2-1/2" dia X 2" Bar

22. Special Steel Sleeve (figure 7)

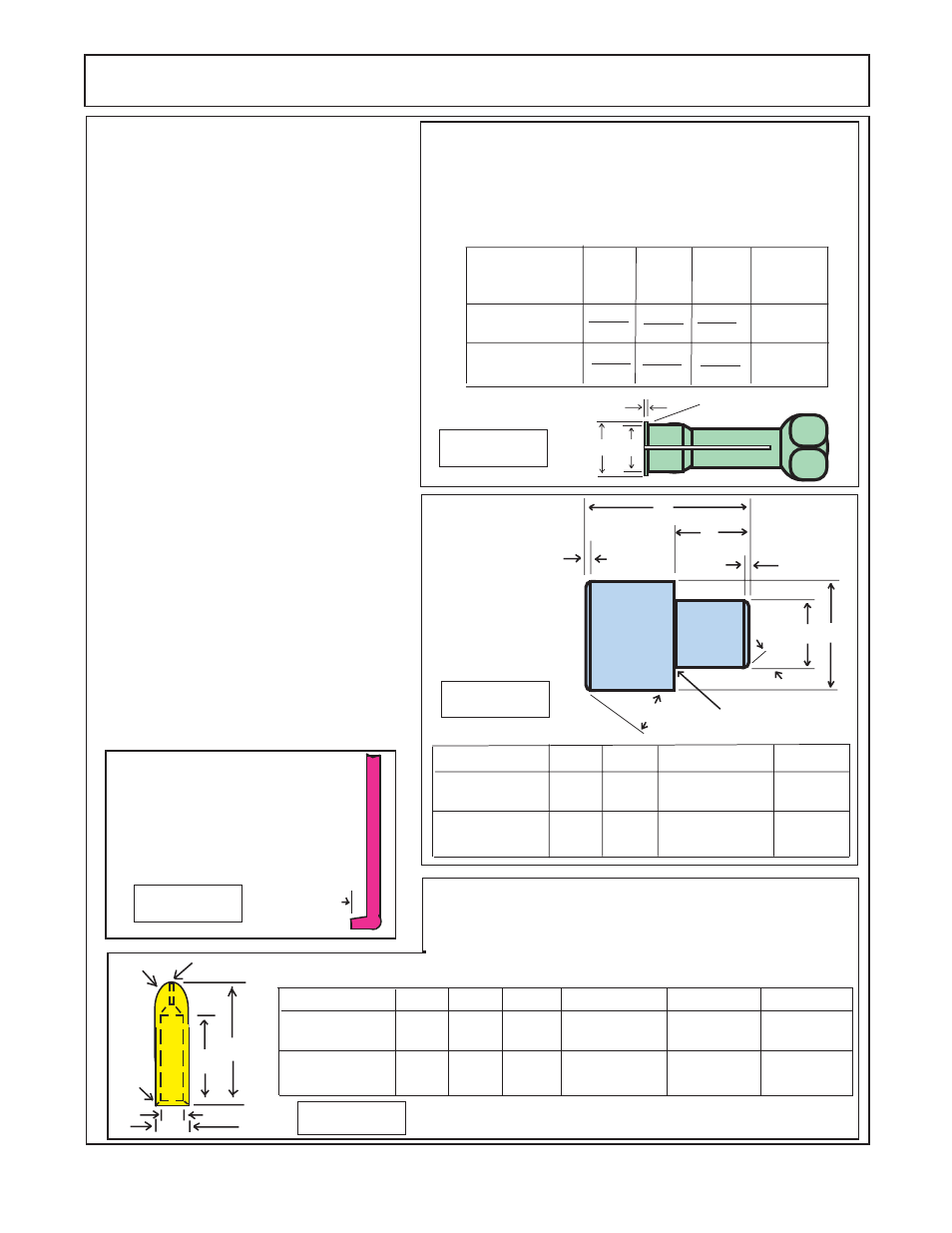

Bushing Puller: The bushings in the Motor may be

removed from tier bores, using blind hole collet-type bushing

pullers similar to those manufactured by Owatonna Tool Co. The

Table below illustrates the modification necessary to adapt the

OTC collets to this task. Equivalent pullers from other suppliers

may be modified in a similar fashion.

Motor

A

B

C

Make

f/ OTC

Collet No.

Wing Motor

1.122

1.122

1.000

0.990

.072

.062

33864

Center Motor

1.382

1.372

1.260

1.250

.100

.120

33865

Figure 4

.015 R Maximum

C

A

B

30°

30°

C

D

B

.06

.06

A

Grind Relief Allowable

Surface

Finish

32

Bushing Installation

Tool A.I.S.I 8620

Bearing Qaulity

Steel Heat treated

Figure 5

Seal Removal Tool: Easily

made from old screw driver.

Heat the tip and bend as

shown. Grind the tip to fit the

notch behind the shaft seal.

1/4"

Figure 6

Special Steel Sleeve: The special steel sleeve is used to insert the

drive shaft through the lip seal without damage and can be made

from bar stock. For the center motor use a 1-1/2" dia X 4-5/8" bar.

For wing motor use a 1-3/8" dia X 4-5/8" bar. The drawing and cgart

give details for making this special tool.

C Rad

1/4" Hole Drill through

A

B

F°

E

D

Motor

A

B

C dia.

D dia.

Wing Motor

1.47

1.282

1.625

Center Motor

3.00

+ .000

- .002

3.00

1.73

1.492

+ .000

- .002

1.750

Figure 7

Motor

A

B

C Rad

F° Chamfer

Wing Motor

4-1/2"

1.290

.015" X 60°

Center Motor

3-3/8"

+ .000

- .002

3-3/8"

4-1/2"

1.250

9/16"

D Rad

E dia.

1.250 + .002

- .000

9/16"

1.377

+ .000

- .002

+ .002

- .000

.015" X 60°

All external surfaces MUST be free of scratches and burrs