Standard axle lift cylinder repair – Alamo HYDRO 15 User Manual

Page 90

HYDRO 15 (Service Manual) 10/06

© 2006

Alamo Industrial

Section 5 - 16

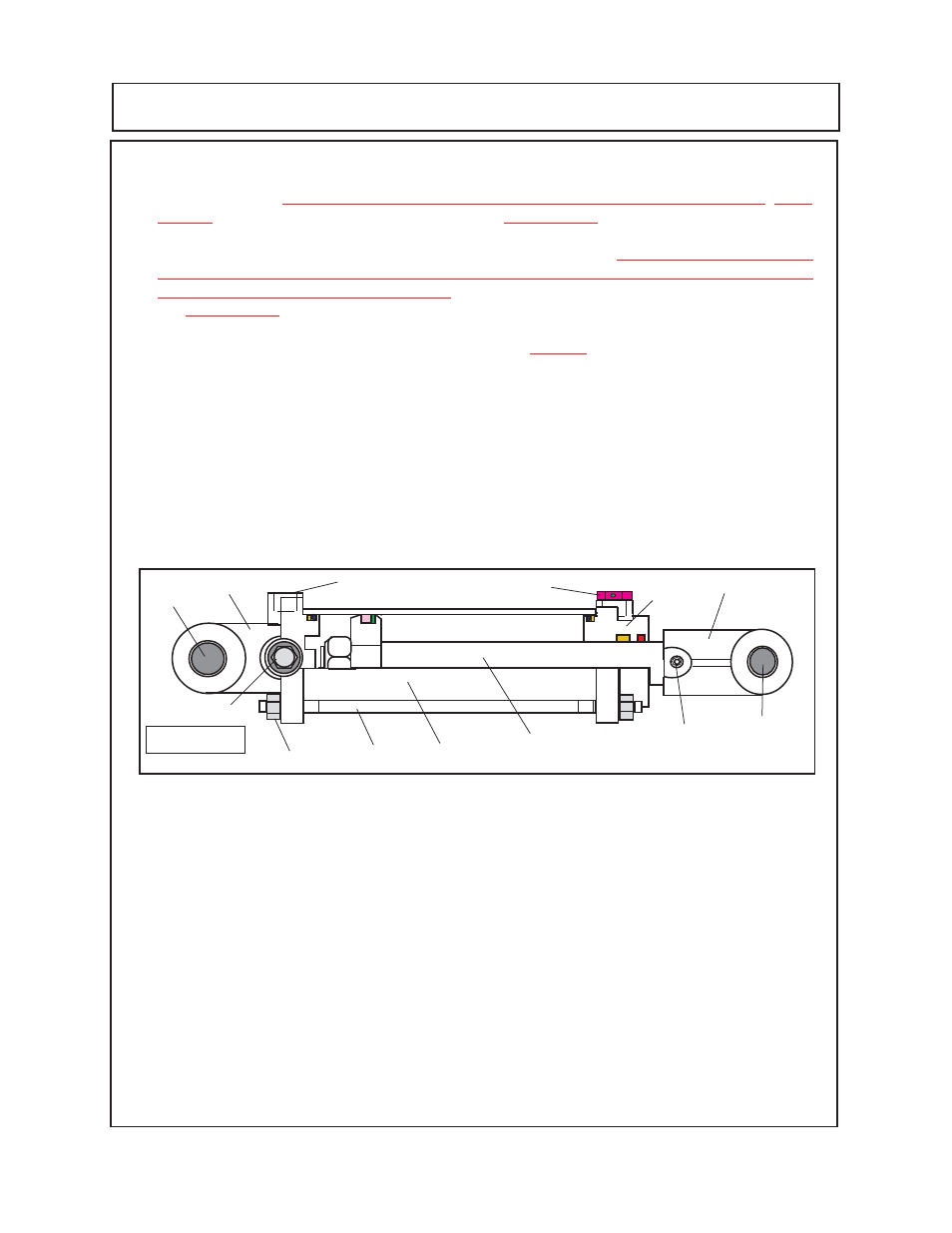

STANDARD AXLE LIFT CYLINDER REPAIR

Cylinder Removal: ( Axle Lift Cylinder, Standard)

1.

Make Certain

axles are in the lowered position before disconnection any component

.

Make

certain tractor is securely parked with brakes set

.

Make certain

tractor engine is in off position

and

key secured to prevent starting

. It is recommended mower be disconnected from tractor or

battery cable be removed from battery while repairs are being made.

Front and rear of mower must

be securely supported on strong jackstands before hydraulic lines or cylinder mounting pins of the

axle hydraulic assembly are disconnected.

2.

Make certain

that all hydraulic pressure has been released from lines after wings and axles

have been completely lowered. This may require the tractor hydraulic controls and / or remote

control valve be worked to release hydraulic pressure.

NEVER disconnect any cylinder hydraulic

hose's or fittings if all

mower components (wings and deck) are not resting in the completely

lowered to the ground position or supported on jackstand position.

3.

Do not remove cylinder pressure hose before the cylinder is dismounted from deck. Remove

the cylinder mounting pins

(figure 1 item 1)

, this allows the cylinder to be raised upward off the deck

mounting lug and the axle lug. Place a drain pan under the pressure hose to catch the hydraulic

oil when hose is disconnected. Drain cylinder and hose into drain pan. Plug the pressure hose to

keep contamination out of it.

4.

Plug all openings in cylinder before cleaning the cylinder. Remove the Vent Plug

(figure 1 item

10)

and insert a plug

(plastic plugs will work)

. Base end of cylinder

(figure 1 item 8)

will have two

ports, Pressure hose port

(figure 1 item 11)

and second plugged port on side

(figure 1 item 12)

which

should still be in cylinder base.

1234567

1234567

1234567

1234567

1234567

1234567

1234567

1234

1234

1234

1234

1234

1234

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

12

12

12345678901234

12345678901234

12345678901234

12345678901234

12345678901234

12345678901234

12345678901234567890123456789012123456789012345678

12345678901234567890123456789012123456789012345678

12345678

12345678

12345678

1234567

1234567

12

12

12

12

12

12

12

123456

123456

123456

123456

123456

123456

123456

123

123

123

12

12

Figure 1

1

1

2

3

4

6

5

7

9

8

10

11

12

Cylinder Dis-Assembly: (Axle Lift Cylinder, Standard)

1.

This is a Tie-Rod construction type cylinder, the four tie-rods

(figure 1 item 6)

and the 8 hex

nuts

(figure 1 item 7)

bolt the cylinder together. When these tie-rods are unbolted the cylinder will

come apart with minimum effort but

DO NOT

unbolt tie-rods until later.

It is recommended

that the

barrel of the cylinder be marked as to which end isthe cylinder rod end and which is the cylinder

base clevis end.

2.

Place the cylinder in a bench vise

(figure 2)

, use pieces of wood or other soft material between

vise jaws and cylinder barrel.

DO NOT

over tighten vise and distort the shape of the barrel, vise

only needs to be tightened enough to hold cylinder.

3.

Place drain pans under cylinder to catch hydraulic oil that may still be in cylinder (

figure 2 Drain

Pans)

. Using ratchet w/ sockets or boxed end wrenches

(repair technicians choice)

remove the

tie-rod hex nuts

(figure 2 item 7).

The tie-rods have a hex nut on each end

(figure 2 item 7)

, not

all the hex nuts will screw off on the same side. The hex nut with the least amount of resistance

is going to screw off. This is OK as the tie-rods can be pulled out from either direction.

4.

When a hex nut has been removed from each tie-rod (it will not matter which end of tie-rod)

pull the tie rods out from the cylinder base and cylinder head

(figure 2 item 6).

There are a total

of 4 tie-rods that will need to be removed

(see figure 3)

.

.