Programming, Programming mill pwr, Operation manual – ACU-RITE MILLPWR Old Style User Manual

Page 26: Programming considerations

PROGRAMMING

MILLPWR

Operation Manual

Page 3-1

PROGRAMMING

Programming Considerations

Depth of Cut

Since the vertical Z-axis is not controlled by a servo motor, you must make changes to

the depth of cut manually.

You don’t have to program the depth, but if you do,

MILLPWR

will preset the

programmed value into the DRO for you. Then, when it’s time,

MILLPWR

will show

you the DRO and ask you to set the depth.

If you are not programming depth, leave it set to 0.

Tool Offset

With

MILLPWR

, you never have to worry about the actual tool path. Because of

MILLPWR

’s tool radius compensation capability, you program only the actual part

dimensions. When you program a line, arc, or frame, use the

TOOL OFFSET

field to tell

MILLPWR

which side of the cut you want the tool to be on.

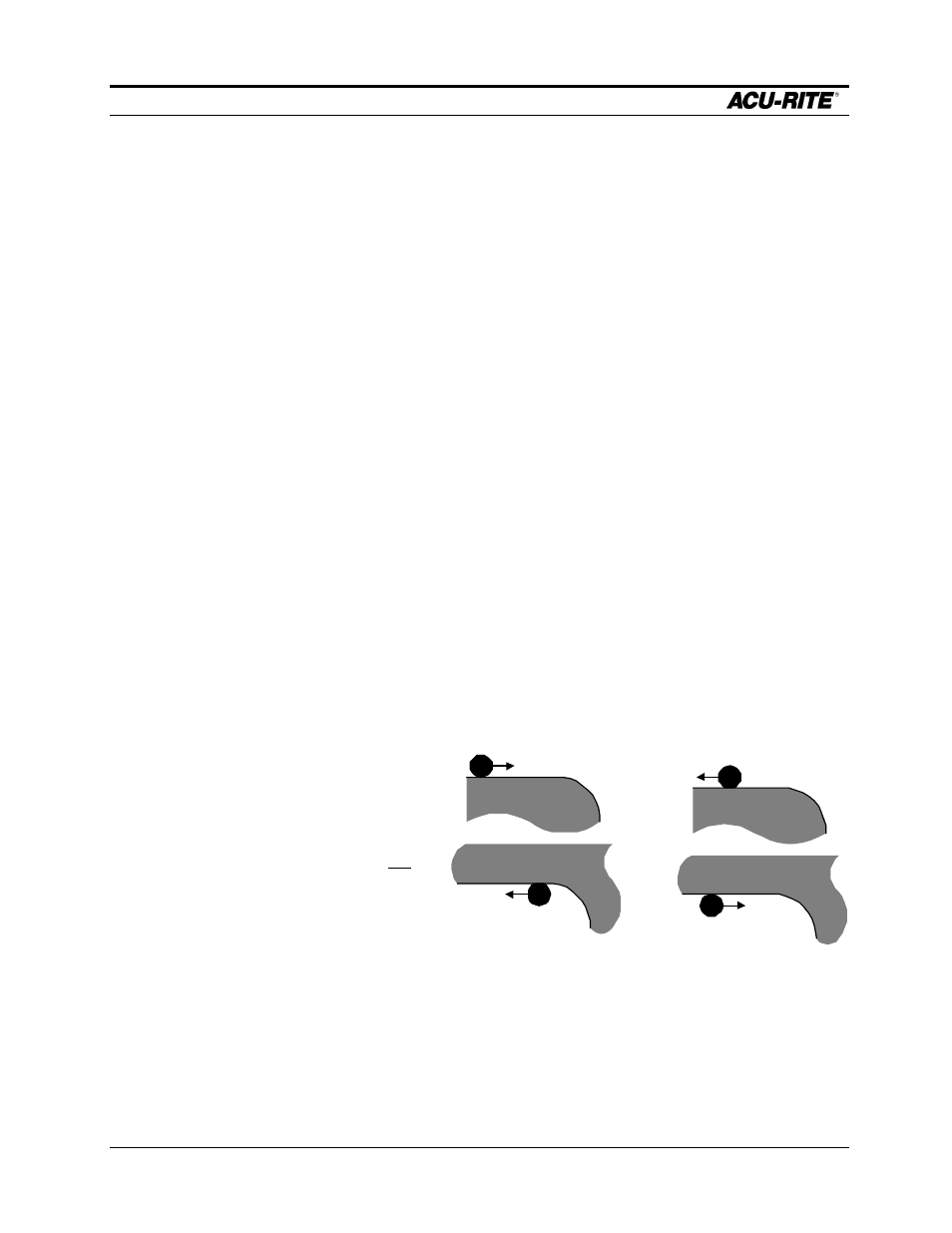

Picture yourself standing behind the tool as it is moving. If the tool is on the left of the

workpiece, use “left” offset. If the tool is to the right of the workpiece, use “right” offset.

By using left and right offsets,

you can program the

dimensions of the part as

found on the blueprint.

MILLPWR

will take care of

all cutter radius

compensation. You do not

have to program the tool

path.

If you use “center” offset, the

programmed dimensions are

for the center of the tool.

For some milling functions, like Frame and Arc, “inside” and “outside” offsets help you

visualize where the tool is.

RIGHT OFFSET

LEFT OFFSET