Troubleshooting guide mill pwr, Operation manual, Symptom – ACU-RITE MILLPWR Old Style User Manual

Page 134: Problem, Recommendation

TROUBLESHOOTING GUIDE

MILLPWR

Operation Manual

Page 9-7

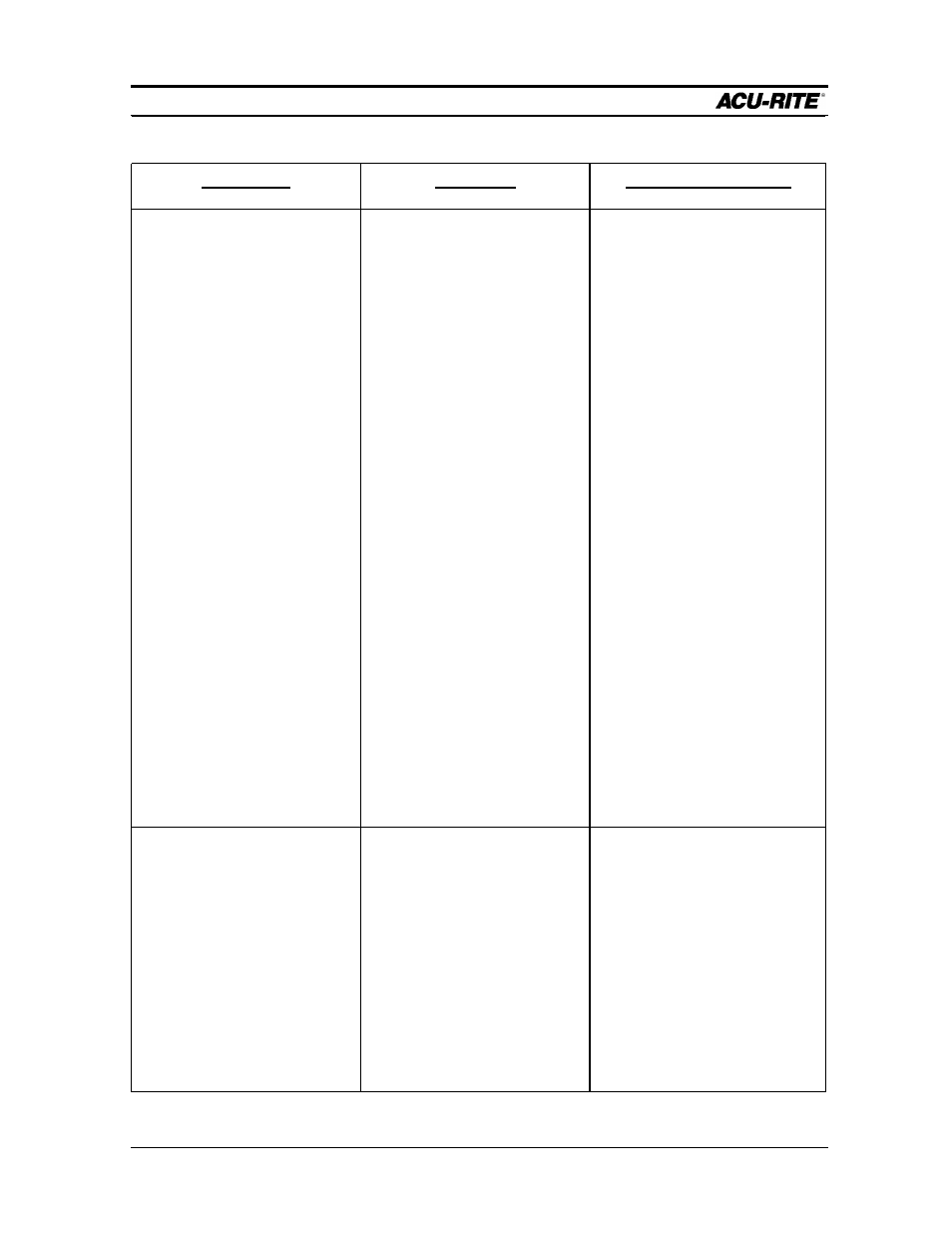

Symptom

Problem

Recommendation

Poor Finish

Dull Tool

Replace the tool.

Incorrect Feeds and/or Speeds

Ensure that the correct feeds and/

or speeds are being used and/or

programmed.

Gibs Out of Adjustment

Refer to the machine tool manual.

Worn Spindle Bearings

Lower the quill full travel with a

sturdy tool in the spindle. Set up a

dial indicator to check move-

ment of the spindle; then move the

tool side-to-side. Total movement

should be within the machine tool

manufacturers’ specifications

between the spindle and the

spindle bearing and between the

quill and the bore. Replace the

spindle bearing if necessary.

Servo Motor Module Out of

Adjustment

Contact your ACU-RITE

MILLPWR Representative.

Also refer to: System not

Repeating or Circles Out of Round.

(p. 9-5)

Screen Flickers

MILLPWR in Screen Saver Mode

MILLPWR not used for approx-

imately 10 minutes. Push any key

on the front panel of the operator’s

console or move any axis to

restore stability to the display

screen.

Should the above recom-

mendation not correct the problem,

contact your ACU-RITE

MILLPWR representative for

repair or replacement procedures.

387900-905 Ed H