Multihop screen – Comtrol UP DeviceMaster User Guide User Manual

Page 135

DeviceMaster UP EtherNet/IP User Guide: 2000424 Rev. L

Chapter 5. Programming the PLC - 135

PLC-5 Typed Write - Set Transmit Produced Sequence Number Message - SLC PLC

5.4.6.11. PLC-5 Typed Write - Set Transmit Produced Sequence Number Message - SLC PLC

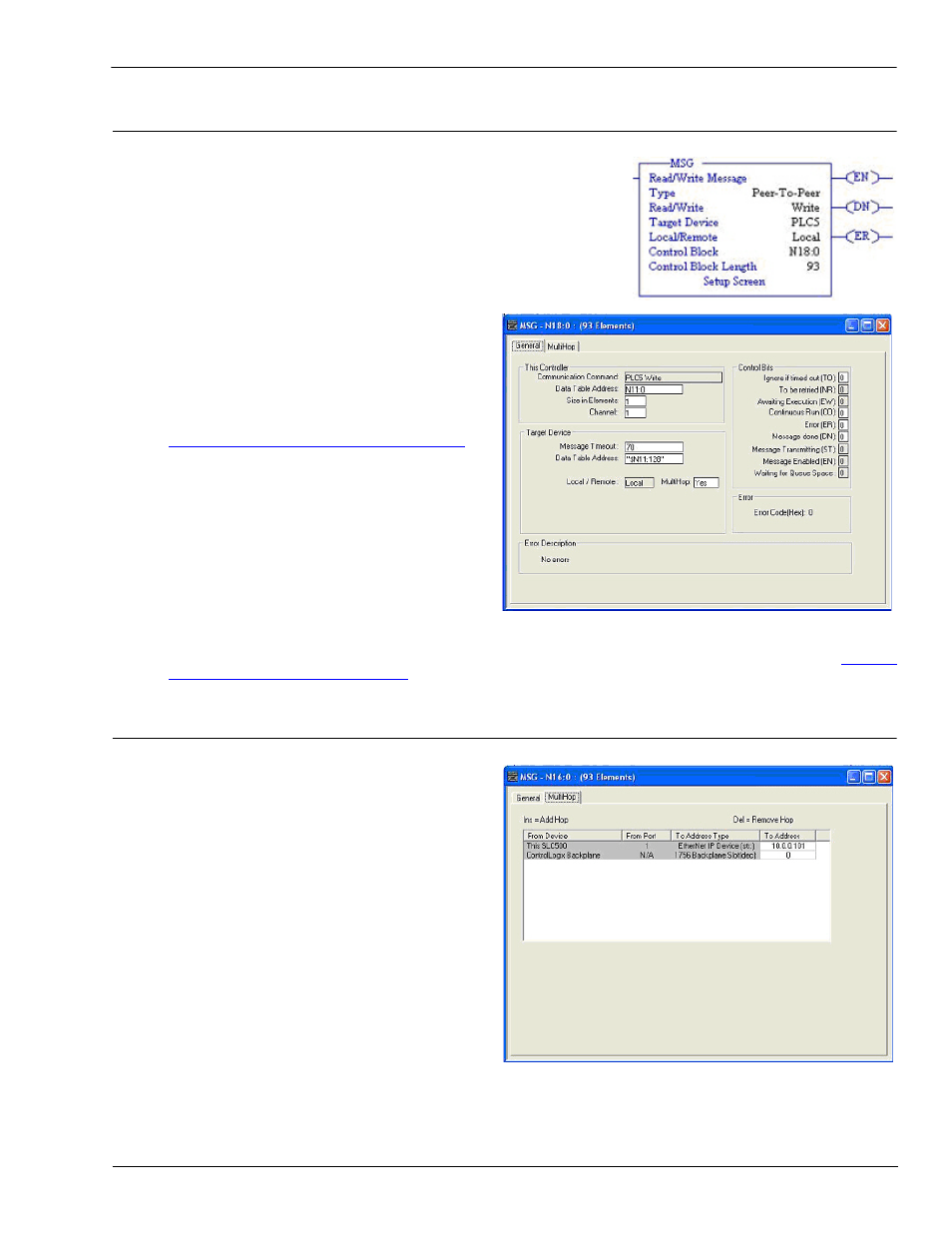

The following screen depicts an PLC-5 Typed Write - Set Transmit

Produced Sequence Number message in ladder logic.

Make the following changes to the ladder logic.

1.

Select the Write option.

2.

Select the PLC5 option.

3.

Select Local.

4.

Assign a dedicated integer file of 93 integers to the Control block.

5.

In the ladder logic, double-click the Setup Screen

in the MSG instruction.

6.

Make the following changes.

a.

Specify the file address where the transmit

sequence number resides in the Data Table

Address box on This Controller panel. For

more information on file addresses, see

2.4.2.1. DeviceMaster UP File Addressing

b.

Type 1 in the Size of Elements box.

c.

Set the Channel parameter to 1 to use the

Ethernet port.

The Message Timeout parameter is not

actually configurable. The RSLogix 500 sets

the value in this box based on the Ethernet

timeout settings.

d.

Specify the port-specific transmit sequence

number file address for the DeviceMaster

UP in the Data Table Address box on the Target Device panel. The transmit sequence number file

address must be specified in logical ASCII format. For more information on file addresses, see

DeviceMaster UP File Addressing

e.

Set the MultiHop option to Yes.

5.4.6.12. MultiHop Screen

1.

Select the MultiHop tab on the MSG dialog.

2.

Make the following changes.

a.

Type the IP address for the DeviceMaster

UP (the designated EtherNet/IP Device) in

the To Address box.

b.

Type 0 (zero) in the To Address box for the

ControlLogix Backplane.

Note: If you are using an SLC 5/03 or SLC 5/04

with an EtherNet/IP sidecar, you may need

to add Hops to route the message on your

PLC.