1 flexible inspection loading – Banner PresencePLUS P4 COLOR Series User Manual

Page 42

5.4.1 Flexible Inspection Loading

Release 2009R1B introduces a more flexible inspection loading capability that allows most inspections created by any

PresencePLUS vision sensor to be loaded through the PresencePLUS software even if connected to a different type

of PresencePLUS vision sensor. This means that you can now load, for example, an inspection created by an OMNI

1.3 into PresencePLUS software connected to a standard OMNI. Prior to Release 2009R1B, inspections could only

be loaded into PresencePLUS software that was connected to the same type of PresencePLUS vision sensor that had

created the inspection. In other words, a ProII camera could only load inspections created by another ProII camera,

and an OMNI could only load an inspection saved from another OMNI, etc.

Note: The one limitation that still exists occurs when trying to load an inspection that uses a tool that is unavailable

(or unlicensed) for the currently connected sensor (for example, attempting to load to an inspection that uses a

Geometric Count tool to a PresencePLUS AREA sensor will not work because the Geometric Count tool is not

supported on the AREA sensor).

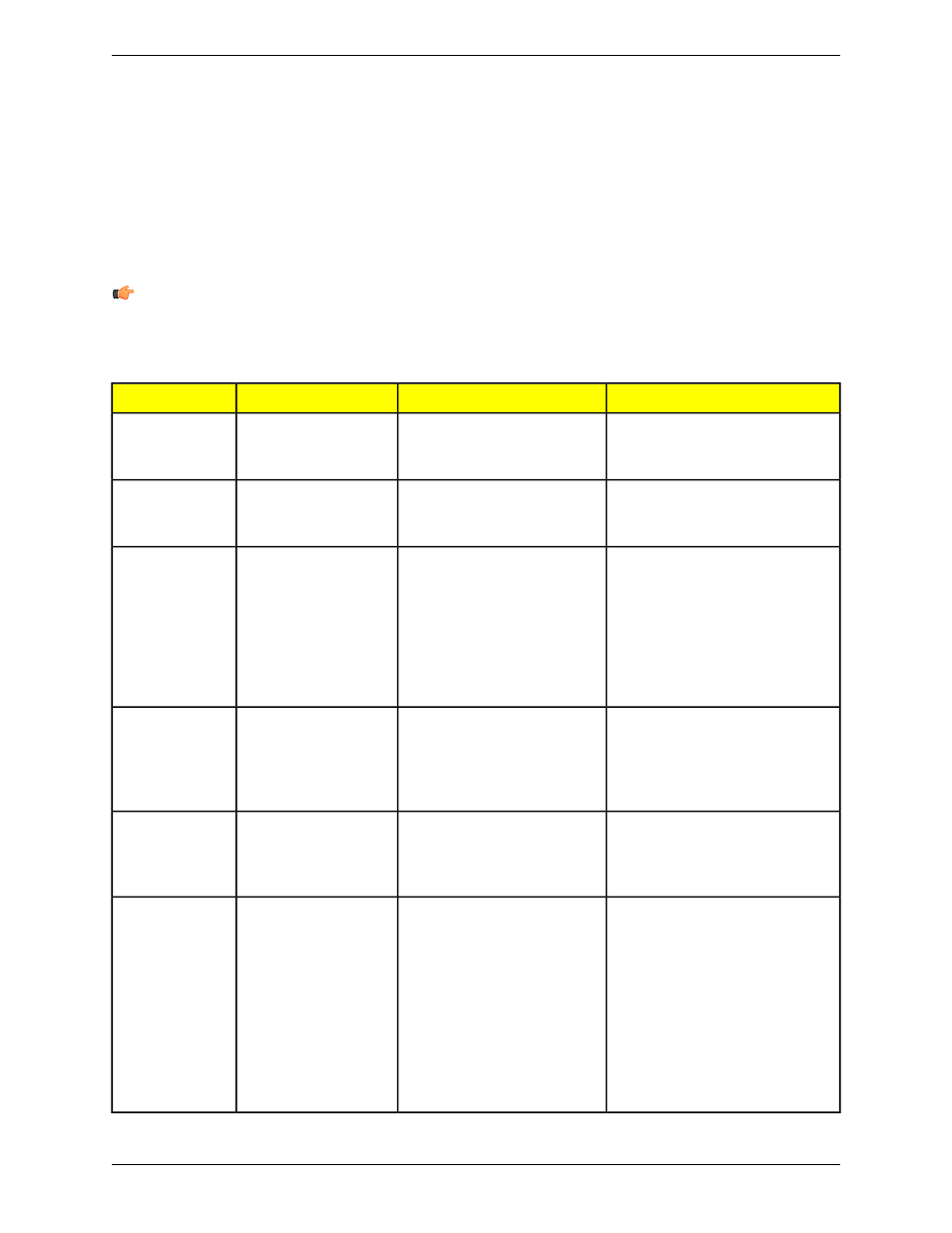

Possible Inspection Modifications

Result

Inspection Destination

Inspection Source

None required

A dialog indicates that the image

color has changed and the

inspection loads

Standard grayscale

sensor (for example, a

standard OMNI)

Color sensor (for

example, a Color

OMNI)

None required

A dialog indicates that the image

color has changed and the

inspection loads

Color sensor (for

example, a Color OMNI)

Grayscale sensor

(for example, a

standard OMNI)

Reposition image, adjust ROIs and

tools in the FOV, and possibly

acquire a new reference image

A dialog indicates that the

image/FOV has been adjusted

and the image loads the image

into the upper-left of the FOV.

Standard VGA sensor

(for example, a standard

AREA sensor)

High Resolution

(1.3) sensor (for

example, an

AREA 1.3 sensor

)

Note that the image may be

cropped at the right and/or

bottom and ROIs may be outside

the image area

Possibly acquire a new reference

image

A dialog indicates that the FOV

has been adjusted and the

inspection loads with the image

centered in the FOV

High Resolution (1.3)

sensor (for example, an

AREA 1.3 sensor)

Standard VGA

sensor (for

example, a

standard AREA

sensor)

Adjust I/O as appropriate

A dialog indicates that the

inspection uses I/Os not

Sensor with 4 I/O (for

example, an OMNI)

Sensor with 6 I/O

(for example, a

ProII)

available on the sensor and the

inspection loads

Retest and modify timings as

appropriate, and possibly acquire a

new reference image

A dialog indicates that the timing

was adjusted and the inspection

loads with the timing(s) adjusted

to the maximum time allowed on

that sensor

Sensor that supports a

smaller maximum trigger

delay, trigger width,

NTSC fail/hold time, or

exposure time (for

example, a standard

Sensor that

supports a larger

maximum trigger

delay, trigger

width, NTSC

fail/hold time, or

OMNI maximum trigger

delay set to 8000 ms)

exposure time (for

example, a ProII

maximum trigger

delay set to 10000

ms)

Banner Engineering Corp.

Minneapolis, MN USA

42

2/2010

Tools Screen