Interpreting status indicators, Error codes – Rockwell Automation 2093-xxxx Kinetix 2000 Multi-axis Servo Drive User Manual User Manual

Page 134

Publication 2093-UM001A-EN-P — March 2007

134

Troubleshooting the Kinetix 2000 Drive System

Interpreting Status

Indicators

Use these troubleshooting tables to identify faults, potential causes, and the

appropriate actions to resolve the fault. If the fault persists after attempting to

troubleshoot the system, please contact your Rockwell Automation sales

representative for further assistance.

Error Codes

The following list of problematic symptoms (no error code shown) and faults

with assigned error codes is designed to help you resolve anomalies.

When a fault is detected, the seven-segment LED indicator will display an E

followed by the flashing of the two-digit error code, one digit at a time. This is

repeated until the error code is cleared.

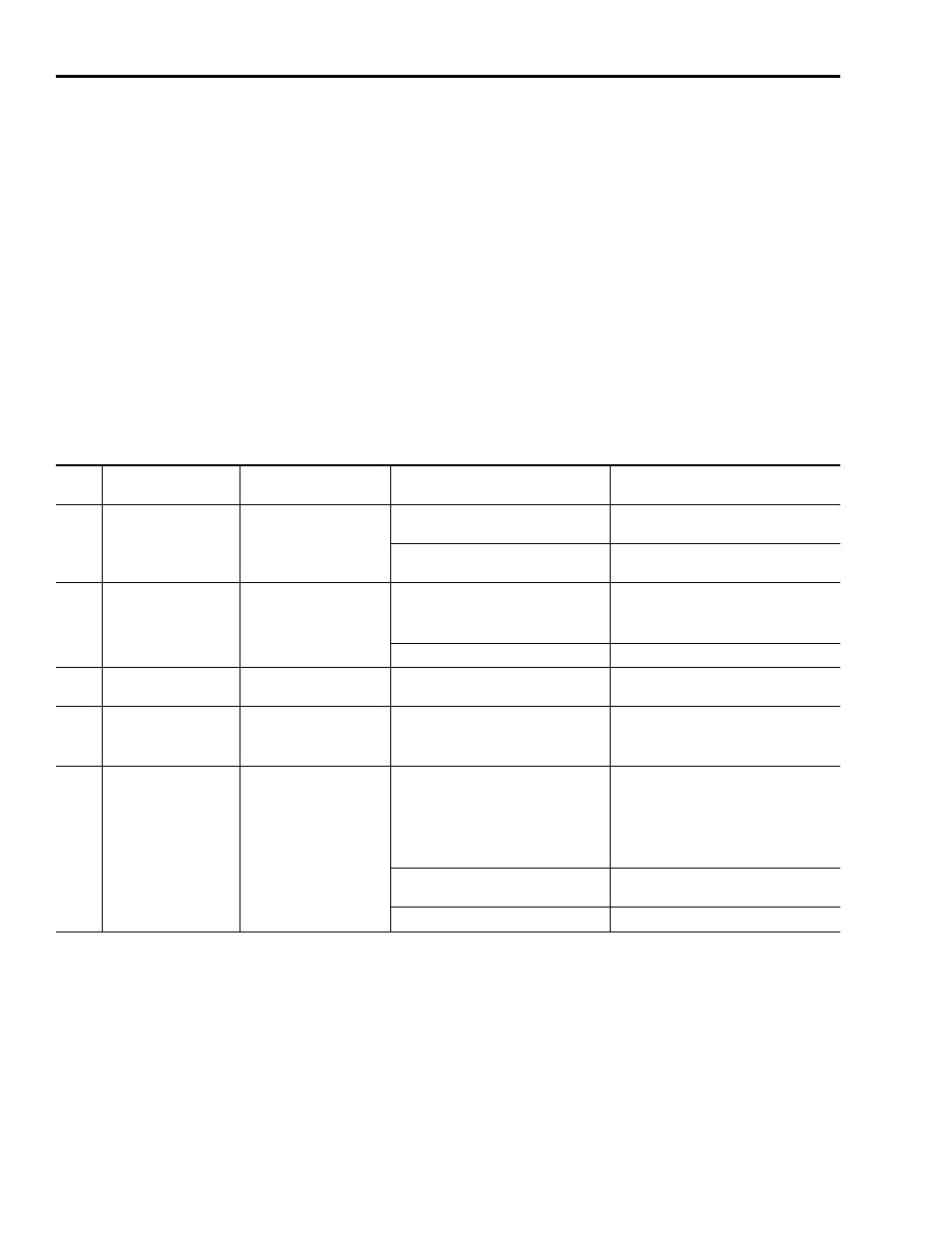

Seven-segment LED Indicator Error Codes

Error

Code

Fault Message

RSLogix (HIM)

Problem or Symptom

Potential Cause

Possible Resolution

Power (PWR) indicator not

ON

No ac power or auxiliary logic power.

Verify ac control power is applied to the

Kinetix 2000 system.

Internal power supply malfunction.

Call your Rockwell Automation sales

representative to return module for repair.

Motor jumps when first

enabled

Motor wiring error.

• Check motor wiring.

• Run Hookup test in RSLogix 5000

software.

Incorrect motor chosen.

Verify the proper motor is selected.

Digital I/O not working

correctly

I/O power supply disconnected.

Verify connections and I/O power source.

E00

BusUndervoltage

Fault

(Blown fuse)

A blown fuse was detected

on the inverter PCB

Blown fuse.

Call your Rockwell Automation sales

representative to return module for repair.

E04

MotorOvertemp

Fault

(Motor Overtemp)

Motor thermal switch

tripped

High ambient motor temperature and/or

excessive current

• Operate within (not above) the

continuous torque rating for the

ambient temperature

40 °C (104 °F) maximum.

• Lower ambient temperature, increase

motor cooling.

Motor wiring error.

Check motor wiring at MF connector on the

IAM/AM.

Incorrect motor selection.

Verify the proper motor has been selected.