Iout signal generation, J2 breakout board assembly – european union, Emc compliance – Rockwell Automation 1398-DDM-xxx ULTRA 100 Series Drives Installation Manual User Manual

Page 82: Motor encoder output signal, Motor encoder output specifications

Publication 1398-5.2 – PDF 1997

6-18

Interfaces

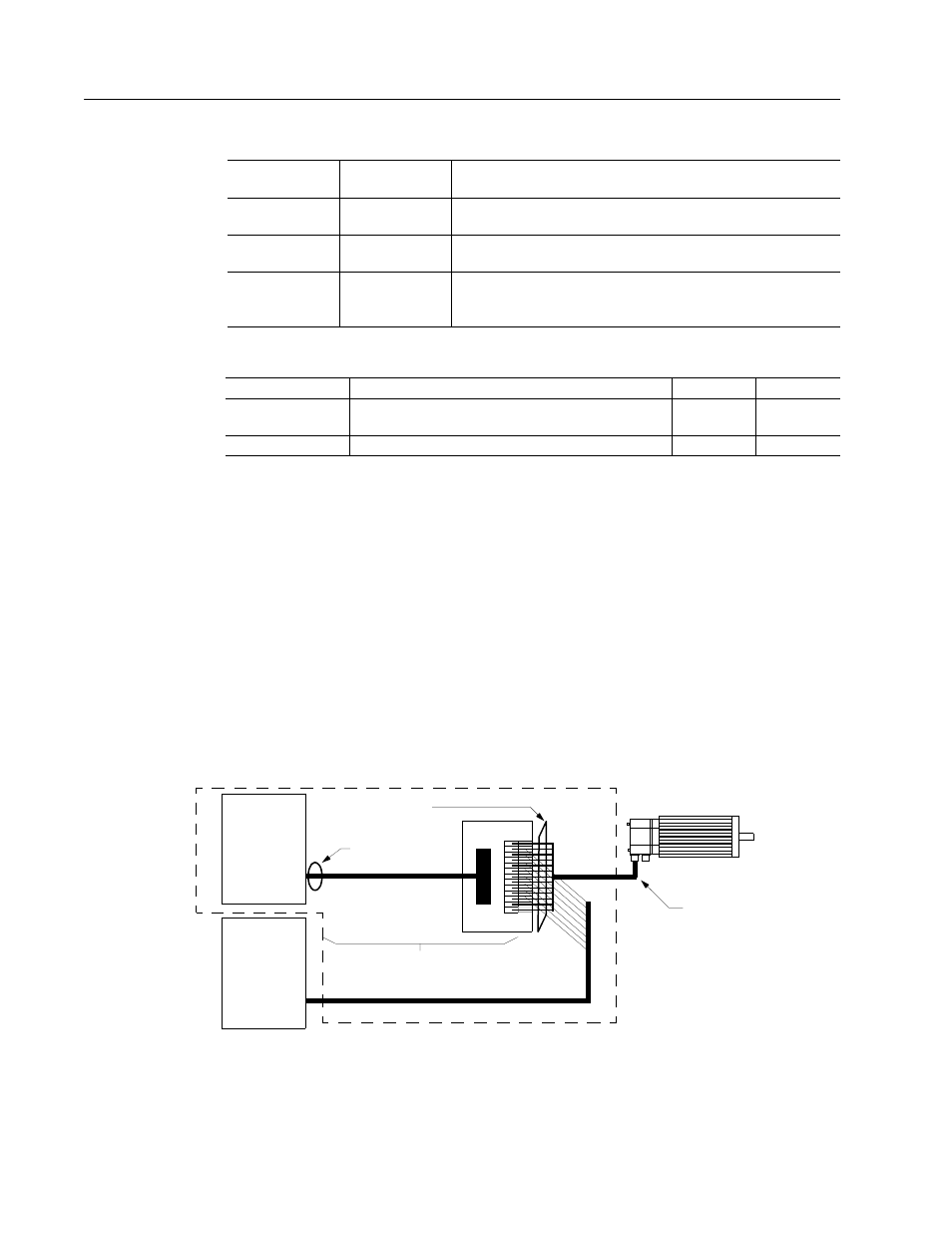

IOUT Signal Generation

The Index output signal (IOUT) is not synchronized to a particular

state of the A and B output signals (AOUT and BOUT). Some

controllers, such as those used in the CNC industry, use the condition

I=1, A=1, B=1 to indicate a home position. In such applications the

encoder outputs from the drive cannot be used, since it cannot be

guaranteed that the IOUT signal will be active during the state

AOUT=1, BOUT=1. Instead, the unbuffered motor encoder signals

can be used as shown in Figure 6.22. The J2 Breakout Board assembly

connects the motor encoder signals directly to the position feedback of

the controller.

Table 6.17:

Motor Encoder Output Signal

Analog Out-

put

Pin Number

Description

AOUT (+)

AOUT (-)

J1-7 (+)

J1-8 (-)

Motor Output Channels A(+) and A(-). Differential TTL levels

from line driver. Signal resolution is selectable.

BOUT (+)

BOUT (-)

J1-9 (+)

J1-10 (-)

Motor Output Channels B(+) and B(-). Differential TTL levels

from line driver. Signal resolution is selectable.

IOUT (+)

IOUT (-)

J1-11 (+)

J1-12 (-)

Motor Output Channels I(+) and I(-). Differential TTL levels

from line driver. Output pulse occurs once per motor shaft

revolution.

Table 6.18:

Motor Encoder Output Specifications

Parameter

Description

Minimum

Maximum

Differential Out-

put Voltage

Voltage measured between the (+) and (-) pins

with R

L

= 100 Ohm.

2.0 Volts

Output Current

Current flowing out of the (+) or (-) pin.

-20 mA

+20 mA

Figure 6.22

J2 Breakout Board Assembly – European Union

EMC Compliance

Drive

Controller

J2

A,B,I

J2 Breakout Board Assembly

P/N 9101-1392

Pigtailed Motor

Encoder Cable

Grounded Metal Enclosure*

230Ohm @ 100MHz

Ferrite Toroid*

215Ohm @ 100MHz

Ferrite Clamp*

NOTE:

An asterik (*) indicates an installation option to comply with EU EMC Directives. Either

a grounded metal enclosure or ferrite cores provide the requisite EMC protection.