Example of custom motor file creation, Manufacturer's data, Parameter conversions – Rockwell Automation 1398-DDM-xxx ULTRA 100 Series Drives Installation Manual User Manual

Page 270: Manufacturer’s data

Publication 1398-5.2 – PDF 1997

D-16

Creating Custom Motor Files

Example of Custom Motor

File Creation

The following is an example of a custom motor. A 50:1 gear is

included inside this motor. The example illustrates how to configure a

custom motor.

Manufacturer’s Data

The following specifications were taken from the manufacturer’s data

sheet:

●

Reduction Ratio = 1:50

●

Rated Current = 1.4 Amp

●

Maximum Current = 3.8 Amp

●

Maximum Speed = 80 RPM

●

Torque Constant = 270 in-lb/Amp

●

BEMF = 1.1 Volt/RPM per phase

●

Motor Resistance = 3.7

Ω

per phase

●

Motor Inductance = 5.0mH per phase

●

Thermal Time Constant = 30 minutes

●

Moment of Inertia = 5.1 in-lb-sec

2

●

Encoder Linecount = 1500 lines/rev

●

No Integral Thermostat

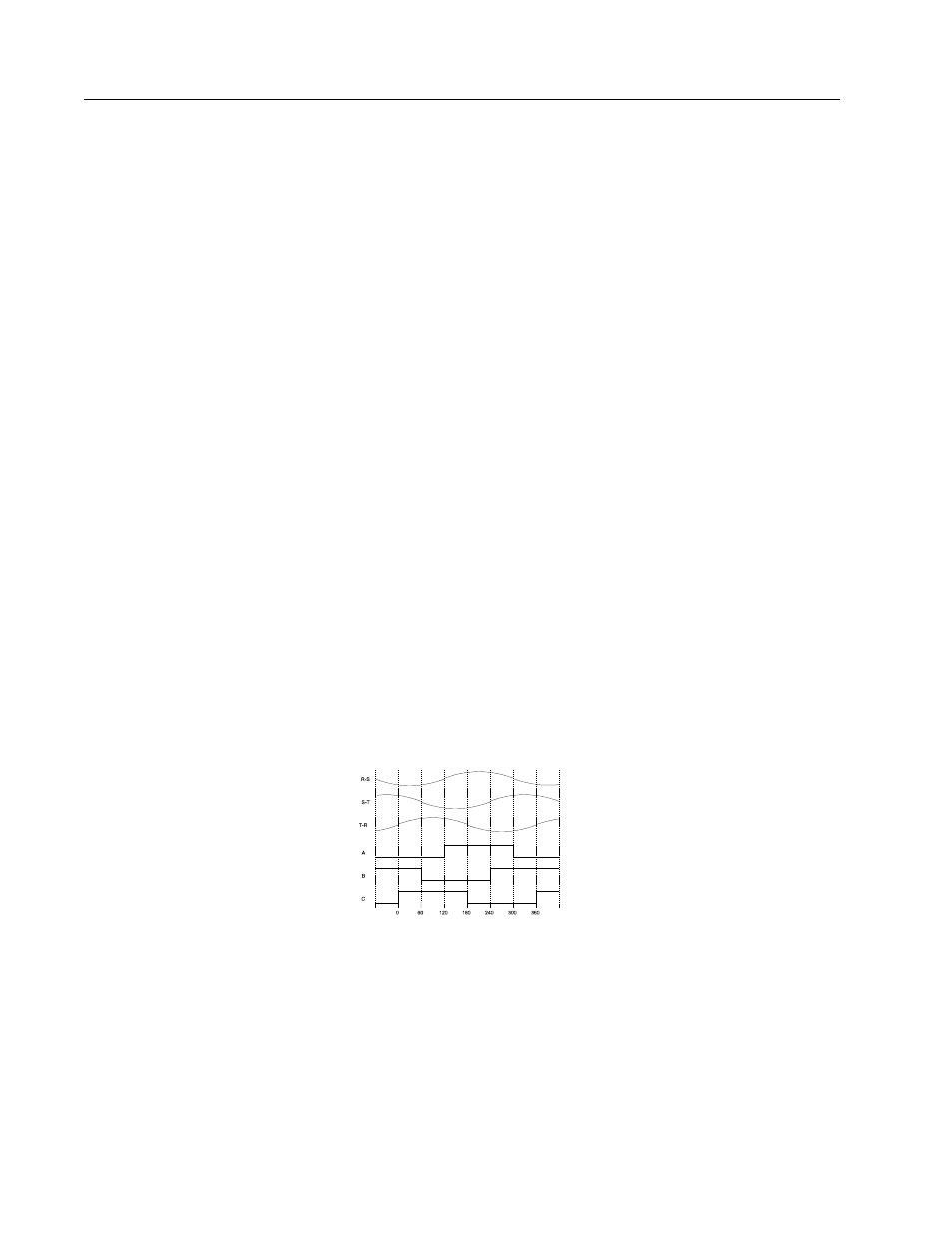

A check with the manufacturer yielded that the motor has 8 poles, and

that the line-to-line back-EMF and Hall signals are as shown in

Figure D.7. The figure indicates that no lead swapping is necessary

but the Hall offset is 120

o

.

Parameter Conversions

The 1:50 gearing makes this motor an unusual case. The motor file

must be generated as if the motor and gear are two separate devices.

The inertia, torque, speed, etc., must be computed based on the motor

side of the gearing, rather than the load side.

The maximum speed of the motor, before gearing, is computed as:

The torque constant of the motor, before gearing, is computed as:

Figure D.7

Back-EMF and Hall Signals, Clockwise Rotation

Intro