1 fundamentals of positioning, Position encoders and reference marks – ACU-RITE CNC 3500i User Manual

Page 52

26

2 Machining Fundamentals

2.1 F

u

ndamentals of P

o

sitioning

2.1 Fundamentals of Positioning

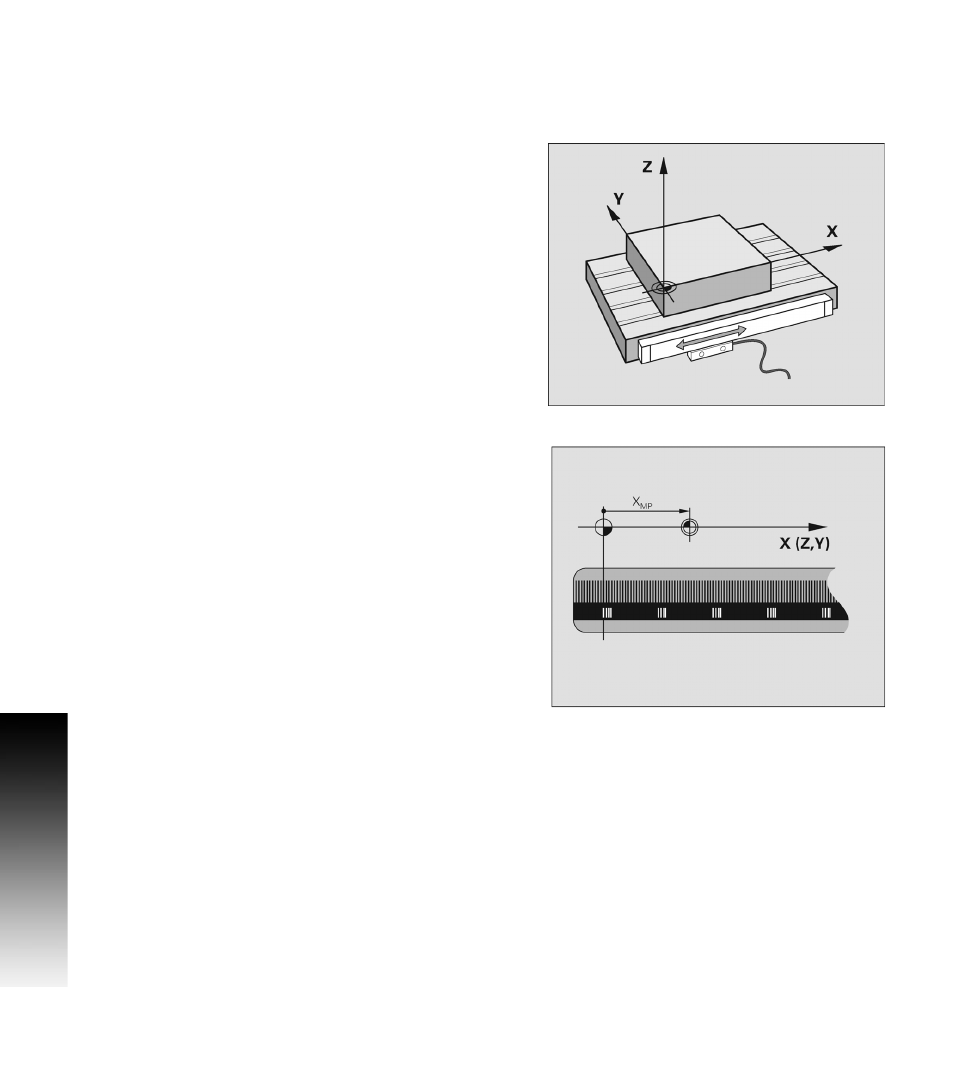

Position encoders and reference marks

The machine axes are equipped with position encoders that register

the positions of the machine table or tool. Linear axes are usually

equipped with linear encoders, rotary tables and tilting axes with angle

encoders.

When a machine axis moves, the corresponding position encoder

generates an electrical signal. The CNC evaluates this signal and

calculates the precise actual position of the machine axis.

If there is a power interruption, the calculated position will no longer

correspond to the actual position of the machine slide. To recover this

association, incremental position encoders are provided with

reference marks. The scales of the position encoders contain one or

more reference marks that transmit a signal to the CNC when they are

crossed over. From that signal the CNC can re-establish the

assignment of displayed positions to machine positions. For linear

encoders with distance-coded reference marks the machine axes

need to move by no more than 20 mm, for angle encoders by no more

than 20°.

With absolute encoders, an absolute position value is transmitted to

the control immediately upon switch-on. In this way the assignment

of the actual position to the machine slide position is re-established

directly after switch-on.