Face mill cycle – ACU-RITE CNC 3500i User Manual

Page 187

ACU-RITE 3500i

161

7.

2

C

a

n

n

e

d

C

y

c

le

s

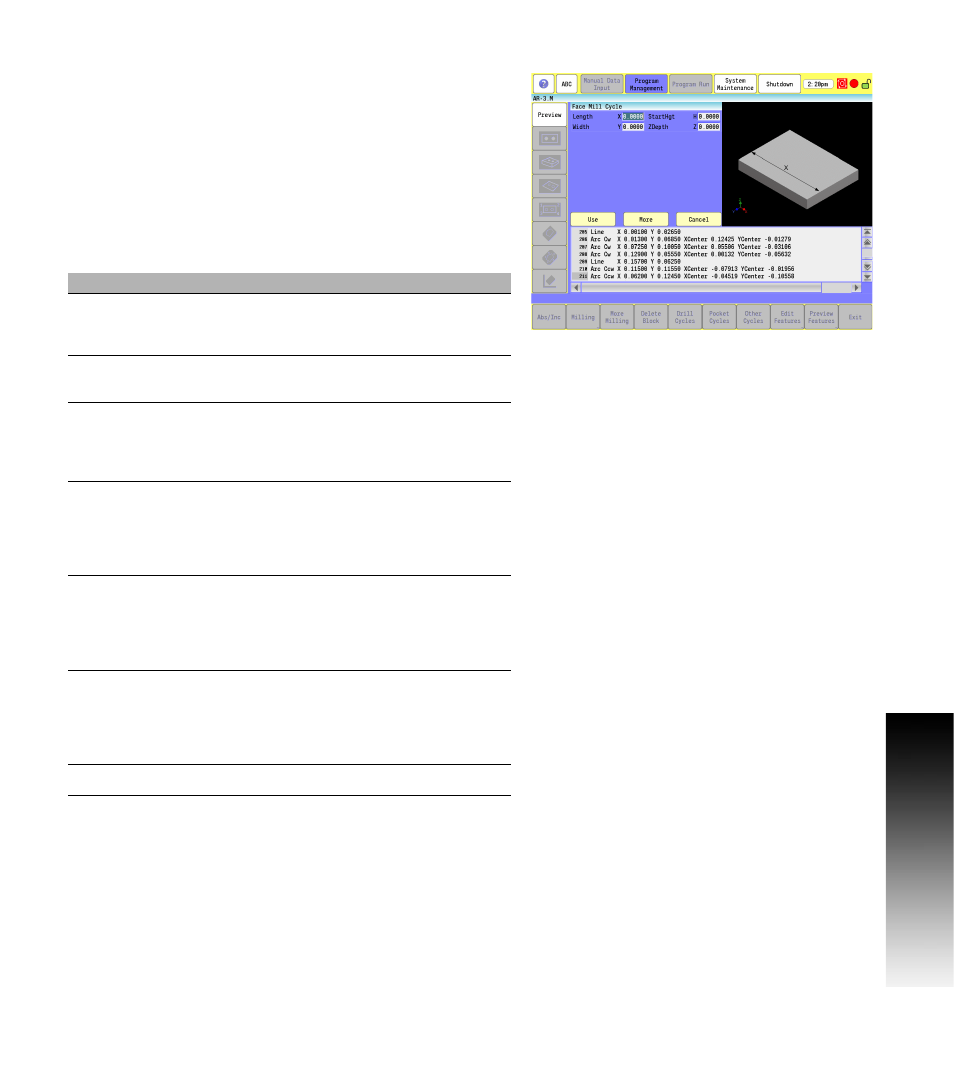

Face Mill Cycle

Facing cycles simplify the programming required to face the surface

of a part.

Execution begins one tool radius from the D and E (start point). The

selected stepover determines the approach axes.

Facing cycles can start in any corner of the surface and cut in any

direction, depending on the sign (+/-) of the X (Length) and A (Width)

values. Program a slightly oversized X and A to ensure complete

facing of the surface.

At the end of the cycle, the tool rapids to H, then rapids back to D and

E (start position).

Field

Code

Description

Length

X

The feedrate at which the tool will "ramp"

into the pocket in all three axes. Default is

last programmed feedrate.

Width

Y

Feedrate used during finish passes. Default

is last programmed feedrate.

StartHgt

H

The Absolute Z position before beginning

the facing cycle. This must be 0.1” (or 2

mm) above the surface. Executed in rapid.

(Required)

ZDepth

Z

Absolute depth of the finished surface.

(Required)

NOTE: ZDepth must be lower than

StartHgt. StartHgt is 0.1” (2.0 mm) above

the work surface.

XStepOver

A

Width of cut in the X-axis direction. When

you do not enter a value, the CNC defaults

to 70% of the active tool radius. Maximum

step-over permitted is 70% of the active

tool radius.

YStepOver

B

Width of cut in the Y-axis direction. When

you do not enter a value, the CNC defaults

to 70% of the active tool radius. Maximum

stepover permitted is 70% of the active tool

radius.

Feed

F

Feedrate used in cycle.