Manual tool diameter measure for special tools, 3 pr obing cy cles – ACU-RITE CNC 3500i User Manual

Page 239

ACU-RITE 3500i

213

7.

3 Pr

obing Cy

cles

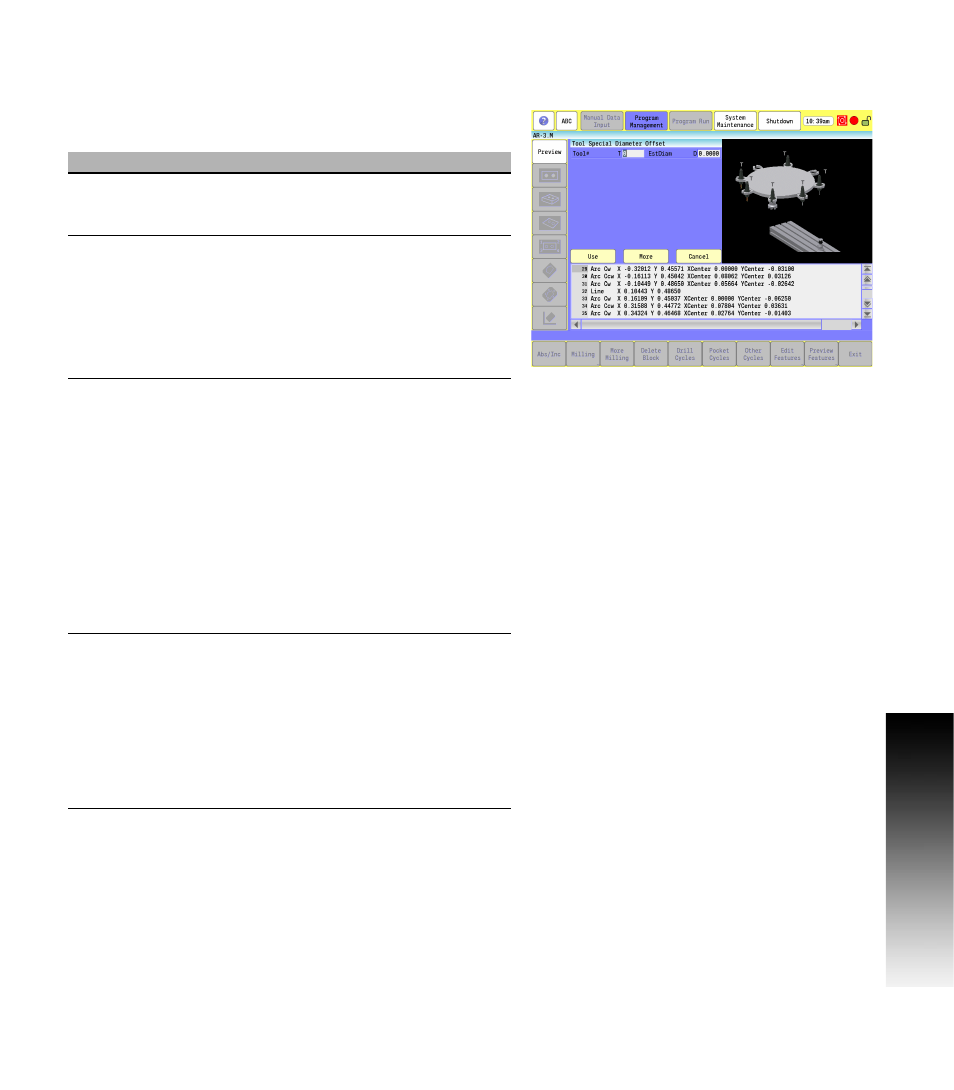

Manual Tool Diameter Measure for Special Tools

Updates tool diameter register for irregular shaped tools or tools

with a hole in the center of the bottom.

This cycle is used to measure the diameter of irregularly shaped tools

or tools with a hole in the center of the bottom.

Field

Code

Description

Tool#

T

Tool number. (Required)

The T cycle parameter must be the same as

the current tool in the spindle.

EstDiam

D

This is the rough diameter of the tool.

(Required) The diameter specified in this

cycle parameter should be larger than the

actual diameter of the tool being measured

but no more than 0.04" (1.0 mm) over. If

you have a left-handed tool, you would give

a negative value to the diameter so the

spindle turns on in the forward direction.

DistDown

E

The incremental distance from the current

Z Retract amount to go down along the side

of the probe stylus when doing a diameter

pick. The maximum E value is 0.55" (13.97

mm) or the tool may crash into the probe or

table. If you enter a value larger than 0.55"

(13.97 mm), the control issues an error

message. If E is not set, the cycle uses a

default value of 0.1" (2.54 mm). (Optional)

[Default: 0.1"]

Ball nose cutters and special cutters that

require a move down more than 0.55"

(13.97 mm) are not supported.

NOTE: Z Retract Amount is set in the Tool

Probe Parameters.

OvrMed

Feed

M

This is the override for the medium

feedrate that was set in the machine setup

parameter ZFirstPickFeedRate_Medium.

Sometimes there may be a tool that has a

large diameter making it necessary to slow

it down to prevent the touch probe from

being hit too hard. This can only be set

slower. Trying to set this higher will result

in the software using the original feedrate.

(Optional)