Tool definition and activation, 1 explaining basic cy cles – ACU-RITE CNC 3500i User Manual

Page 172

146

7 Programming: Canned Cycles, sub-programs

7.

1 Explaining Basic Cy

cles

Tool Definition and Activation

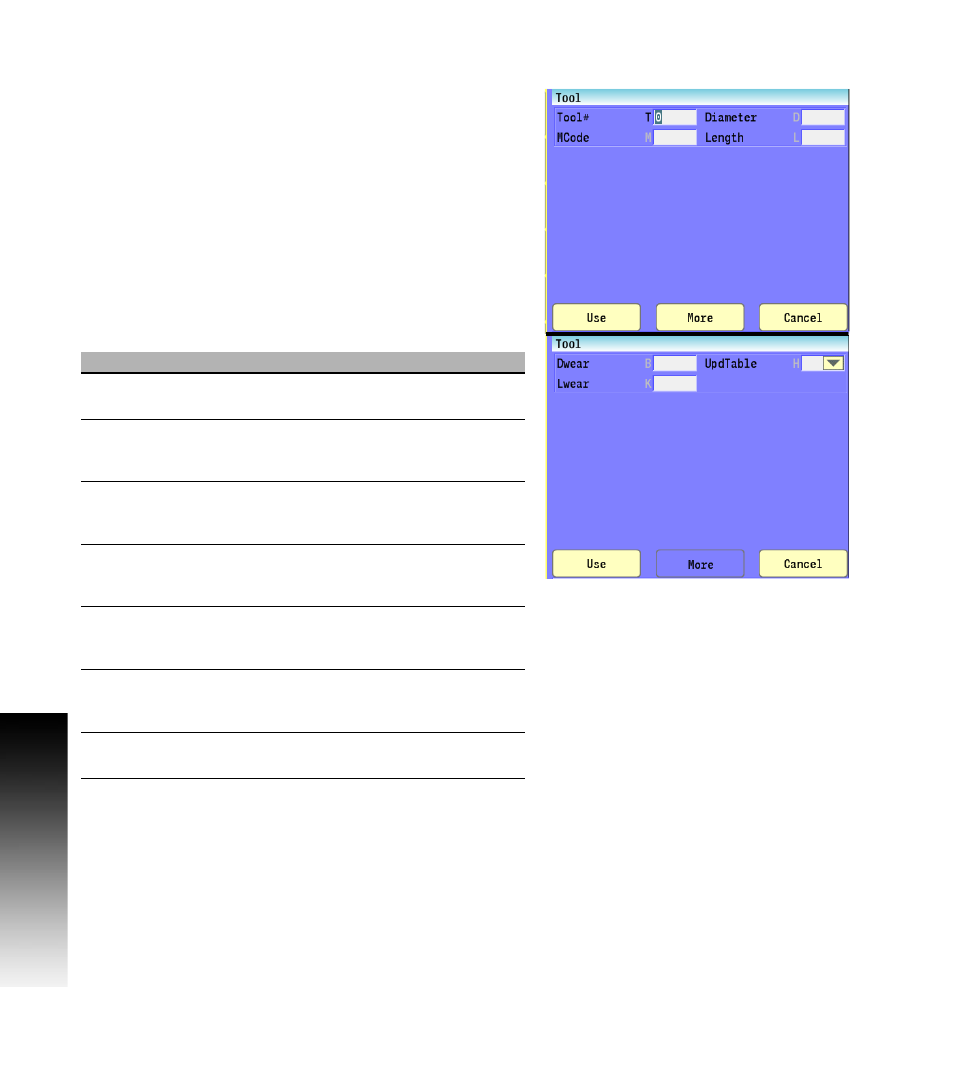

Use the Tool command to define and/or use a tool in the program. On

a machine with a fixed bin tool changer, a Tool call will always mount

the tool, with no need for the MCode 6. On a machine with a random

bin tool changer, the MCode 6 is required in order to mount the tool.

On a random type system, a Tool call without the MCode 6 will define

the tool using the specified parameters, and pre-fetch the tool by

indexing the random bin magazine to that tool's bin, but will not mount

the tool. Refer to chapter 4 "Tool Management" on page 59 for

additional information regarding tools, tool diameter and length

offsets, tool life management, tool radius compensation, and the Tool

Table.

Conversational format: Tool#

G-code format: T[n]

Field

Code

Description

Tool#

T

The number of the desired miscellaneous

machine code to be activated. (Required)

MCode

M

The number of the desired M-Code to

activate, typically MCode 6, for mounting

the tool.

Diameter

D

The diameter measurement of the tool to

be used, overriding the values in the Tool

Table.

Length

L

The length measurement of the tool to be

used, overriding the values in the Tool

Table.

Dwear

B

The amount of wear to compensate for in

the diameter of the tool to be used,

overriding the values in the Tool Table.

Lwear

K

The amount of wear to compensate for in

the length of the tool to be used, overriding

the values in the Tool Table.

Updtable

H

Select Yes to permanently write/overwrite

the values specified to the Tool Table.