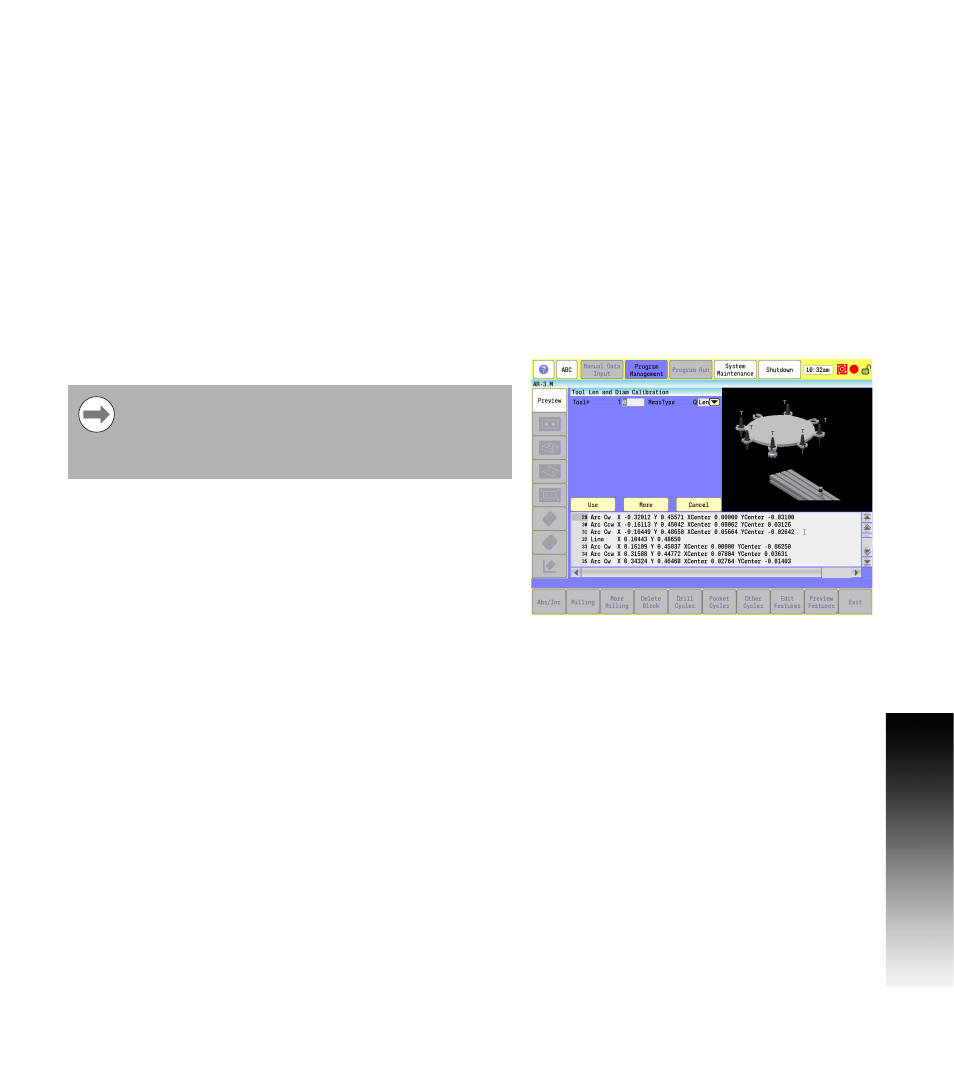

Tool length and diameter offset preset, 3 pr obing cy cles – ACU-RITE CNC 3500i User Manual

Page 229

ACU-RITE 3500i

203

7.

3 Pr

obing Cy

cles

The Z-axis then does a guarded Z move down 0.1" (2.54 mm) or

whatever amount was placed in the E cycle parameter and then

moves over toward the probe stylus 0.3" (7.62 mm) or until it

touches the probe stylus. If contact is not made with the probe or if

contact is made during a guarded move, then an alarm is generated

and the canned cycle terminates.

After the probe stylus is touched on the first side, the machine then

rapids up and over the stylus, then down on the opposite side, then

over to the other two sides until it has touched the probe stylus on

all four quadrants. This establishes the center of the probe stylus.

The spindle then turns off and the machine touches off on two sides

of the probe with the spindle off finding the effective probe stylus

diameter. Then, rapids up above the probe stylus and over to the

center.

Remove the calibration standard. You are now ready to start running

the G151 to set your tool-length offsets or tool diameter registers.

Tool Length and Diameter Offset Preset

Updates length and diameter tool registers.

Each tool must have the length set once before trying to set the

diameter. Call this cycle up the first time using Q2 because it

automatically sets the length first then the diameter.

Calibrate the tool probe at least once before trying to automatically

preset a tool. This is done initially, but if the stylus is ever changed

or the probe is moved, then you must again calibrate the tool probe

This tool preset (G151) can be run from within a program or from the

Manual Data Input Mode with G-code MDI selected.

If the tool has a hole on the bottom so that the probe

would fall between the tool teeth, do not use this cycle.

Damage to the probe could result. In this case, use G152

for manual length preset or G153 for manual diameter

preset.