IAI America RCP2-CF User Manual

Page 92

72

The relationships of movement command inputs/position complete outputs and corresponding position numbers

are shown below.

For easier identification, each input/output signal has a name similar to the naming convention used with air

cylinders.

However, note that the target position is determined by the value set in the [Target position] field under each

position number. Therefore, changing the magnitude correlation of the settings in Nos. 0 to 3 will change the

meanings of the corresponding input/output signals.

Accordingly, the settings in the respective position numbers should match the semantic meanings of the

corresponding signal names used in this operation manual, unless doing so will pose a problem.

Input signal

Output signal Target

position

Rear end move (ST0)

Rear end complete (PE0)

Setting in the [Target position] field under

position No. 0

Example: 5 mm

Front end move (ST1)

Front end complete (PE1)

Setting in the [Target position] field under

position No. 1

Example: 390 mm

Intermediate point 1 move (ST2) Intermediate point 1 complete (PE2)

Setting in the [Target position] field under

position No. 2

Example: 100 mm

Intermediate point 2 move (ST3) Intermediate point 2 complete (PE3)

Setting in the [Target position] field under

position No. 3

Example: 250 mm

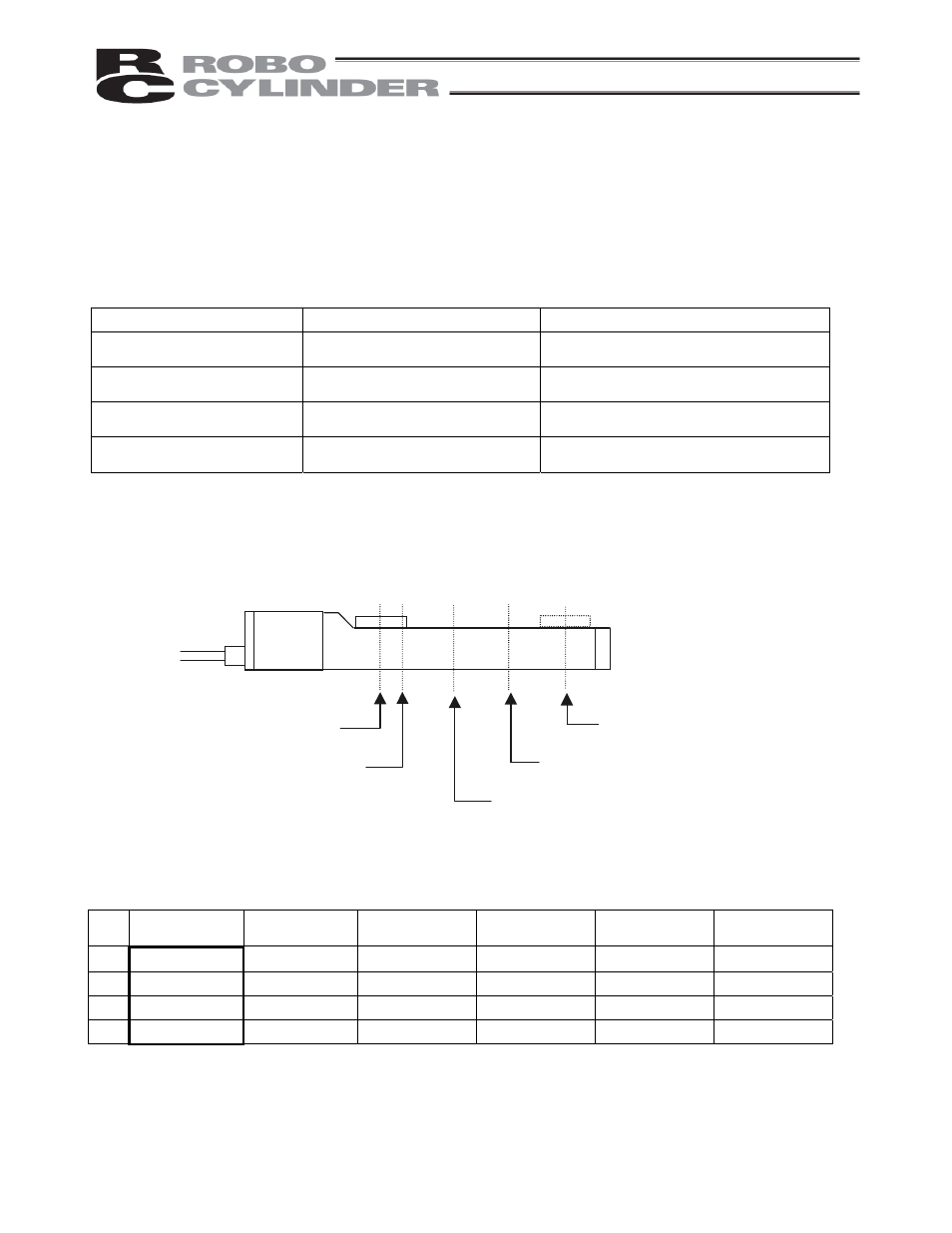

Positioning relationship on the ROBO Cylinder

An example of a slider type with a stroke of 400 mm is explained.

[Motor side]

[Counter-motor side]

Position table (Enter in the fields indicated in bold)

No. Position

Speed

Acceleration/

deceleration

Push

Positioning

band

Acceleration

only MAX

0

5 500

0.3 0 0.1 0

1

390

500

0.3 0 0.1 0

2

100

500

0.3 0 0.1 0

3

250

500

0.3 0 0.1 0

Home position (0 mm)

Rear end complete (5 mm)

Front end complete (390 mm)

Intermediate point 2 complete (250 mm)

Intermediate point 1 complete (100 mm)