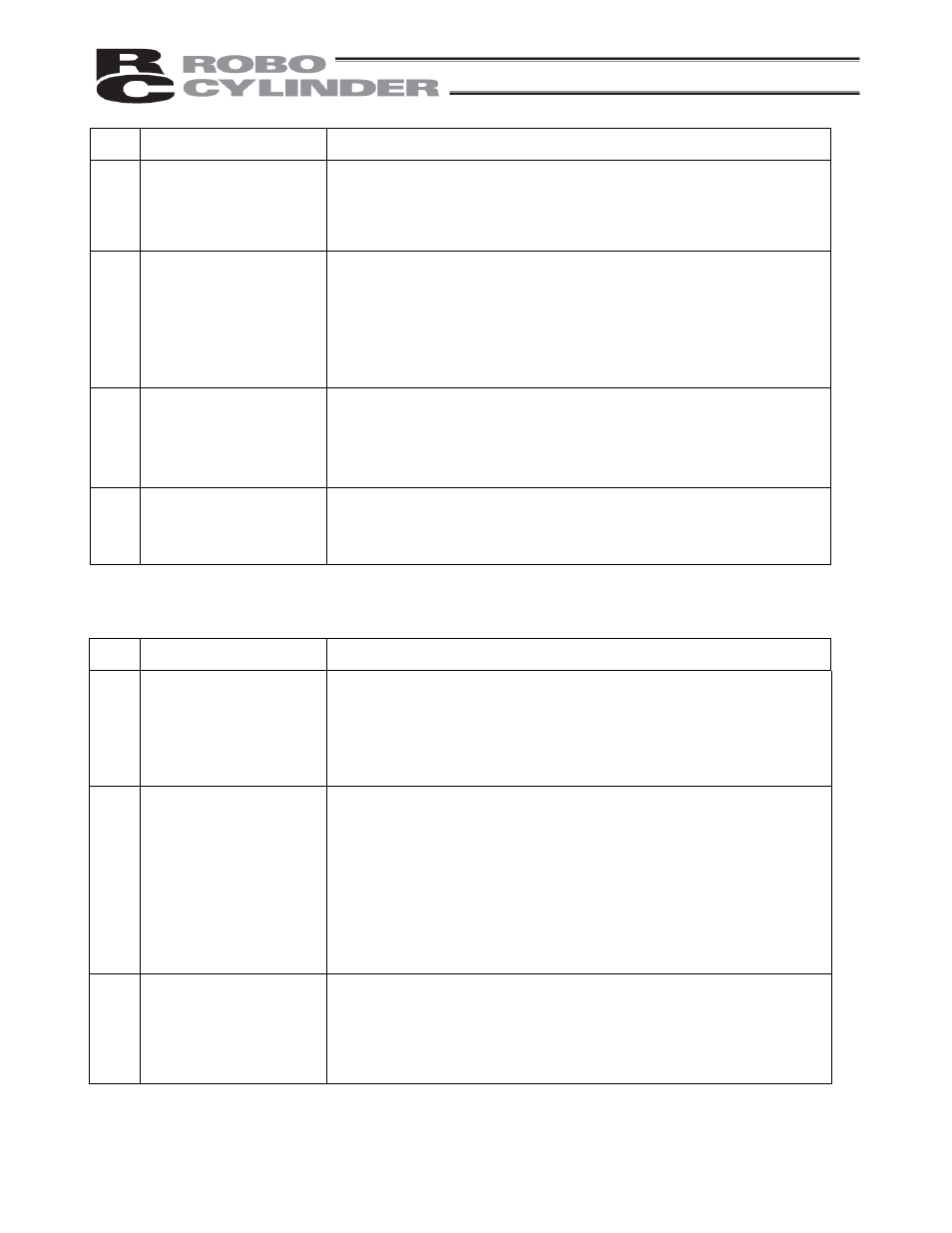

2) operation-cancellation level alarms, Operation-cancellation level alarms – IAI America RCP2-CF User Manual

Page 146

126

Code Error

name

Cause/Action

76

Soft reset during servo

ON

Cause: A soft reset command was sent while the servo was ON during

an operation by serial communication.

(PIO commands are excluded.)

Action: Send a soft reset command after confirming that the servo is

OFF.

77 Movement

command

during teaching

Cause: A position movement command was entered from a PC or

teaching pendant while the teaching mode was selected.

(Only the JOG inputs are enabled in the teaching mode.)

Action: Switch to the normal mode before entering a position

movement command.

(Turn OFF the MODE input signal and check if MODES is

OFF.)

78

EEPROM written during

teaching

Cause: Data was written from the PC or teaching pendant

simultaneously while the MODE signal was being input from

the PLC (teaching mode).

Action: Do not edit data from the PC or teaching pendant

simultaneously while a command is being issued from the PLC.

7A

ABS data backup battery

voltage low warning

Cause: The battery voltage was 4.4 V or below when the power was

input.

Action: Supply the power for at least 48 hours to charge the batteries.

(Moving the actuator will not affect the process of charging.)

(2) Operation-cancellation level alarms

Code Error

name

Cause/Action

B0

Bank 30 data error

Cause: Data in the parameter area is outside the input range or invalid.

(This alarm will not generate in normal parameter input

operation, but may occur during serial communication using

the PLC’s communication module.)

Action: Transfer data after confirming that the parameter values are

valid.

B1

Bank 31 data error

Cause: [1] A movement command was issued by selecting a number

to which no position data was registered.

[2] Position data value exceeds the soft limit setting.

[3] The timing of start signal is varied or too early.

Action: [1] Revise the sequence in such a way that unregistered

position numbers will not be selected.

[2] Change the position data to a value inside the soft limit

settings.

[3] The minimum timer setting may not be recognized

depending on the PLC. Pay attention to the timer setting.

BE

Home return timeout

Cause: Home return does not complete within the period set in the

applicable system parameter after the start of home return

operation.

(This alarm will not generate in normal operation.)

Action: The combination of controller and actuator may be wrong.

Please

contact

IAI.