4) ball screw accuracy – IAI America RCP2-CF User Manual

Page 122

102

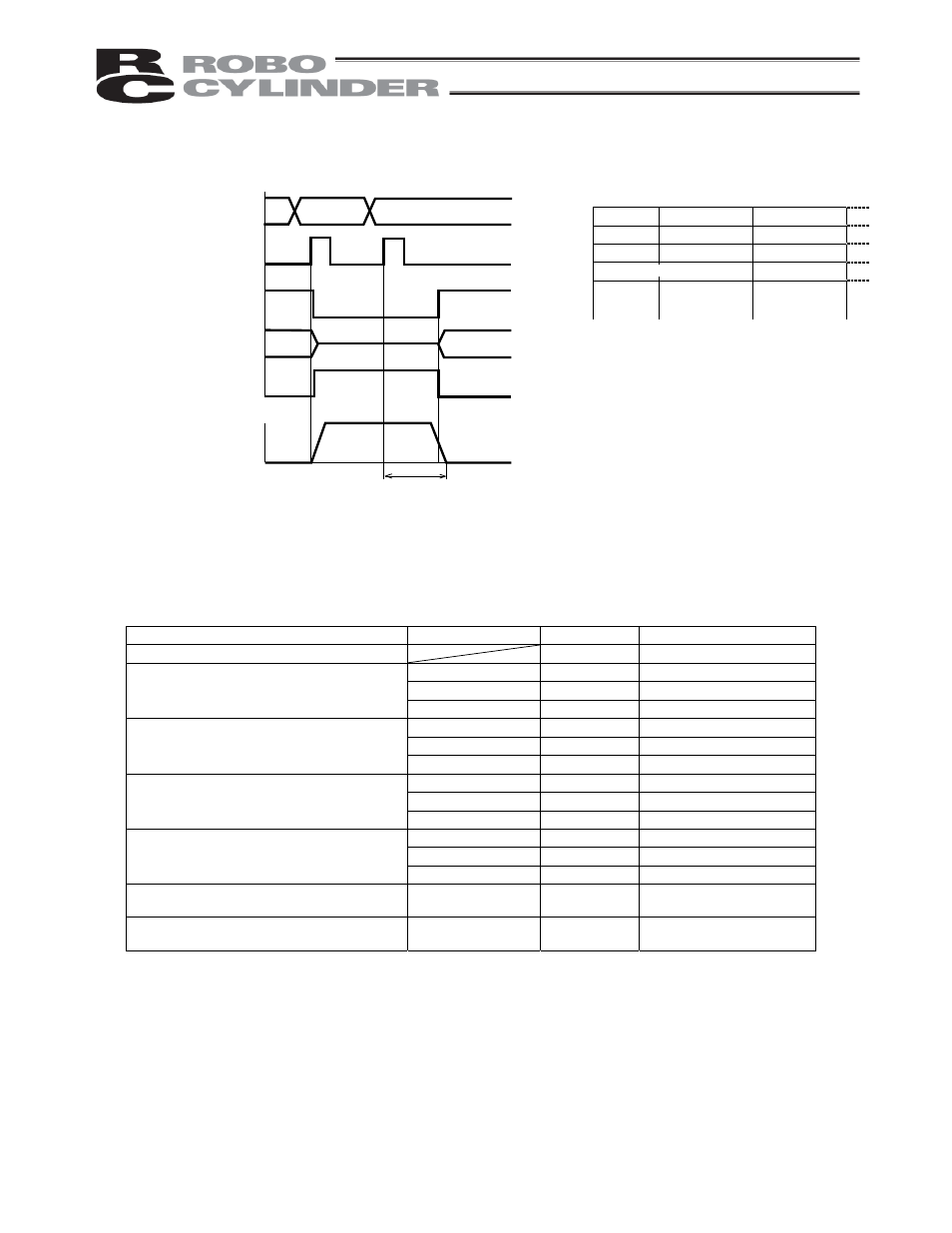

Example) If the start signal for movement to position 2 is input while the actuator is moving to position 1

in the push & hold mode, the actuator will move to the position 10 mm from where it was when

the input signal was input.

No. Position

Speed

0 *

*

1 50 100

2

10 100

(3) Cumulative errors due to repeated incremental moves

Position data is recognized only as a multiple of the minimum resolution. The minimum resolution is

determined by the lead and the number of encoder pulses. Therefore, a margin of error may occur

between the entered position value and the actual movement of the actuator. If an incremental move is

repeated, this error will accumulate.

The maximum error range for each actuator type is shown below:

RC model number

Speed type

Lead

Maximum error range

RCP2

-RPA

1 mm

0.00125 mm

Low speed

3 mm

0.00375 mm

Medium speed

6 mm

0.0075 mm

RCP2 -SA5

-SA6

-SS

(R)

High speed

12 mm

0.015 mm

Low speed

5 mm

0.00625 mm

Medium speed

10 mm

0.0125 mm

RCP2 -SM

-SMR

High speed

20 mm

0.025 mm

Low speed

2.5 mm

0.003125 mm

Medium speed

5 mm

0.00625 mm

RCP2 -RSA

-RXA

-RFA

High speed

10 mm

0.0125 mm

Low speed

4 mm

0.005 mm

Medium speed

8 mm

0.01 mm

RCP2 -RMA

-SA7

RCP2W -SA16

High speed

16 mm

0.02 mm

RCP2 -RTB-20

-RTC-20

Gear ratio

1/20

18

0.0225

RCP2 -RTB-30

-RTC-30

Gear ratio

1/30

12

0.015

Example) If an incremental move is repeated 10 times on a RCP2-SM high-speed controller, a maximum

error of 0.025 x 10 = 0.25 [mm] may generate with respect to the final position.

To eliminate these cumulative errors, an absolute command must be executed before the error tolerance is

exceeded.

(4) Ball screw accuracy

The accuracy of the ball screw used in the RCP2 conforms to C10 under the JIS standard.

=

Distance

10 mm

Command position

Start

Position complete

Completed position

Actuator movement

Speed

Position 1

Position 2

Position 2