Default positioning band (in-position), Default acceleration only max flag, Push & hold stop judgment period – IAI America RCP2-CF User Manual

Page 132

112

Default positioning band (in-position)

The factory setting is “0.10 [mm].”

When a target position is written to an unregistered position table or the current position is read in the teaching

mode, the setting in this parameter will be used as the positioning band data for the applicable position number.

Increasing the default positioning band will allow the position complete signal to be output early. Change the

setting in parameter No. 10, as necessary.

Default acceleration only MAX flag

To cause the actuator to decelerate gradually when stopping, a lower acceleration/deceleration should be set.

However, this will also reduce the acceleration.

This parameter allows for quick acceleration while reducing the deceleration.

This setting is permitted only when the actual payload is no more than one-third the rated load capacity.

Check the rated load capacity by referring to Appendix, “List of Supported Actuator Specifications.”

The factory setting is “0: [Disable].”

When a target position is written to an unregistered position table or the current position is read in the teaching

mode, the setting in this parameter will be used as the acceleration only MAX data for the applicable position

number.

To enable the default value, change parameter No. 11 to “1: [Enable].”

Push & hold stop judgment period

This parameter is used as a judgment condition when determining if the load was contacted and the push & hold

operation has completed.

The push & hold operation is judged complete if the current-limiting value set in the position table has been

maintained for the period set in parameter No. 6.

Set an optimal value by considering the shape and strength of the load, as well as the current-limiting value.

The minimum setting unit is “1 [msec],” and the maximum judgment period is “255 [msec].” The factory setting is

“255 [msec].”

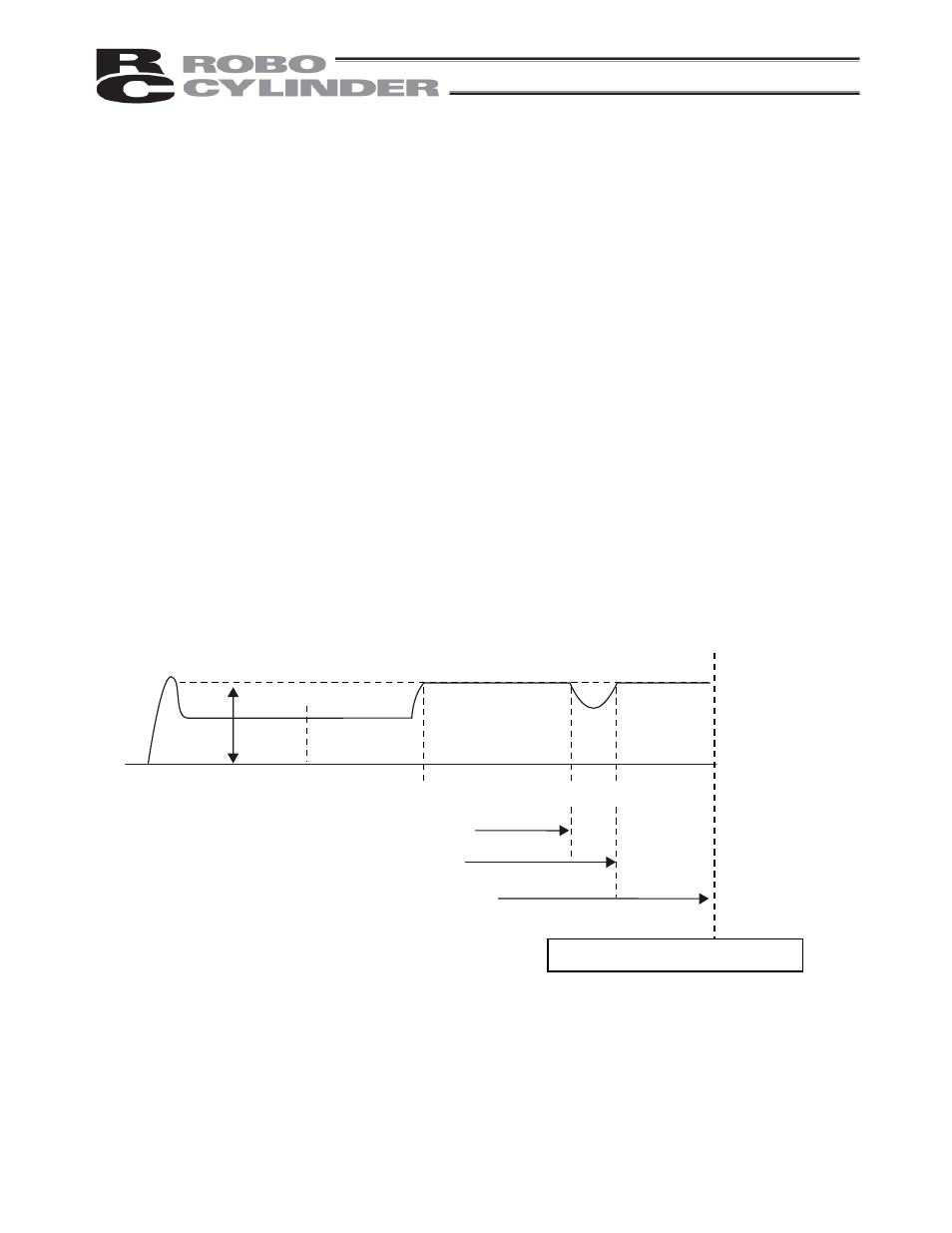

(Note) If the load has shifted and the current has changed during the push & hold judgment, the judgment

follows the timing chart shown below. This example assumes a judgment period of 255 msec.

After reaching the push current, it is maintained for 200 msec. The current drops during the subsequent 20-msec

period, and accordingly the count is decremented by 20. Therefore, when the operation is resumed the count will

start from 180. Since the count will reach 255 after 75 msec at the push current, the controller will determine that

the push & hold operation has completed.

In this example, the total judgment period is 295 msec.

Push current

20 msec

Start position

Target position

Counting starts

Counting continues until 200

Count is decremented to 180

Count is incremented to 255

Judgment of push & hold completion

75 msec