2 in, Ad with weight, 1 in – Emerson Process Management ROSEMOUNT 5300 User Manual

Page 219: 5 in., 2 in, In./cm, Rosemount 5300 series, Reference manual

Reference Manual

00809-0100-4530, Rev BA

July 2009

A-35

Rosemount 5300 Series

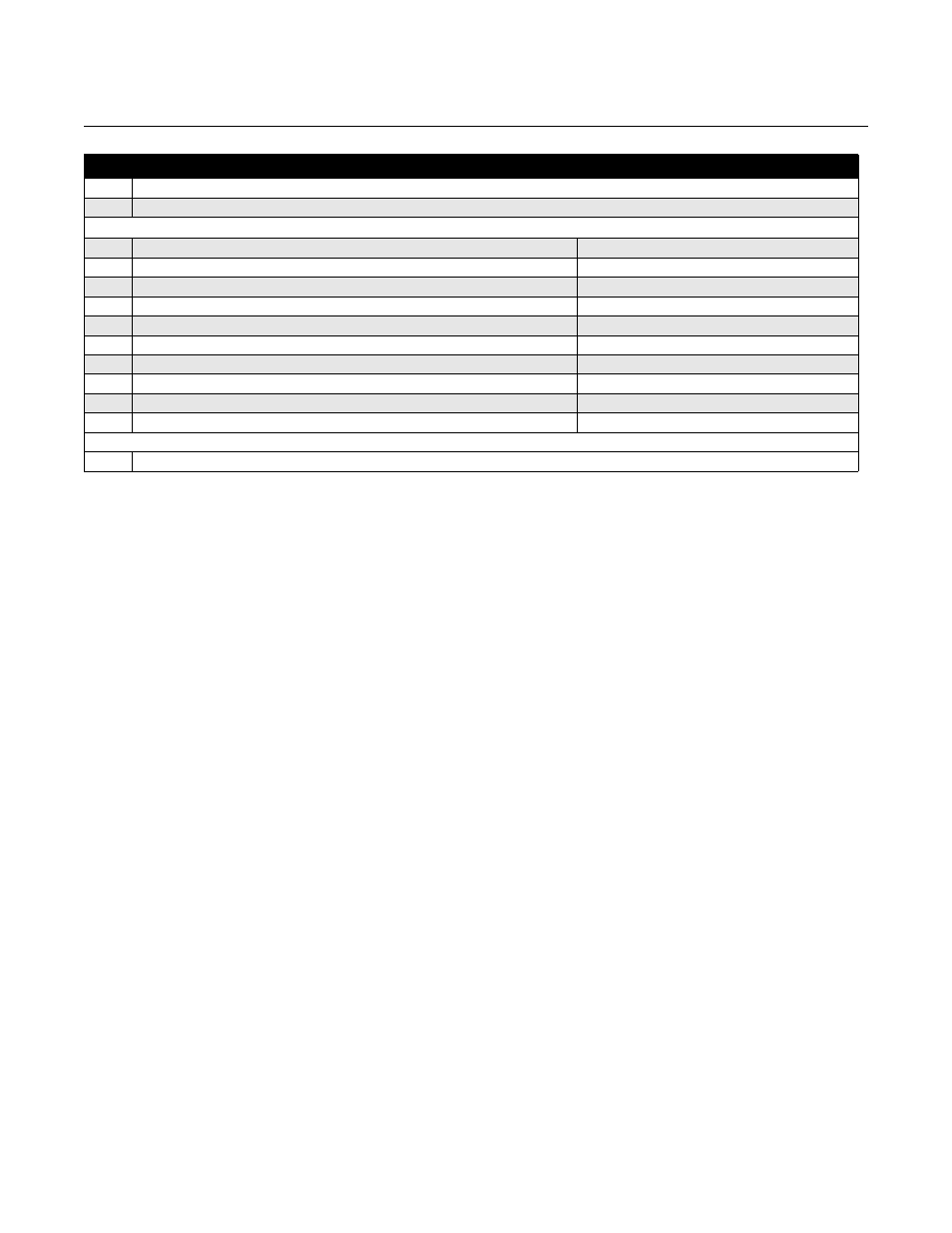

Code

Options (continued)

W2

Short weight for flexible single lead probe

(19)

BR

Mounting Bracket for 1.5 in. NPT Process Connection (RA)

(20)

Centering Discs

Outer Diameter

S2

2 in. Centering disc

(21)

1.8 in. (45 mm)

S3

3 in. Centering disc

2.7 in. (68 mm)

S4

4 in. Centering disc

3.6 in. (92 mm)

S6

6 in. Centering disc

5.55 in. (141 mm)

S8

8 in. Centering disc

7.40 in. (188 mm)

P2

2 in. Centering disc PTFE

(22)

1.8 in. (45 mm)

P3

3 in. Centering disc PTFE

2.7 in. (68 mm)

P4

4 in. Centering disc PTFE

3.6 in. (92 mm)

P6

6 in. Centering disc PTFE

5.55 in. (141 mm)

P8

8 in. Centering disc PTFE

7.40 in. (188 mm)

Special Certifications

Q8

Material Traceability Certification per EN 10204 3.1

(23)

(1) Process seal rating. Final rating depends on flange and O-ring selection.

(2) Requires option None for sealing (no O-ring).

(3) Welding Procedure Qualification Record Documentation will be supplied.

(4) For other materials, consult the factory.

(5) Consult the factory for this option.

(6) Requires High Temperature High Pressure (code H) or High Pressure (code P) probe.

(7) Only available with standard temperature and pressure (code S).

(8) Requires model 5301.

(9) Available in SST. Consult the factory for other materials.

(10) This is an HTHP probe.

(11) Extra length for fastening is added in factory.

(12) Probe weight included if applicable. Give the total probe length in feet and inches or meters and centimeters, depending on selected probe length unit.

If tank height is unknown, please round up to an even length when ordering. Probes can be cut to exact length in field. Maximum allowable length is

determined by process conditions. See “Mounting Considerations” on page 3-3 for more probe length guidance.

(13) Available in 316L SST (EN 1.4404). For other materials consult the factory.

(14) Available in 316L SST (EN 1.4404). For other materials consult the factory.

(15) Available in 316L SST. For other materials consult the factory.

(16) For standard tank connection only available with flange .

(17) For Material SST, Alloy C-276 and Alloy 400; Probe Type 3A, 3B, 4A, 4B, 4U, and 4V.

(18) Not available with PTFE covered probes.

(19) Only for Material of Construction code 1. For other materials, consult the factory.

(20) Only for Standard Temperature and Pressure.

(21) Available for SST and Alloy C-276 probes, type 2A, 4A, 4B, and 5A. Same disc material as probe material.

(22) Available for SST probes, type 2A, 4A, 4B, 5A and 6A except for HTHP.

(23) Certificate includes all pressure retaining wetted metal parts.