Safe direction monitoring (sdm) – Rockwell Automation 2094-EN02D-M01-S1 Kinetix 6200 and Kinetix 6500 Safe Speed Monitoring Safety Reference Manual User Manual

Page 108

108

Rockwell Automation Publication 2094-RM001C-EN-P - May 2013

Chapter 9

Safe Maximum Speed and Direction Monitoring

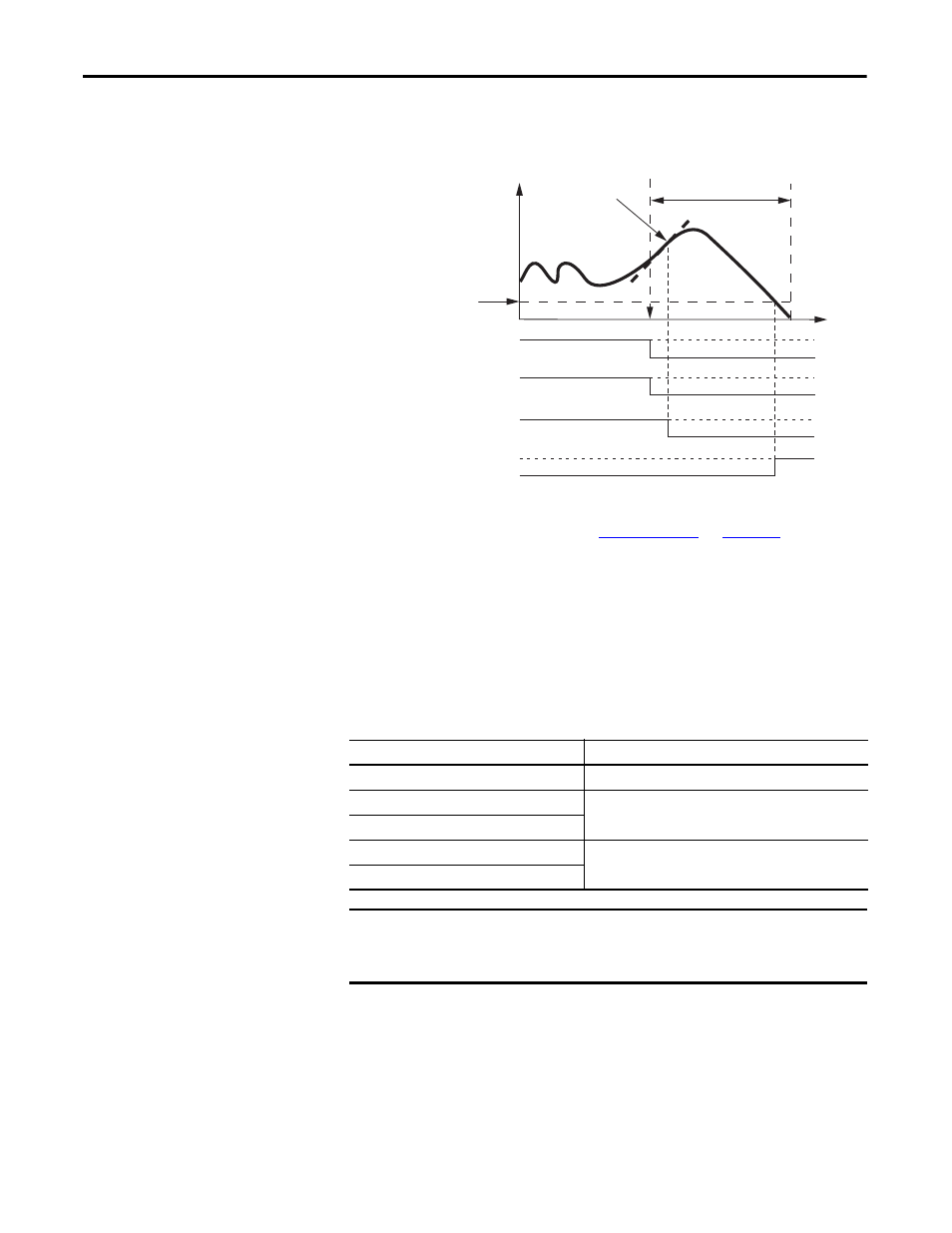

Figure 44 - Acceleration Fault When [Safe Maximum Acceleration Monitoring Stop Behavior] Set

to ‘Use Safe Torque Off with Check for Standstill’

(1) This signal is internal to the drive.

For more information about faults, see

Safe Direction Monitoring

(SDM)

When configured for Safe Direction Monitoring, the drive monitors the

feedback direction and initiates the configured Stop Category when motion in

the illegal direction is detected. You configure Safe Direction Monitoring by

using the [Enable Safe Direction Monitoring] parameter. This parameter also

determines the direction, positive or negative, that motion is allowed.

Table 31 - Enable Safe Direction Monitoring

You can configure a position limit, in encoder units, tolerated in the wrong

direction before a Direction fault occurs, by using the [ Jitter Tolerance]

parameter.

Stop Request

Stop Delay

Acceleration

Fault

Standstill Speed

Speed

Time

Motion Power

(1)

DC_Out

SS_In

SS_Out

[Enable Safe Direction Monitoring] Parameter

Description

Disabled

Safe Direction Monitoring is disabled.

Positive Always

Safe Direction Monitoring is active any time the configuration is

valid and not Disabled.

Negative Always

Positive During SLS

Safe Direction Monitoring is performed only when the drive is

actively monitoring Safe Limited Speed.

Negative During SLS

IMPORTANT

Be sure to set the [Primary Feedback Polarity] and [Secondary Feedback

Polarity] configuration parameters properly for a consistent direction

between encoder 1 and encoder 2.