Plc designer v2.x| lenze application samples – Lenze PLC Designer V2.x User Manual

Page 262

PLC Designer V2.x| Lenze Application Samples

The L_SCS_DriveECS.lib library

L_SCS_PosiShaft - actuation of the ECS servo system

262

L

1.3 EN - 07/2012

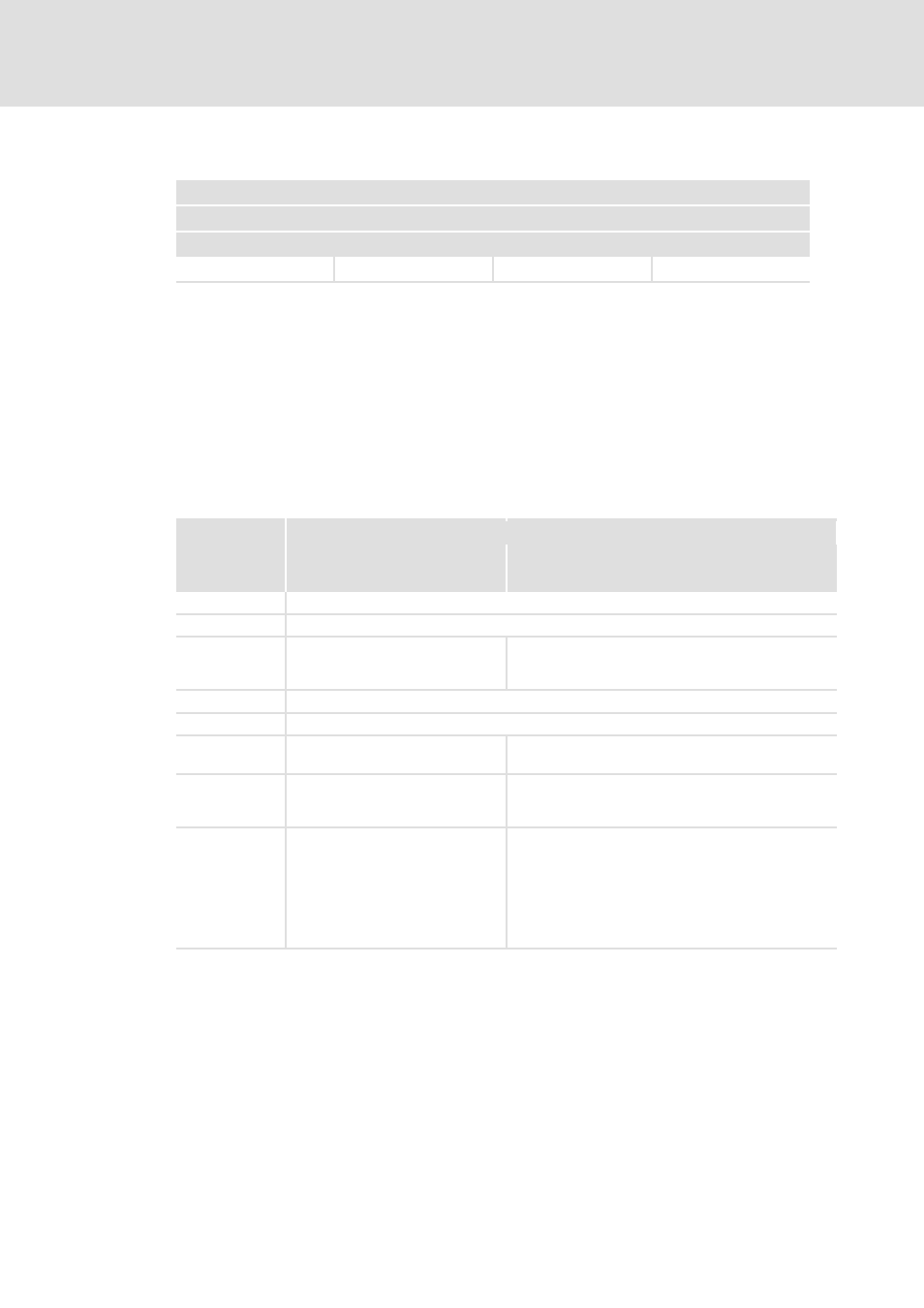

Assignment of the process data from the controller:

13.3.2.2

Monitor data words from the controller (tx_par1 and tx_par2)

The monitor data words "tx_par1" and "tx_par2" can be assigned via control bits in

control word Ctrl1 with different display values:

ƒ Control bit 0 ("Ctrl1-Func1")

ƒ Control bit 1 ("Ctrl1-Func2")

ƒ Control bit 2 ("Ctrl1-Func4")

The following assignment of the monitor data words can be set via the control bits:

Word 1

Word 2

DWord (word 3 + word 4)

LOW byte

HIGH byte

LOW byte

HIGH byte

LOW word

HIGH word

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Status word Stat1

Status word Stat2

tx_par1

tx_par2

Control bits 0..2

in the control

word

Ctrl1 [binary]

Monitor data word

tx_par1

tx_par2

...000

Actual position (2

16

== 1 position encoder revolution)

...001

FollowErr (2

16

== 1 position encoder revolution)

...010

Actual speed value nact

Scaling: 214 == C0011 (maximum

speed)

Current torque Mact

Scaling: 214 == C0057 (Maximum torque calculated)

...011

Not assigned

...100

Not assigned

...101

Fault number

DCTRL_wStat (C0150)

Bit assignment: see code list of the ECS device

...110

Profile generator status (C3066)

Bit assignment: see code list of the

ECS device

Not assigned

...111

AIn1 DigIn

Bit assignment:

• Bit 0 ... 12: Image of analog input

• Bit 13, 14, 15: 0 (no function)

DigIn

Bit assignment:

• Bit 0 (X6/DI1): Image digital input 1

• Bit 1 (X6/DI2): Image digital input 2

• Bit 2 (X6/DI3): Image digital input 3

• Bit 3 (X6/DI4): Image digital input 4

• Bit 4 ... 15: 0 (no function)