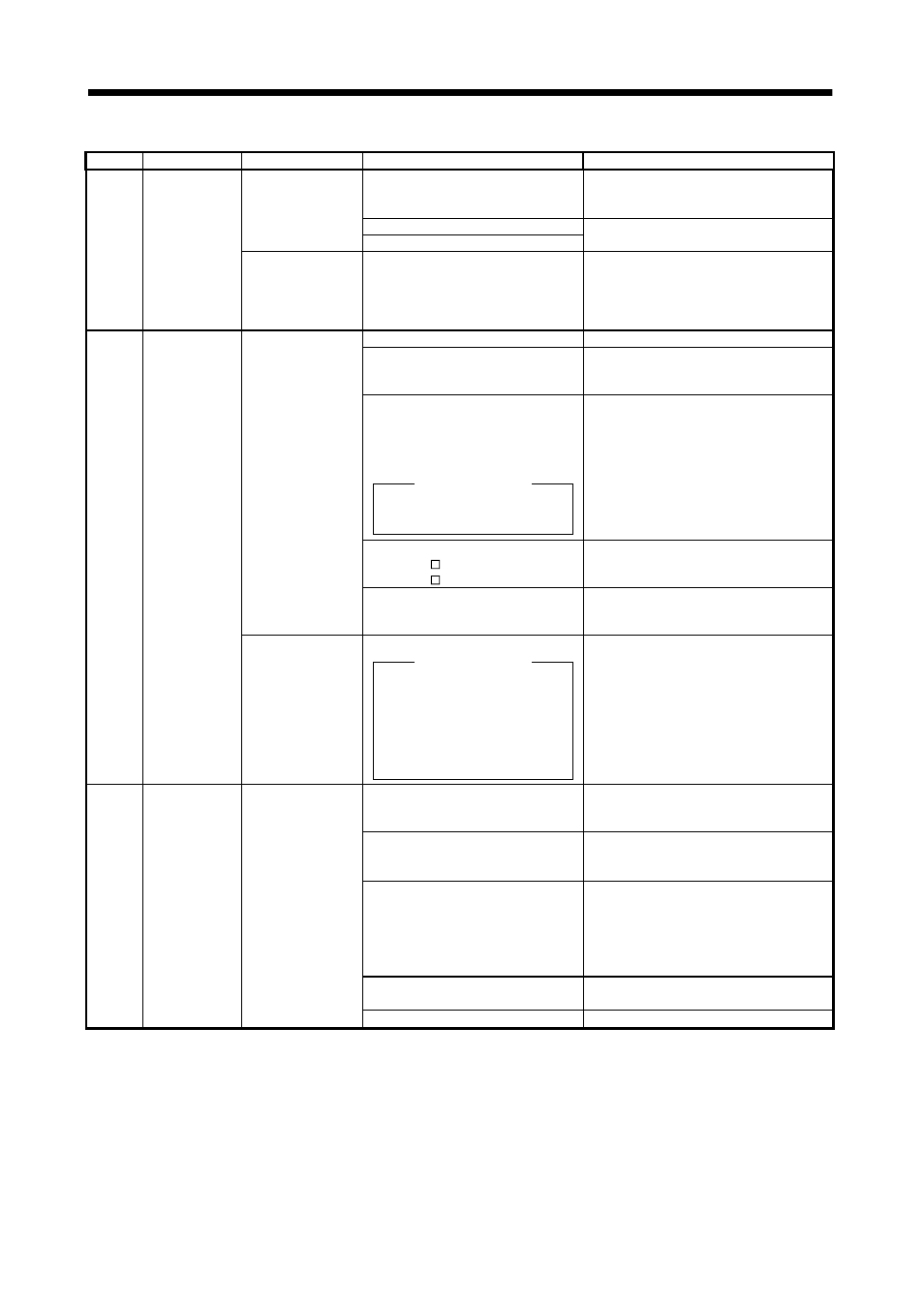

Troubleshooting – MITSUBISHI ELECTRIC MELSERVO MR-J2S- A User Manual

Page 202

10 - 9

10. TROUBLESHOOTING

Display

Name

Definition

Cause

Action

1. Reduced voltage of super capacitor

in encoder

After leaving the alarm occurring for a few

minutes, switch power off, then on again.

Always make home position setting again.

2. Battery voltage low

Absolute position

data in error

3. Battery cable or battery is faulty.

Change battery.

Always make home position setting again.

AL.25

Absolute

position erase

Power was switched

on for the first time

in the absolute

position detection

system.

4. Super capacitor of the absolute

position encoder is not charged

After leaving the alarm occurring for a few

minutes, switch power off, then on again.

Always make home position setting again.

1. Wrong setting of parameter No. 0 Set correctly.

2. Built-in regenerative brake

resistor or regenerative brake

option is not connected.

Connect correctly

3. High-duty operation or continuous

regenerative operation caused the

permissible regenerative power of

the regenerative brake option to

be exceeded.

Checking method

Call the status display and check

the regenerative load ratio.

1. Reduce the frequency of positioning.

2. Use the regenerative brake option of

larger capacity.

3. Reduce the load.

4. Power supply voltage is abnormal.

MR-J2S- A:260VAC or more

MR-J2S- A1:135VAC or more

Review power supply

Permissible

regenerative power

of the built-in

regenerative brake

resistor or

regenerative brake

option is exceeded.

5. Built-in regenerative brake

resistor or regenerative brake

option faulty.

Change servo amplifier or regenerative

brake option.

AL.30

Regenerative

alarm

Regenerative

transistor fault

6. Regenerative transistor faulty.

Checking method

1) The regenerative brake option

has overheated abnormally.

2) The alarm occurs even after

removal of the built-in

regenerative brake resistor or

regenerative brake option.

Change the servo amplifier.

1. Input command pulse frequency

exceeded the permissible

instantaneous speed frequency.

Set command pulses correctly.

2. Small acceleration/deceleration

time constant caused overshoot to

be large.

Increase acceleration/deceleration time

constant.

3. Servo system is instable to cause

overshoot.

1. Re-set servo gain to proper value.

2. If servo gain cannot be set to proper

value:

1) Reduce load inertia moment ratio; or

2) Reexamine acceleration/

deceleration time constant.

4. Electronic gear ratio is large

(parameters No. 3, 4)

Set correctly.

AL.31

Overspeed

Speed has exceeded

the instantaneous

permissible speed.

5. Encoder faulty.

Change the servo motor.