Signals and wiring – MITSUBISHI ELECTRIC MELSERVO MR-J2S- A User Manual

Page 107

3 - 60

3. SIGNALS AND WIRING

3.11.2 For the servo amplifier produced earlier than Dec. 2005

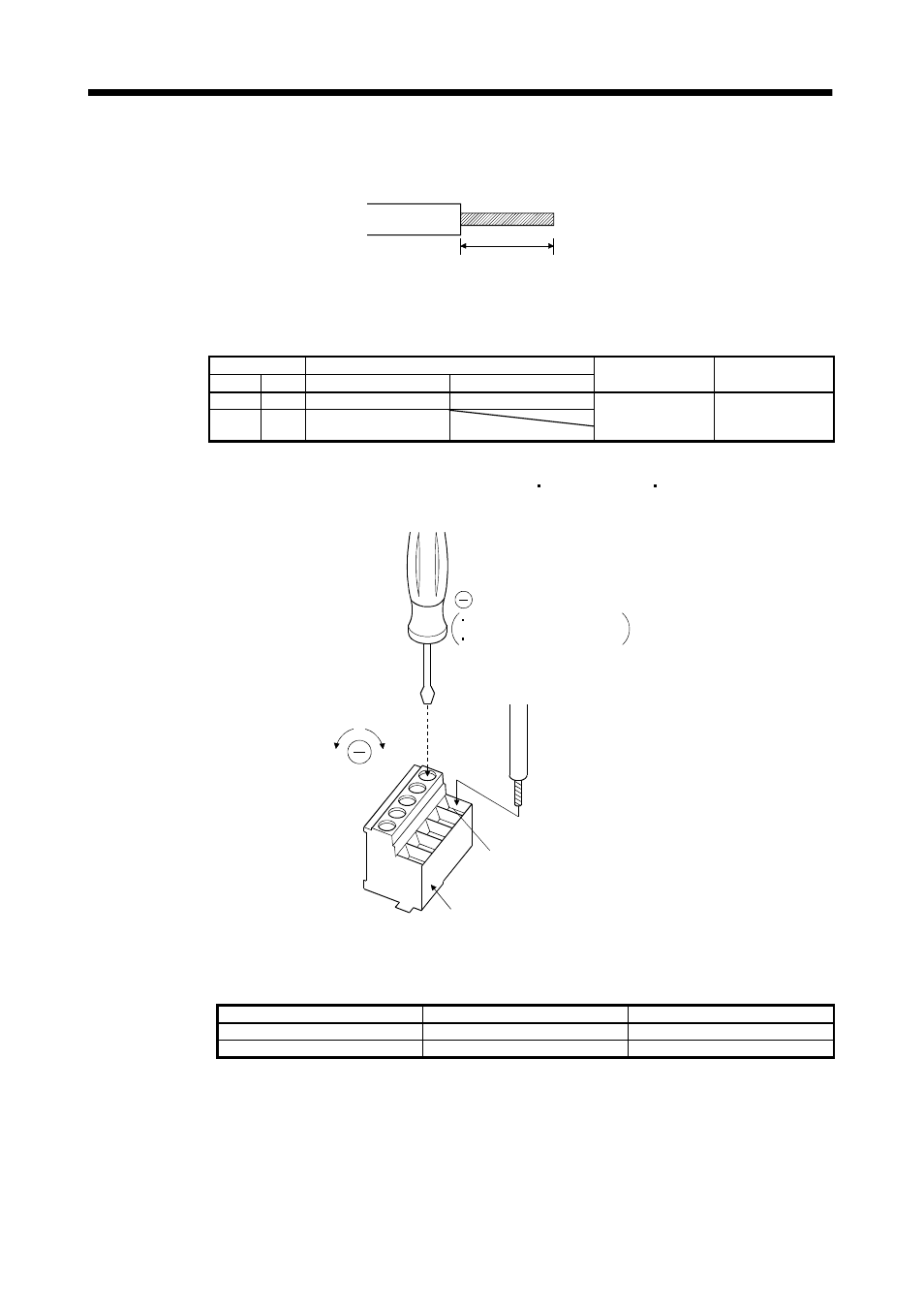

(1) Termination of the cables

Solid wire: After the sheath has been stripped, the cable can be used as it is.

Approx. 10mm

(0.39inch)

Twisted wire: Use the cable after stripping the sheath and twisting the core. At this time, take care to

avoid a short caused by the loose wires of the core and the adjacent pole. Do not solder

the core as it may cause a contact fault. Alternatively, a bar terminal may be used to put

the wires together.

Cable Size

Bar Terminal Type

[mm

2

] AWG

For 1 cable

For 2 cables

Crimping Tool

Maker

1.25/1.5

16

AI1.5-10BK

AI-TWIN

×

1.5-10BK

2/2.5

14

AI2.5-10BU

CRIMPFOX ZA 3

or

CRIMPFOX UD 6

Phoenix Contact

(2) Connection

Insert the core of the cable into the opening and tighten the screw with a flat-blade screwdriver so that

the cable does not come off. (Tightening torque: 0.3 to 0.4N m(2.7 to 3.5 lb in)) Before inserting the

cable into the opening, make sure that the screw of the terminal is fully loose.

When using a cable of 1.5mm

2

or less, two cables may be inserted into one opening.

To loosen.

To tighten.

Opening

Control circuit terminal block

Cable

Flat-blade screwdriver

Tip thickness 0.4 to 0.6mm

Overall width 2.5 to 3.5mm

Use of a flat-blade torque screwdriver is recommended to manage the screw tightening torque. The

following table indicates the recommended products of the torque screwdriver for tightening torque

management and the flat-blade bit for torque screwdriver. When managing torque with a Phillips bit,

please consult us.

Product

Model

Maker/Representative

Torque screwdriver

N6L TDK

Nakamura Seisakusho

Bit for torque screwdriver

B-30, flat-blade, H3.5 X 73L

Shiro Sangyo