1 area/segment/edge, 2 normal mode – KEYENCE LS-5000 User Manual

Page 28

Chapter 5 Outline of Measurements

22

5

5.1

Area/Segment/Edge

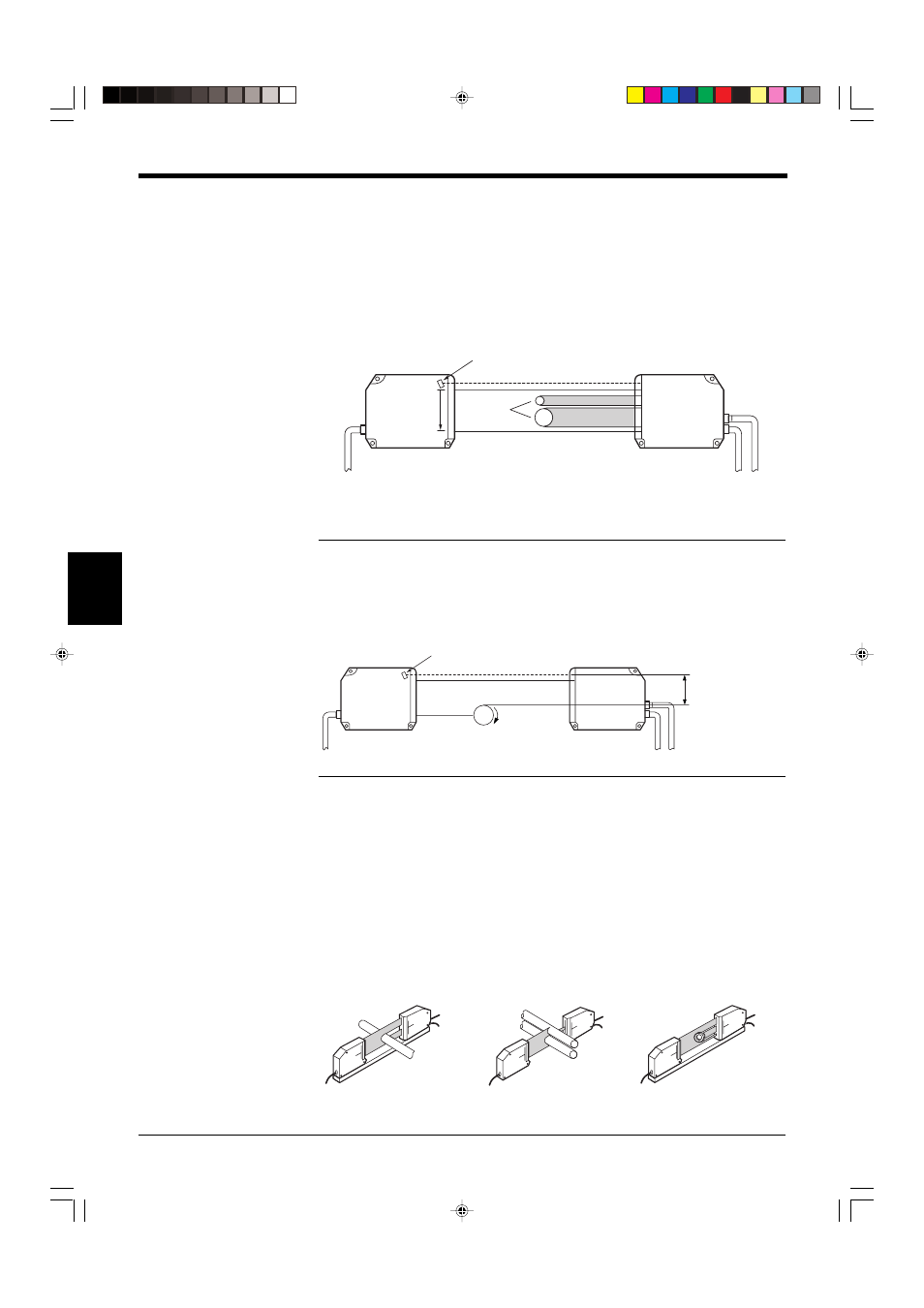

When a target is placed in the measuring area, there are areas where the laser

beam is received (laser beam enters the receiver), and where the laser beam is

interrupted by the target (shadow of the target is projected on the receiver). The

border between the light and dark areas is called “EDGE”. Each section divided by

the edge is called a “SEGMENT”. The measurement "AREA" is determined by two

edges and includes all "SEGMENTS" between these two edges.

*

The edge number is counted in the laser scanning direction starting at T.EDGE

(top edge).

Note: EDGE 0

The position of the photodiode for synchronization is called “EDGE 0”.

EDGE 0 can be used as a reference point during roller oscillation measurement or

sheet edge control. (No reference edge is required.)

Example: Roller oscillation measurement

5.2

Normal Mode

➮ For the setting procedure, see p. 39.

The LS-5000 series has two measuring modes; NORMAL and PITCH. NORMAL

mode provides four types of measurement3: “DIA”, “T.EDGE (Top Edge)”,

“B.EDGE (Bottom Edge)” and “SEG(m,n)”.

The function of each mode is described below. Select the mode that suits your

measurement condition.

Edge 0

Edge 1

Edge 2

Edge 3

Edge 4

Edge 5 (n-1)

Edge 6 (n)

Photodiode for synchronization

Laser

scanning

direction

Target

Transmitter

Receiver

Photodiode for synchronization

Transmitter

Receiver

Roller

Rotating

This width can be

measured when

SEG(m,n) is set to (0,2) in

Normal mode.

DIA mode

Measurement of outer diameter

of rod or electric wire

T.EDGE/B.EDGE modes

Measurement of gap

between rollers or position

of target

edge

SEG(m,n) mode

Setting the measurement

position to measure inner

diameter using

a bearing